Antimicrobial material developer, Copper3D, has developed a new 3D printed device to be used during breastfeeding. The device, made of Copper3D’s trademarked PLACTIVE material, aims to act as an interface between mother and child during breastfeeding, inactivating HIV found in breastmilk.

The novel material uses nano-copper based additives to give standard PLA antimicrobial properties. Previous studies have already proven the potency of the material, prompting Copper3D to develop an end-use model to be used outside of the laboratory.

The HIV problem

According to the WHO, 37.9 million people were living with HIV in the world at the end of 2018. 8.1 million of these people didn’t know they had the disease. In 2017, the number of children and adolescents living with HIV reached 3 million, with 430,000 newly infected and 130,000 died from AIDS-related causes that year, according to UNICEF. During 2018, 26,000 new HIV infections among children aged 0-14 years, were the results of withdrawal of treatment during pregnancy and because of breastfeeding, according to UNAIDS.

Breastfeeding is a key mode of HIV transmission in developing countries where inactivation drugs and adequate education are not present. To control and minimize breastfeeding transmission would significantly cut HIV rates in young children who would otherwise have no choice but to be exposed to the virus.

Dr. Claudio Soto, Medical Director of Copper3D, stated: “Understanding the global problem behind the HIV statistics and analyzing the role that our antimicrobial materials could have in containing the transmission of HIV virus led us think that we could develop some kind of device that acts like an interface between mother and child to prevent the spread of this virus through breastfeeding, which is one of the main routes of infection.”

PLACTIVE versus HIV

Copper-based additives and filters inactivate HIV by acting specifically against protease, which is essential for replication. Copper ions degrade the virus phospholipid plasmatic membrane and denaturalize the nucleic acids of the virus. This has the potential to slow down virus growth significantly but it does come with its challenges. Breast Milk infused with copper ions has currently unknown toxicity levels, the nutritional degradation of the milk is unknown, and the required contact time between the virus and PLACTIVE for significant inactivation is currently being studied.

To solve these issues, the Copper3D team initiated two lines of research for the project. The first part of the project was focused on determining just how effective PLACTIVE was against samples of HIV infected breast milk. The second part was focused on designing an object that could act as a mother to child interface and optimize the viral inactivation of HIV in contaminated breast milk.

