Bristol University has produced a bio-ink that prints stem cells that develop into complex tissues like bone and cartilage. So true bioprinting is one step closer now.

At the moment, bioprinting is very much in the experimental stage and we still rely on the likes of titanium for knee and hip replacements. Bioglass, meanwhile, is showing great potential as a cartilage replacement and natural scaffold. Fully compatible bio-printed replacements would be infinitely better, however, and this development in the UK is seriously good news.

Seaweed is a magic ingredient

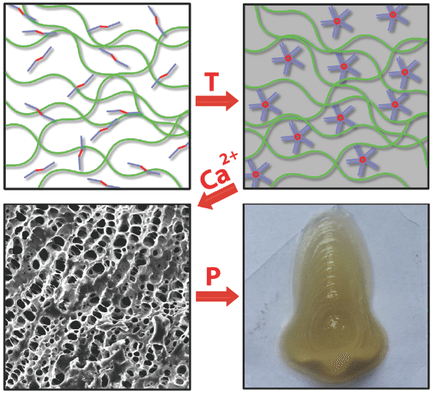

This new bio-ink is created by using two polymers, one of which is extracted from seaweed. That acts as the scaffold and it reacts with a synthetic polymer that causes the solidification of the ink when the temperature is raised.

“Designing the new bio-ink was extremely challenging,” said lead researcher Adam Perriman, from the School of Cellular and Molecular Medicine at Bristol University. “You need a material that is printable, strong enough to maintain its shape when immersed in nutrients, and that is not harmful to the cells. We managed to do this, but there was a lot of trial and error before we cracked the final formulation.”

Hacking a desktop printer to make medical history

One of the more impressive things about this whole venture is that Bristol University, like Carnegie MellonUniversity and others before it, simply hacked a desktop 3D printer to produce a machine that could change life as we know it.

The printer operates with a layer by layer approach and the ink is deposited and heated simultaneously. The team created a shaped gel structure that can be used to grow the cell cultures. It then embedded stem cells before differentiating them into osteoblasts and chondrocytes, which are the basic building blocks of bone and cartilage.

“What was really astonishing for us was when the cell nutrients were introduced, the synthetic polymer was completely expelled from the 3D structure. That left only the stem cells and the natural seaweed polymer,” Perriman said. “This, in turn, created microscopic pores in the structure, which provided more effective nutrient access for the stem cells.”

This research was published in the journal of Advanced Healthcare Materials and it’s clearly a major step forward for the whole medical profession.

Big breakthroughs are coming

So many major institutions have focused on bone and cartilage replacements of late that the major breakthrough is a matter of when, not if. In Milan a group of scientists have found a way to create viable cartilage replacements from bioglass, a material that has been with us since the late 1960s. But that could be rendered totally redundant by this study.

This research is much wider reaching, too, because if we can truly master stem cells then there is no limit to what we can do.

The sheer potential of producing implants, cartilage and even organs from our own stem cells is breathtaking. We would no longer need to wait for donors, there would be no problem with compatibility and that means that transplant surgery would be much less stressful for the patient. They currently have to cope with a vast amount of drugs to prevent the body rejecting the new organ and that is an ordeal in itself.

Organs will be like spare parts: printable on demand

If we can grow organs like spare parts and we know in advance they are a perfect match, then it will bring blessed relief to millions of people around the world and help change the face of medicine.

Even cartilage would be a blessing, as we simply cannot replace it as things stand and there are huge numbers of people struggling with crippling conditions related to the cartilage wearing away. If we can reverse the aging process and give them replacement cartilage grown from their own cells, then that alone is a medical miracle.