Swedish metal 3D printer manufacturer Digital Metal has launched what it describes as the “world’s first” automated depowdering station for binder jet systems.

Known as the DPS 1000, Digital Metal’s latest machine is designed to mechanize post-print powder recycling, enabling users to more easily serially-manufacture binder jetted parts. As one of the first to install the new system, Fraunhofer IAPT now intends to deploy it as a means of aiding its wider research into the material-efficient industrialization of 3D printing.

According to Alexander Sakratidis, Sales and Marketing Manager at Digital Metal, installing the automated depowering unit should allow the institute’s engineers to spend more time on value-generating tasks moving forwards. “A key benefit of the DPS 1000 for Digital Metal customers, is that it will free up time,” said Sakratidis, “it also brings consistency by removing the human factor from the equation.”

Digital Metal’s jetting approach

Operating as a subsidiary of alloy powder manufacturer Höganäs AB, Digital Metal has built up a broad ecosystem of products around its unique binder jetting technology over the past four years, and it now markets its DM P2500 3D printer, related materials and of course, the new DPS 1000 depowdering station.

Based around its proprietary technology, Digital Metal’s DM P2500 is built to enable precise production at scale, and it features automatically-calibrated moving parts capable of printing with an accuracy of just 1 µm. Since its launch in 2017, the system has found applications within both automotive and aerospace, and been installed at the Manufacturing Technology Centre as well, for research purposes.

In the past, Digital Metal has also sought to expand its machine’s capabilities by providing its users with a pure copper powder to 3D print with, and releasing a software upgrade that tripled its speed. Likewise, the firm has experimented with robotically-loading the DM P2500, and the DPS 1000 appears to be the next logical step in its mission to automate the system, and unlock its throughput potential.

Automated depowdering at scale

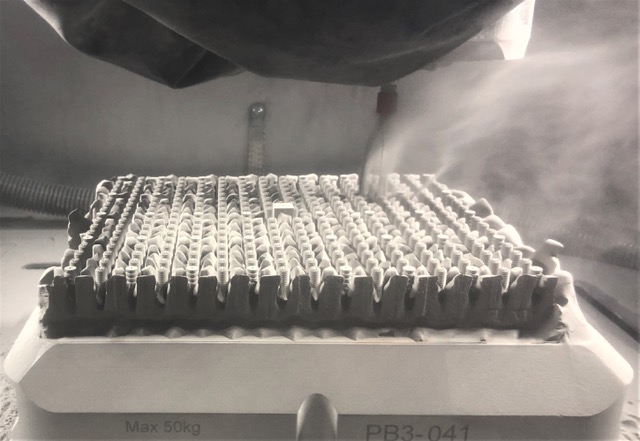

Digital Metal’s new system is effectively a semi-automatic depowdering station that allows adopters to safely collect and reuse loose powder for future jobs. In practise, the machine is able to achieve this thanks to its automated cleaning nozzles, which remove any remaining material from printed parts using compressed air, while if needed, complex components can also be put back in for manual processing.

By performing this initial post-processing step on the behalf of its users, Digital Metal says that the DPS 1000 unlocks “high volume production,” and that it could help raise the throughput its binder jetting clients are able to achieve, without sacrificing the accuracy or reliability of the resulting components.

“Metal binder jetting will enhance productivity and precision while at the same time reducing costs of metal AM, which opens the door for series production,” explains Dr. Philipp Imgrund, Head of the AM Processes Department at Fraunhofer IAPT. “However, one major technical challenge is the depowdering of green parts, and we see a huge potential in working on automation solutions in this context.”

For its part, Fraunhofer IAPT has now become one of the first to adopt Digital Metal’s new unit, installing it alongside one of the firm’s DM P2500 3D printers. While using the DPS 1000, Fraunhofer’s engineers are already said to be pleased with its ability to depowder sophisticated parts, and through working with Digital Metal, the institute believes that it could uncover exciting research opportunities in future.

“With this system, we can easily test multiple different powders to enhance print quality and make more precise predictions on the shrinking of the sintering process,” added Imgrund. “We also appreciate the collegial and professional atmosphere when working with Digital Metal. It makes it easy to find common ground for innovative projects.”

“It convinces with its precision, and even very delicate structures can be printed.”

Advances in binder jetting

So far, 2021 has witnessed a plethora of binder jetting advances, including technological developments, newly-qualified materials and the unlocking of novel applications. Just last month, Desktop Metal became the first to qualify 4140 low-alloy steel for its Single Pass Jetting technology, providing its Production System users with a new material capable of yielding automotive oil & gas or tooling parts.

In fact, binder jetting is increasingly finding mainstream automotive applications, and Volkswagen has announced plans to deploy the technology at its plant in Wolfsburg, Germany. Working with HP and Siemens, the firm aims to adopt binder jetting as a means of reducing its costs and increasing its factory’s productivity.

Similarly, manufacturing service provider FreeFORM Technologies recently revealed that it’s using ExOne’s binder jetting technology to produce lightweight automotive tooling. In one such case, the company has been able to create a complex end-of-arm tooling part, for its client, industrial automation firm Allegheny Electric Service.

The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Digital Metal’s new DPS 1000 depowdering system. Image via Digital Metal.