On-demand digital manufacturing provider Protolabs has launched a new polypropylene (PP) 3D printing service for its customers in Europe. A company first, the Telford-based Northern European branch of Protolabs has invested significantly in development of the material for SLS 3D printing. “Until recently you could only use 3D printed polypropylene-like materials that mimicked this plastic, but they did not have all of the same properties and were not as durable,” explains Andrea Landoni, 3D printing product manager for Protolabs.

With the launch of the new service the company aims to provide design engineers with the ability to develop and test prototypes using the same material as used for production. SLS technology will also enable the creation of complex designs that can’t be achieved with traditional manufacturing technologies.

“The product design can […] be quickly reiterated and retested until [designers] have the perfect solution, before committing to tooling,” adds Landoni.

“This breakthrough takes product development to the next level using the most versatile of plastics.”

The many applications and uses of polypropylene plastic

Polypropylene is a low-temperature thermoplastic (130°C-171°C) produced through the polymerization of propylene, a colorless hydrocarbon gas. It is the second most widely produced commodity plastic in the world, after polyethylene.

The material has a semi-crystalline molecular structure, which prevents it from softening until a given quantity of heat is fully absorbed. PP is therefore highly resistant to heat, despite having a low melting temperature. It is also highly flexible, with a tensile strength of 1.9 GPa, and offers resistance against electricity and a number of chemicals, including dilute acids, dilute alkalis, and alcohols.

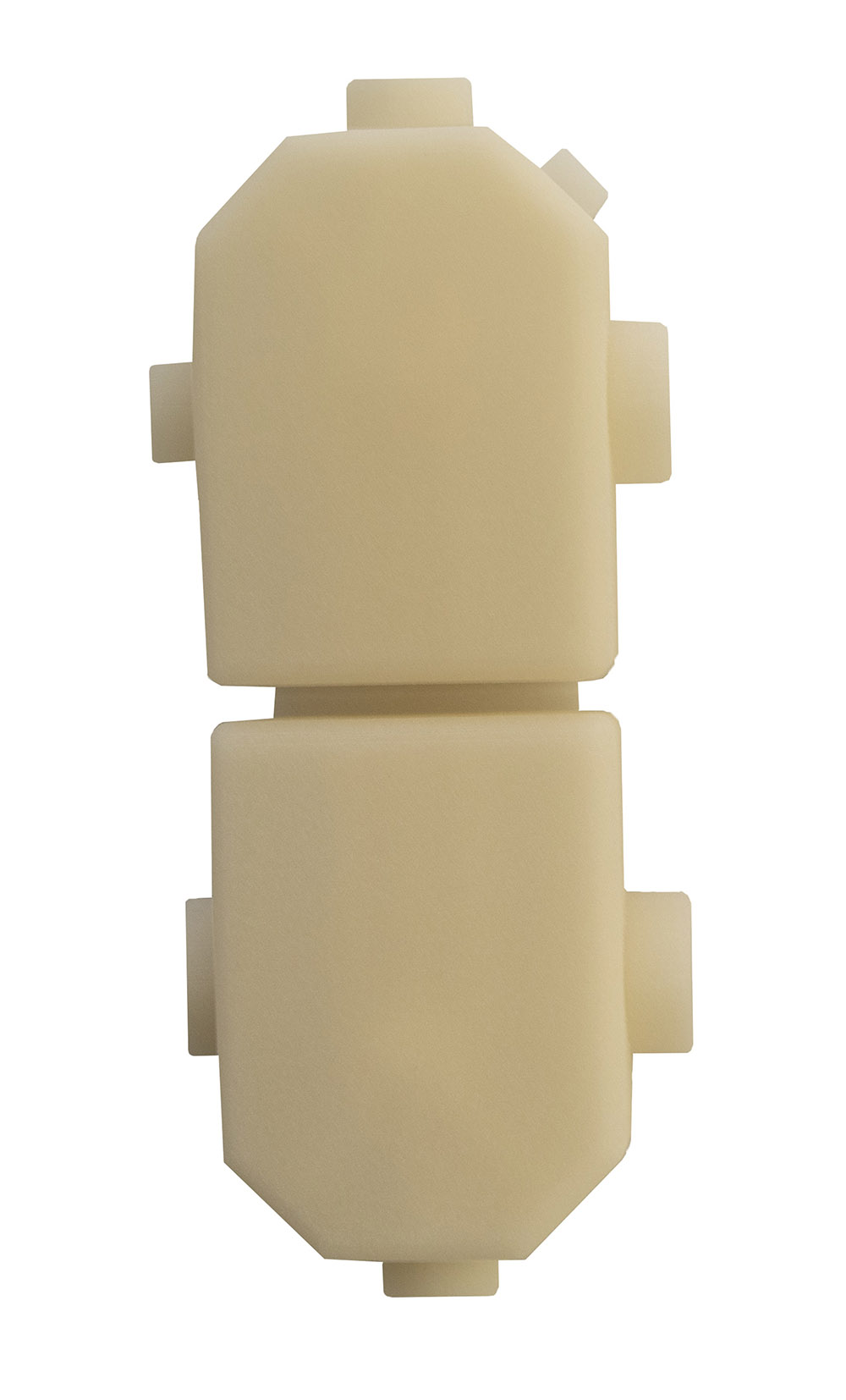

These combined properties make the material suitable for a number of applications, like packaging, living hinges, and electrical insulators, hence its common usage. Typically, PP is used when injection molding products. However the material has been picked up by other 3D printer manufacturers like Germany’s Apium Additive Technologies and French industrial 3D printer provider Prodways.