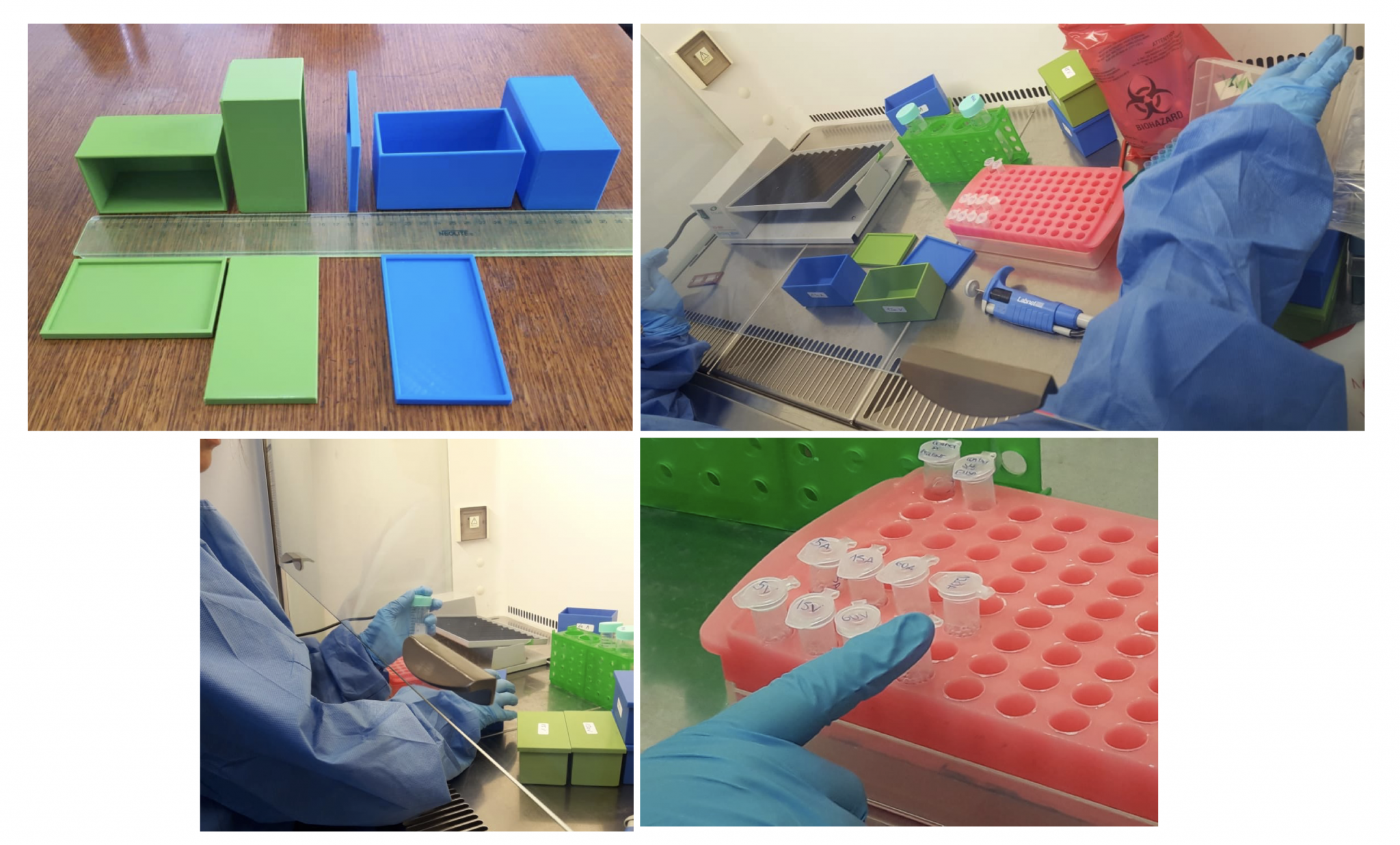

The laboratory process

The Copper3D team commissioned a laboratory study that involved a simple blind, randomized and positive/negative control group. Twenty samples of HIV-1 were treated and randomized into A, B and control groups. A and B samples were placed in 3D printed PLACTIVE boxes with surface areas of 40 square cm. The samples were exposed for 15, 60, 120 and 900 seconds to the PLACTIVE surfaces.

Daniel Martínez, Director of Innovation of Copper3D, explained: “The preliminary results showed a reduction of viral replication up to of 58.6% by simply exposition of the samples to the 3D printed boxes containing copper nanoparticles. Fifteen seconds of exposition were enough to achieve such a reduction. These data allow us to infer that by increasing the contact surface by a factor of 10X, we could obtain much higher inactivation rates, very close to 100% and according to our calculations, most probably in less than 5 seconds.”

According to Copper3D, the project was the first of its kind to study the inactivation of HIV by using polymers with antimicrobial copper nanotechnology through 3D printing. The success of the experiment led to the design of the HIV inactivating end-use device.

