Researchers at Brigham and Women’s Hospital (BWH) have successfully 3D bioprinted tubular structures which imitate the human body’s vessels.

According to BWH’s report, the 3D bioprinting technique allows for better replications of the tissues’ properties, such as the number of layers and ability to transport nutrients. These bioprinted tissues could potentially offer a viable solution for damaged tissue.

“The vessels in the body are not uniform.” stated Yu Shrike Zhang, Ph.D. and senior author on the study. “This bioprinting method generates complex tubular structures that mimic those in the human system with higher fidelity than previous techniques.”

3D bioprinted tubes

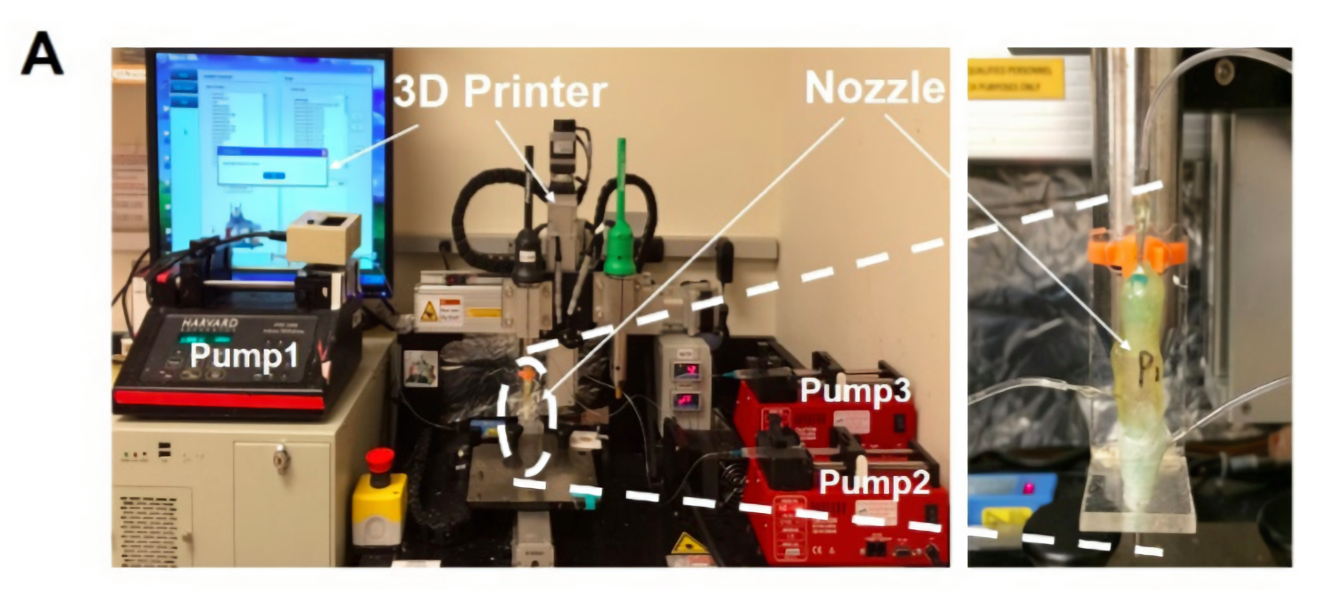

In order to 3D bioprint the tissue, a special “bio-ink” is made by mixing human cells with a hydrogel, a flexible structure composed of hydrophilic polymers. Researchers then optimize the polymer to allow the human cells to proliferate in the mixture, after which, the “bio-ink” is then placed into a 3D bioprinter cartridge.

Finally, the 3D bioprinter is fitted with a custom nozzle that allows it to continuously print tubular structures with up to three layers.

The printed tubes have various sizes, thicknesses and properties. According to Zhang, structural complexity of bioprinted tissue is important for it to be a viable replacement for native tissues, which are naturally complex. For example, blood vessels are comprised of multiple layers, as well as various types of cells.

Several disorders can lead to tubular tissue damage, such as arteritis, atherosclerosis and thrombosis. With BWH’s new technique, doctors could potentially replace damaged, complex tissue in vents and ducts that are used to transport nutrients in the body.

Advancements in 3D bioprinting

This study expands on Ali Khademhosseini’s work at the University of California, Los Angeles (UCLA) in collaboration with Zhang at BWH, where his team developed a way to bioprint multiple materials in one process on microfluidic chip. BWH is also collaborating with the Wake Forest Institute for Regenerative Medicine (WFIRM) to build a full, 3D printing body-on-a-chip.

As the advantages and capabilities of 3D bioprinting grow, other organizations have started researching new 3D bioprinting techniques. The University of Oxford spinout company, OxSyBio, received £10 million for further development of 3D bioprinting technology. Oxford also partnered with the University of Bristol to develop 3D bioprinted tissues that match the behaviour and structure of those in the human body.

3D bioprinting blood vessels is challenging because not only are they incredibly small and tubular, but they are made up of multiple kinds of cells and layers.

“We’re currently optimizing the parameters and biomaterial even further,” said Zhang. “Our goal is to create tubular structures with enough mechanical stability to sustain themselves in the body.”

“Digitally Tunable Microfluidic Bioprinting of Multilayered Cannular Tissues” is published in Advanced Materials journal. It is co-authored by Qingmeng Pi, Sushila Maharjan, Xiang Yan, Xiao Liu, Bijay Singh, Anne Metje van Genderen, Felipe Robledo‐Padilla, Roberto Parra‐Saldivar, Ning Hu, Weitao Jia, Changliang Xu, Jian Kang, Shabir Hassan, Haibo Cheng, Xu Hou, Ali Khademhosseini, and Yu Shrike Zhang.

For more 3D bioprinting updates and general 3D medical news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Seeking new professional opportunities? Search and post 3D Printing Jobs now.

Featured image shows the biocompatibility of BWH’s 3D printed tissue. Photo via Advance Materials.