STERNE, an industrial silicone manufacturer headquartered in the Provence-Alpes-Côte d’Azur region of southern France, has launched a new material for 3D printing. Made for use with the company’s SiO-Shaping system, the new release is an antimicrobial silicone that resists the formation of bacteria both in and outside of a 3D printed product.

The material, to be presented at world plastics and rubber trade fair K2019 next week, builds on a 3D printing portfolio that the company has been growing since 2016.

STERNE SiO-Shaping

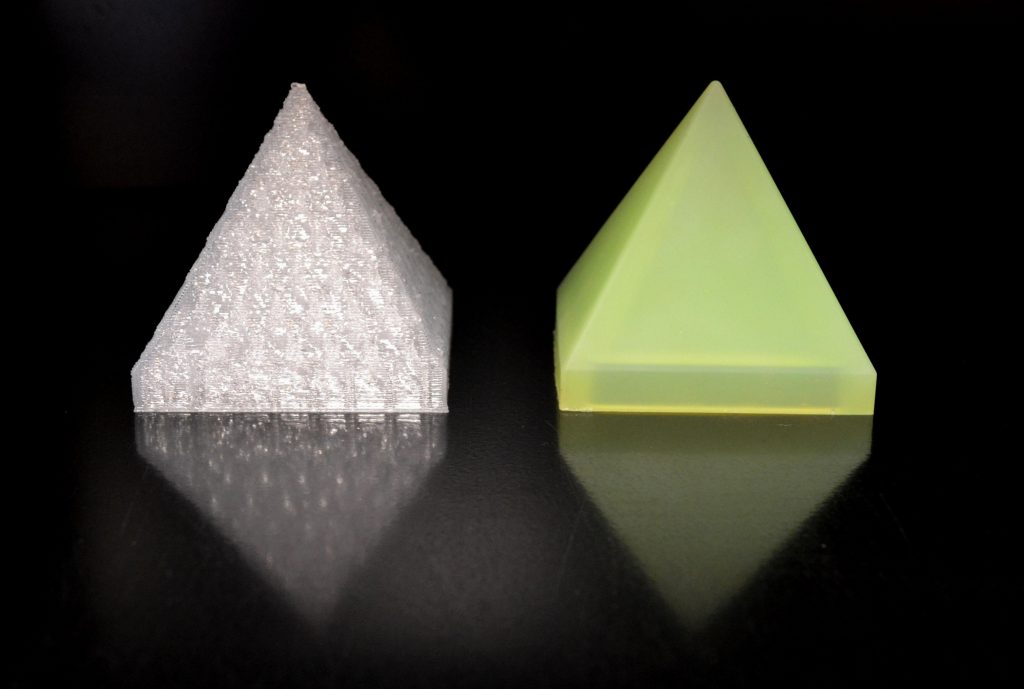

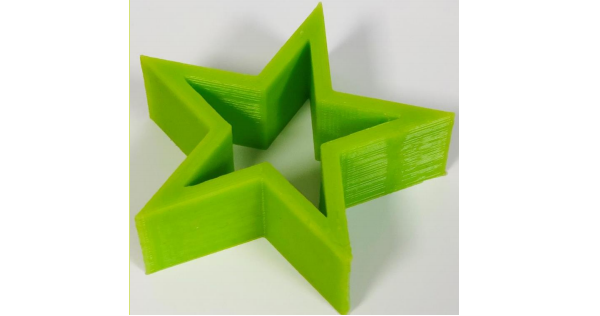

SiO-Shaping is STERNE’s 3D silicone printing platform. It combines FFF deposition technology with UV curing, and uses filaments of silicone feedstock.

The first version of the SiO-Shaping 3D printer, the SiO-Shaping 1601, was presented publicly by the company in 2016. Over the following 18 months the system was refined by STERNE to produce 3D printed prototypes with resistance and elongation properties identical to the final injection-molded product. In its current iteration, the SiO-Shaping 1601 3D printer is capable of depositing material down to a minimum layer thickness of 0.1mm (100μm). Maximum print dimensions are 205mm x 200mm x 100mm (L x W x H), and the system can work with materials between 30 and 60 Shore A hardness.

Materials supplied by STERNE for use with the SiO-Shaping platform come in a range of different colors, each meeting quality requirements of either the FDA or USP Class VI medical designation. By resisting the formation of bacteria, antimicrobial 3D silicone from STERNE has an improved hygiene rating, also avoiding the impregnation of odors. With this material, product developers can accurately test small batches of prototypes before they reach the market.

The up-and-coming 3D printed silicones market

Working in silicone STERNE operates as part of a small, yet developing, niche of the 3D printing industry.

International chemical group WACKER is possibly the best-known providers of 3D printed silicone services and materials. Marketed under the ACEO brand, WACKER’s 3D printed silicone division recently expanded with the foundation of a million dollar Open Print Lab in Ann Arbor, Michigan.

Elsewhere, Swiss silicone 3D printing service Spectroplast AG entered the market with €1.38 million in backing from a seed round led by AM Ventures. In a Q&A with Spectroplast Co-Founder and CEO Petar Stefanov, 3D Printing Industry learned more about the demand for this technology within the current market.

Most recently, 3D printer manufacturer German RepRap entered the fray with its Liquid Additive Manufacturing (LAM) system that can be used to process 3D printing liquid silicone rubber.

For more of the latest 3D printing materials releases subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows 3D printed silicone (left) vs an injection molded silicone pyramid (right) from STERNE. Photo via STERNE