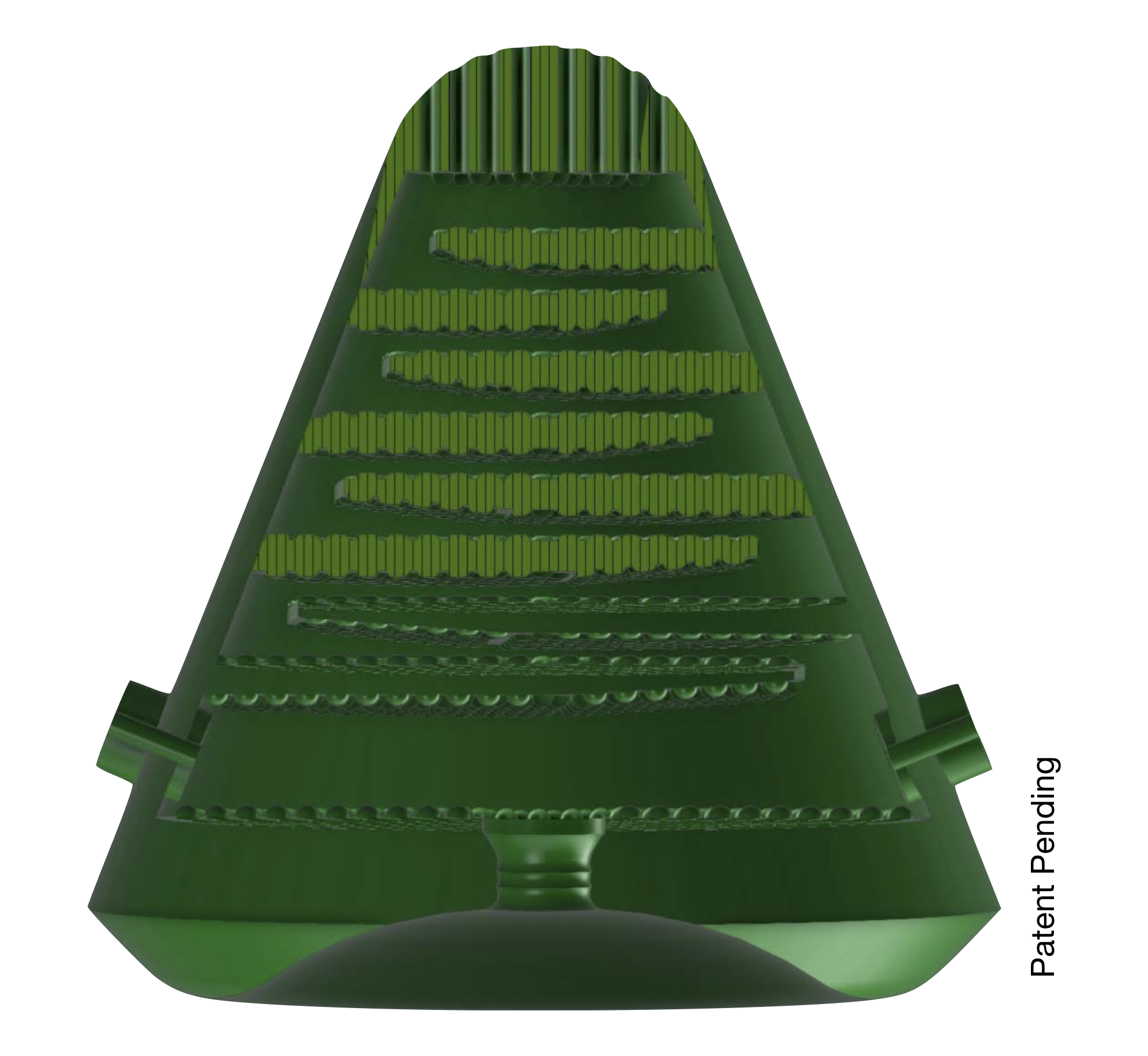

The viral inactivation device

The device relies on the proven antimicrobial capabilities of nano-copper materials. By maximizing the surface area and time the infected milk is in contact with the PLACTIVE, HIV inactivation can be maximized, to the point where it is no longer infectious to the breastfed child. The device aims to expand the contact area by a factor of around 10X, using a layered design emulating the structure of the gastrointestinal tract. The team aims to have a finalized, fully functional model sometime in 2020.

Jorge Zuniga Ph.D., Associate Professor of Biomechanics at the University of Nebraska, says “Copper3D has once again disrupted the field of medical devices by creating this revolutionary device that can have a tremendous impact in reducing mother-to-child transmission of HIV. Our laboratory is fortunate to partner with Copper3D, in such an impactful project”.

Copper3D is not the only company to develop antimicrobial 3D printing materials. STERNE, a French silicone manufacturer, has previously released an antimicrobial silicone that resists the formation of bacteria both in and outside of a 3D printed product. Elsewhere, in Greece, researchers have developed antimicrobial 3D printable wound dressings with healing capabilities. With the emergence of new viruses, perhaps the exploration of 3D printing solutions in years to come could yield significant results in the field of epidemiology.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows PLACTIVE medical tools. Photo via Copper3D.