Industrial 3D printer manufacturer Digital Metal has announced the launch of a new pure copper powder, DM Cu, for use with its binder jet 3D printing technology.

Users of the DM P2500 3D printer will now be able to 3D print 99.9% pure copper components on the shop floor. The material is known for its excellent thermal conductivity, making it the universal choice for heat transfer components such as heat exchangers, piping, and heat sinks for engines and electronics.

Owing to its ductility and electrical conductivity, pure copper also sees extensive use in the production of electrical connections such as wiring. As a bonus, copper also exhibits antibacterial properties, opening up new avenues for the 3D printing of medical devices, although this is a much less common application.

Christian Lönne, CEO at Digital Metal, states, “Printing with pure copper using Digital Metal’s binder jetting technology is one of the most anticipated material launches ever, and totally new within binder jetting. Copper has been high up on our customers’ wish list and timing is perfect with the demand for copper applications soaring in fast growth areas such as e-mobility and heat conductivity.”

Horn antennas and heat sinks

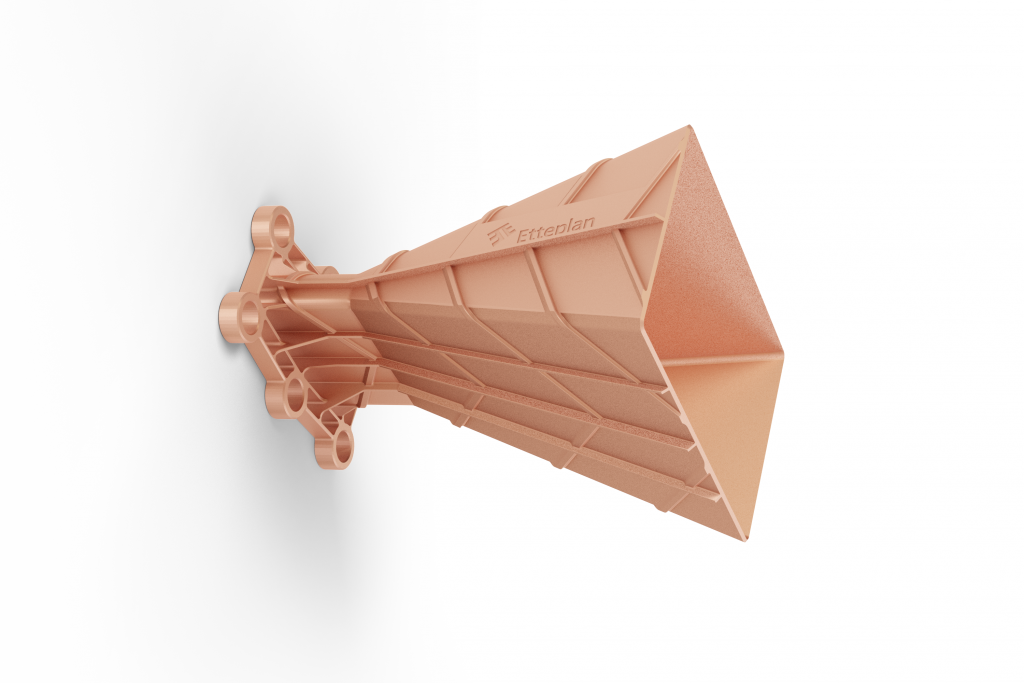

Digital Metal has already experimented with its new DM Cu powder via a number of test applications in-house. Firstly, the company 3D printed a horn waveguide antenna, which is used to direct radio waves in a beam.

Components like the horn antenna are usually quite costly to manufacture when using conventional techniques, and may only be needed in low-volume for specialized research or aerospace projects. As such, the cost-per-part can skyrocket – a problem Digital Metal can solve with its 3D printing technology. The use of binder jetting here also lends itself to weight savings, as the company’s engineers were able to opt for a lightweight thin-walled structure with ribs to add the necessary stiffness.

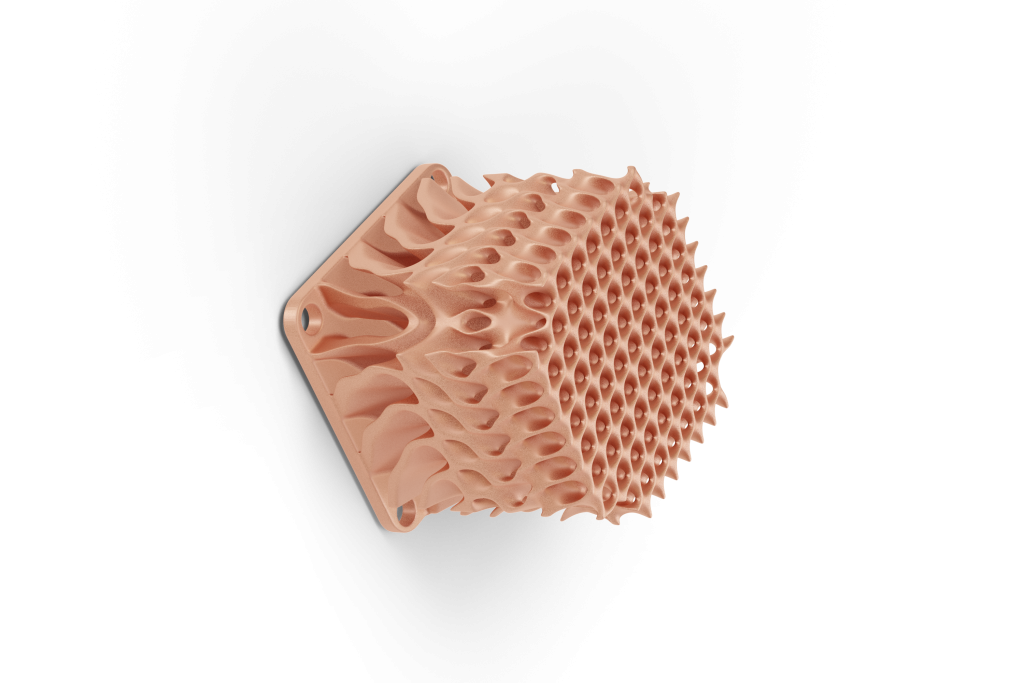

The company also 3D printed a Triply Periodic Minimal Surface (TPMS) heat sink with a gyroid geometry (one that resembles nTopology’s). Gyroid heat sinks offer increases in both heat transfer rates and rigidities when compared to plate and pin fin designs, and are only manufacturable via 3D printing. In Digital Metal’s heat sink, the TPMS structure was modified with thick walls at the base and thin walls at the top, encouraging a stronger convective flow.

Lönne added, “We have been developing the process for some time internally, but I would really like to emphasize the value of the excellent cooperation with key customers in our fast-growing Digital Metal User Group. It has been a great help and we are now very pleased to deliver a high-quality copper process for Digital Metal binder jetting.”

The Digital Metal materials portfolio

The addition of DM Cu has further strengthened Digital Metal’s extensive powder portfolio, which can be attributed to parent company Höganäs AB, a leading manufacturer of metal powders. Other materials in the range include superalloys DM 625 (equivalent to Inconel 625) and DM 247 (equivalent to MAR M247). Intended for use in ‘extreme applications’, the powders exhibit excellent mechanical properties, corrosion resistance, and heat stability.

More recently, the company launched its proprietary DM D2 tool steel alloy, a high-carbon, high-chromium steel that can be fully heat treated to feature excellent hardness and compressive strength. The material delivers both abrasive wear resistance and toughness, making it a great choice for manufacturing tooling applications.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows pure copper parts 3D printed by Digital Metal. Photo via Digital Metal.