Chinese 3D printer manufacturer Farsoon Technologies has showcased its Dual-Laser Flight technology on its 403P printing platform for the first time at TCT Asia 2021 in Shanghai.

The firm also announced it has expanded its material portfolio for the technology with the addition of two new polymer powders and another third party material.

The new dual-laser configuration of Farsoon’s LPBF-based Flight technology is designed to significantly increase manufacturing turn-over rate while accelerating product-to-market cycles of industrial-grade parts such as robotics, electronic components, and battery units.

Farsoon’s Flight technology

Farsoon’s Flight Technology was first introduced in February 2019 with the launch of the firm’s 403P system, a medium format polymer SLS machine designed for heavy-duty professional applications.

Also known as Fiber Light technology, Flight technology is 3D printing process designed to enhance the productivity of plastic laser sintering. The process replaces standard CO₂ laser technology with powerful fiber lasers in order to provide increased laser longevity and energy absorption.

In turn, this expands the range of processable materials for Farsoon’s 3D printing systems and also allows the powder to be fully sintered in a shorter amount of time. The high-speed technology was rolled out for beta testing in October 2019, and has since been continually developed by Farsoon for compatibility with its other systems.

The company’s machine portfolio consists of several machines for both polymer and metal processing, each of which is an open platform to give users access to advanced parameters and third party material usage.

According to Farsoon, its Flight technology “unlocks the next level of LPBF productivity” for industrial-grade parts, offering extremely fine details with a minimum wall thickness of just 0.3 mm.

The combination of high-speed sintering and high-feature resolution has opened up multiple applications for the series production of parts including electronic components, robotics, specialized tools and models, battery units, filter modules, and many consumer products.

Last year, Farsoon implemented its proprietary Flight Technology into its new high-temperature 252P series of polymer SLS 3D printers.

Dual-Laser Flight Technology

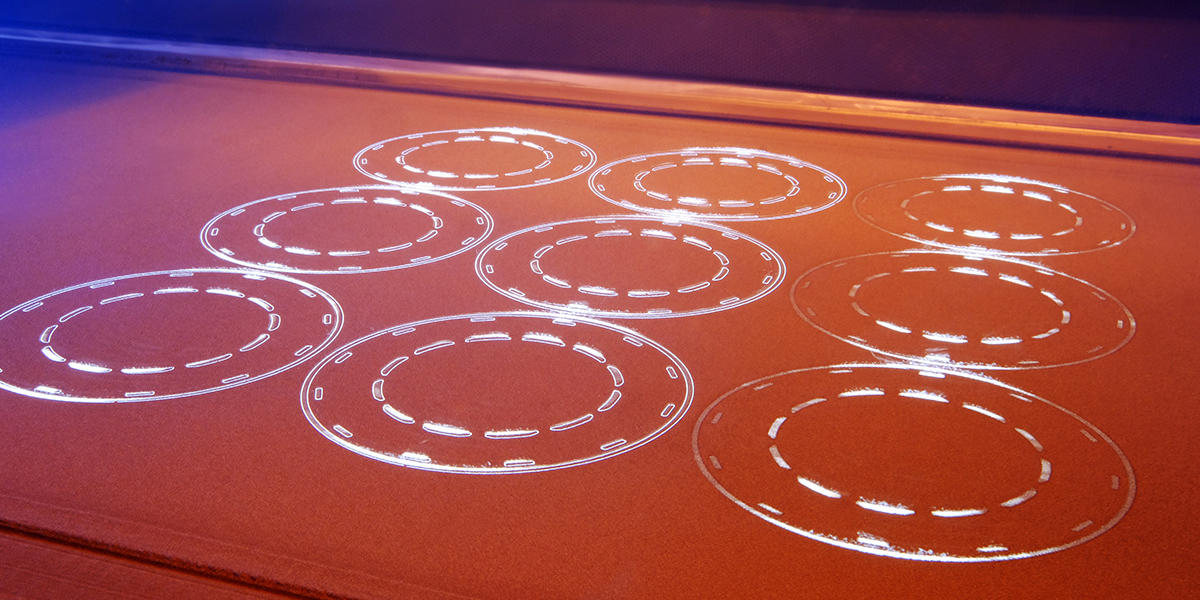

The dual-laser configuration of Farsoon’s Flight technology makes use of two powerful 300w fiber lasers and two dynamic optical systems to create two ultra-fine laser spots with scanning speeds up to 20m/s.

Compared to the single laser configuration, the Dual-Laser Flight technology offers between a 50-90 percent higher production volume rate, and reportedly offers three to four times the production yield of a single CO₂ laser machine.

When used on Farsoon’s 403P printing system, the dual-laser configuration is capable of achieving two full builds of 400 x 400 x 450 mm in a single day. As a result, machine uptime is significantly improved and maximum throughout yield per floor area is achieved within the same time frame.

Farsoon showcased the dual-laser configuration on its 403P platform at TCT Asia, and is planning to integrate the technology into its HT1001P CAMS platform, which is equipped with a build cylinder measuring 1000 x 500 x 450 mm.

Expanding Flight technology’s material portfolio

Also announced at TCT Asia 2021 were two new PA12-based powders specifically engineered for Farsoon’s Flight Technology.

The first, FS3300PA-F, is optimized for fiber laser processing and produces parts that offer a decent balance of mechanical and thermal properties suitable for a wide range of industrial applications.

The second, FS3401GB-F, is a glass bead reinforced powder suitable for end-use applications requiring both functionality and mechanical strength. Parts printed in the material display substantial dimensional stability alongside good thermal and abrasive resistance, making them well-suited for 3D printed industrial components such as automotive engine systems and electrical tools.

Users are able to utilize Farsoon’s polymer powder management system (PMS), released at Formnext Connect last year, in order to achieve a powder refresh rate of up to 20 percent virgin material for both the new PA12-based powders and reduce manufacturing cost per part. To do this, the PMS integrates powder recycling and storage, new powder supply, high-speed mixing, and sieving powder handling processes.

In addition to expanding its own powder portfolio, Farsoon will also include a specialized TPU material from its partner LEHVOSS Group for use with its Flight technology. The LUVOSINT TPU X92A-1064 WT material is light grey in color and has been successfully tested on Farsoon’s Flight 403P and 252P printing systems.

According to the company, the material offers a convenient processing window and good recyclability, while producing printed parts with good elongation and size stability. These features make the material suited to applications such as tailored shoe soles, parts with complex tube geometries, and even medical applications.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows the Dual Laser Flight technology sintering process. Photo via Farsoon Technologies.