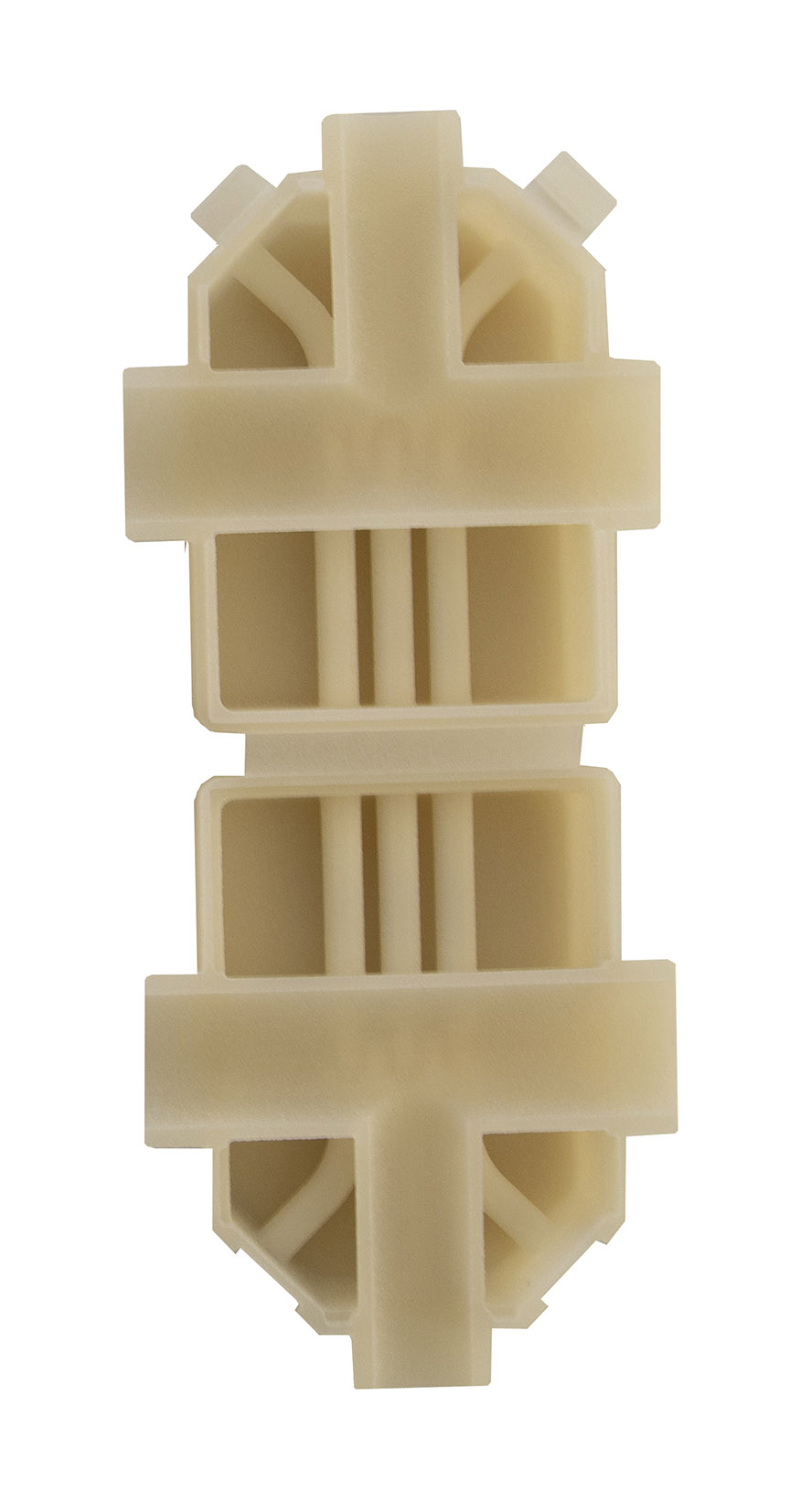

When processed through 3D printing, PP applications opens up to host of designs with complex geometries that can’t be achieved with injection molding. This includes the design and production of honeycomb structures to reduce weight or organic shapes such as internal channels.

Protolabs offers CNC machining and injection molding services for manufacturing parts with PP as well as the new 3D printing service. Remaining technology agnostic, the company will therefore be able to advise its customers on which manufacturing technology suits their application. “Before, if you wanted to use polypropylene then you were limited in what you could design by the manufacturing technology available to you,” continues Landoni, “Now the only limitation is your imagination,”

Protolabs expanding its 3D printing material portfolio

With the launch of its new SLS PP service, Protolabs continues to expand its on-demand 3D printing capabilities. Recently the company announced the addition of Carbon’s Digital Light Synthesis (DLS) to its portfolio. This includes use of RPU and FPU materials from Carbon, comparable to ABS and polycarbonate.

Shifting out of prototyping to meet the requirements of more customers seeking end-use 3D printed parts, the company also launched its high requirements direct metal laser sintering service in June this year. The move was further discussed by Protolabs CEO Vicki Holt in for 3D Printing Industry exclusive interview.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed polypropylene housing with living hinge. Photo via Protolabs.