Subscribe to the 3D Printing Industry YouTube channel for the latest 3D printing webinars, video shorts, and reviews.

Industrial 3D printer manufacturer Desktop Metal has become the first company to qualify 4140 low-alloy steel for use with metal binder jetting technology.

Qualified for use with the company’s Production System 3D printer, 4140 is now processable with Desktop Metal’s patent-pending Single Pass Jetting (SPJ) technology. The metal is considered one of the most versatile low-alloy steels, with applications in a whole host of industries such as automotive, oil & gas, and manufacturing tooling. Desktop Metal’s latest achievement means customers will now be able to 3D print end-use 4140 parts at high volumes.

Jonah Myerberg, co-founder and CTO of Desktop Metal, states, “4140 has been a challenging material for metal binder jetting because of its low alloyed content, tight carbon control requirements, and low ignition energy, which together require advanced binder chemistry, as well as extensive printing and sintering optimization and atmospheric controls for safe processing.”

3D printing 4140 low-alloy steel

4140 steel is characterized by its extensive usefulness, combining toughness, high strength, and abrasion and impact resistance. The material is also heat treatable, seeing common use in everything from gears and couplings to spindles, nuts and bolts.

The ability to 3D print the metal will help customers eliminate the use of tooling altogether, while also reducing material use, slashing lead times, and minimizing part costs. In fact, Desktop Metal has already put its 4140 process to the test with a number of 3D printed end-use components, each of which meet the MPIF 35 standards set by the Metal Powder Industries Federation.

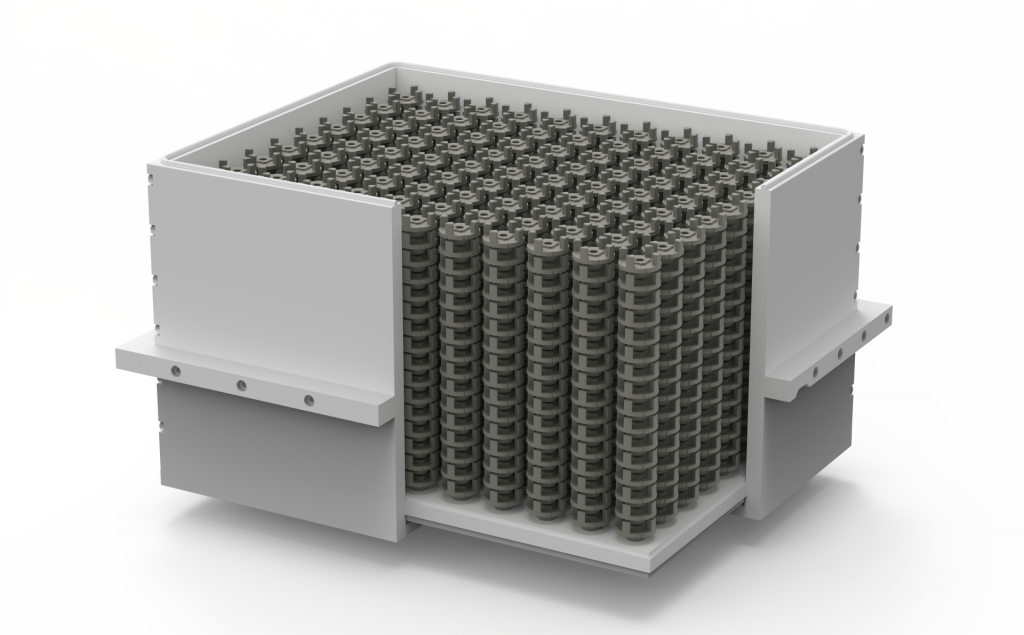

A key component of the Production System’s success is its incredible speed and throughput capabilities, as it is designed to be up to 100x faster than comparable powder bed fusion 3D printers. As well as 4140, the technology is compatible with stainless steel grades, tool steel grades, aluminum, and even titanium.

Myerberg adds, “With the speed of the Production System, businesses can now use binder jetting to print complex 4140 parts at competitive costs while maintaining the strength and mechanical properties of traditionally manufactured alternatives. This is a game-changing solution for manufacturers who have been tied to time-consuming and expensive machining and conventional tool-based manufacturing processes.”

Joints, gears, and other mechanical parts

The first of the demonstration components 3D printed by the company is a power steering joint, which is used to transfer power from a car’s motor to the steering shaft. The strength and hardness provided by 4140 were crucial here, enabling the part to withstand extended periods of stress during service. To conventionally manufacture the part, a costly and time-inefficient mold is usually required, but the large-format Production System P-50 is able to 3D print quantities of up to 1.2 million every year at a cost of just $2.45 per part.

Similarly, herringbone gears, which are used in all manner of industrial tooling, require hardness and excellent fatigue resistance. Desktop Metal was able to 3D print a geometrically optimized herringbone gear using its Production System, lightweighting the part to save on material costs and improve mechanical performance. The company claims it is possible to 3D print up to 200,000 units of the part every year, with 120 gears nested in a single build.

The advancement of metal binder jetting technology has given rise to a plethora of new material compatibilities like 4140. Earlier this year, Desktop Metal and materials developer Uniformity Labs announced the launch of a sinterable aluminum powder for use with the company’s binder jet 3D printing technology. It is intended as a low-cost raw material option for manufacturers looking to 3D print fully dense, sinterable 6061 aluminum alloy parts.

Elsewhere, industrial 3D printer manufacturer Digital Metal announced the launch of a pure copper powder, DM Cu, for use with its own binder jet 3D printing technology. The material is known for its excellent thermal conductivity, making it the universal choice for heat transfer components such as heat exchangers, piping, and heat sinks for engines and electronics.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a Production System manufacturing facility. Photo via Desktop Metal.