Biogelx, a Scottish biomaterial developer, has launched an international distribution strategy for its 3D printable inks. Working with 3D Biotechnology Solutions (3DBS), a startup specializing in custom bioprinter and electrospinning machines, the company has set its sights on the Brazilian medical sector.

According to Sandy Bulloch, Director of Strategic Alliances at Biogelx, this new partnership will be leveraged to help scale the business and “provide a complete bioprinting platform for multiple cell culture applications.”

“This collaboration,” Bulloch adds, “will accelerate the pace of our bioprinting innovation to generate the next generation of 3D tissue models.”

Biogelx 3D printable hydrogels

Spun out of Scotland’s University of Strathclyde in 2013, Biogelx is a specialist producer of synthetic hydrogels used to make 3D cell scaffolds. The company’s core technology is the BiogelxTM self-assembling peptide hydrogel – a range of materials specially formulated to support the growth and proliferation of different cell lines. The line was developed by the company as a viable alternative to animal-derived matrices such as collagen and Matrigel. Expanding on this range earlier in 2019, Biogelx now also offers a range of materials suitable for 3D bioprinting. This product line is termed Biogelx™-INKs.

Biogelx™-INKs are currently available in three different formulations from the company – one a standard hydrogel, and two functionalized either by fibronectin (a major component of the extracellular matrix and blood plasma) or collagen (the structural protein of skin and connective tissues).

An international contribution to regenerative medicine

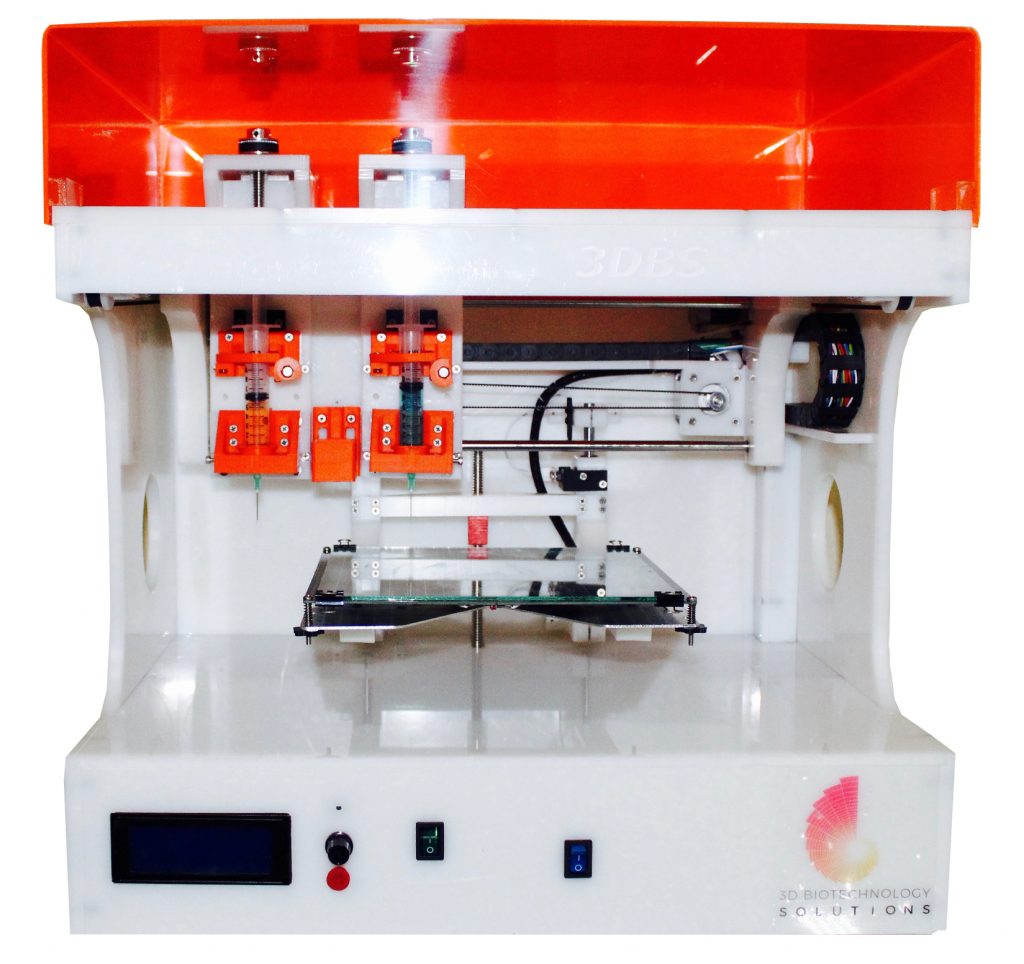

Working in the field of tissue engineering, 3DBS produces a range of custom-made 3D bioprinters for use in a laboratory setting. The company was founded in 2017, yet already offers six products in its 3D bioprinter line. One standard model is the Genesis I system, which enables the independent control of two syringe-extruders at temperatures between 25-220 °C.

The vision of 3DBS, according to co-founder Pedro Massaguer, “is to be a significant contributor in the construction of the future of regenerative medicine.” By partnering with Biogelx, 3DBS adds the range of Biogelx™-INKs materials to its distribution in Brazil, offering customers a more complete package for conducting biological research.

“By enabling customers to work with Biogelx™-INKs using our bioprinters such as Genesis™, Reactor™ or Octopus™, we are getting one step closer to our revolutionary goal,” Massaguer adds.

“Together, we have the opportunity to deliver more tissue-specific like constructs for applications in regenerative medicine and drug discovery.”

For more of the latest medical and material updates subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows a sample of 3D printed Biogelx™-INK. Photo via Biogelx