Addressing volume limitations within additive manufacturing and construction, roboticists from the Nanyang Technological University (NTU) in Singapore have created a method for large-scale concrete 3D printing using multiple synchronized mobile robots.

As the study states, “The biggest limitation of printing systems is their lack of scalability,”

“Our system demonstrates scalability by allowing users to introduce as many robots as needed in a shared environment for task completion in a fast and efficient manner.”

Breaking down the walls of 3D printing in construction

From the gantry-based cement 3D printer of the Army’s Construction Engineering Research Laboratory (CERL), to BatiPrint3D’s first habitable 3D printed home, large-scale 3D printing systems are gradually proving their worth in construction.

Nevertheless, restrictions remain. Chamber volume sizes (particularly within gantry-based 3D printing systems) continue to dictate a building’s size and design. Furthermore, structures printed using stationary robotic arms may require on-site assembly which requires additional design consideration.

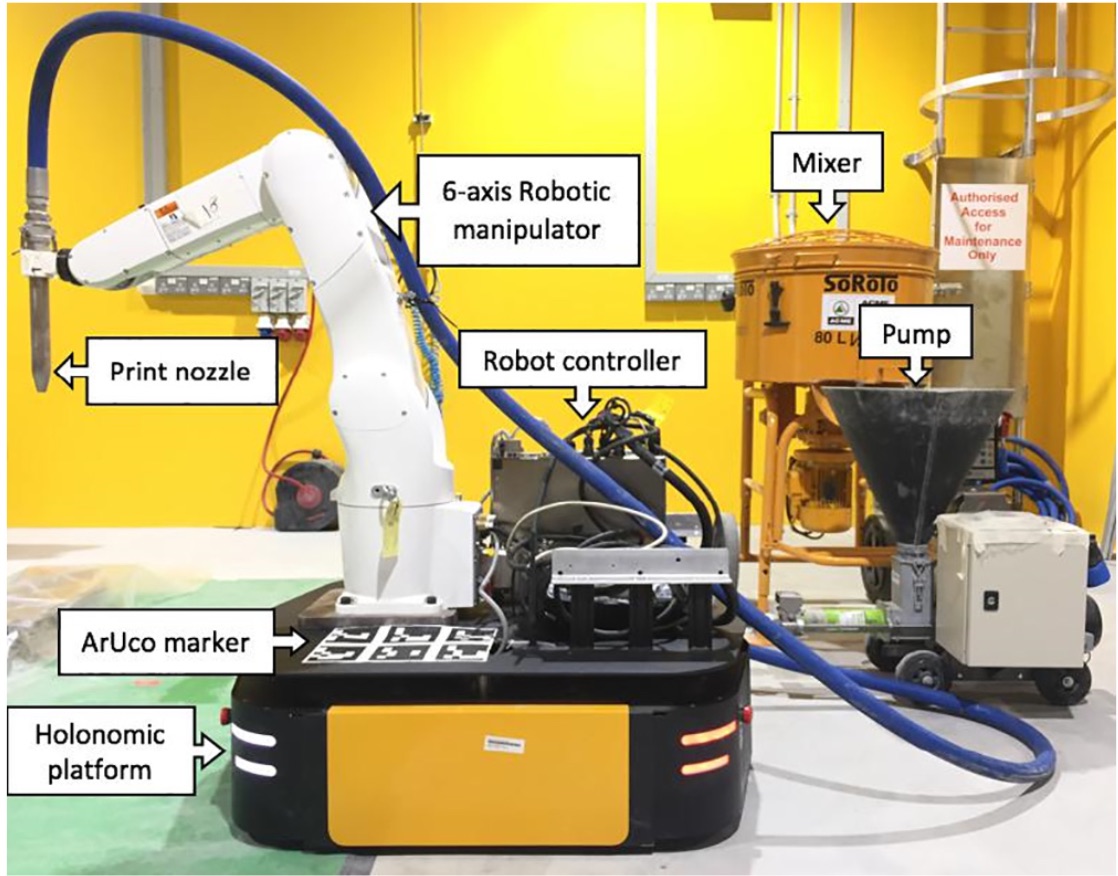

The NTU roboticists have created a moving robotic concrete 3D printing system to overcome these constraints. This system includes a 6-axis robotic manipulator equipped with a single printing nozzle based on an interconnected (holonomic) mobile platform which uses sensors for localization. A pump system is also integrated into the robot to supply it with construction material.

The robotic mobile printing systems are guided by an array of cameras and ArUco markers – wide black borders placed on a flat surface to control the robots’ boundaries.

Robot-cement collaboration

According to the NTU roboticists, with multiple robot printers, each one is able to tackle a different part of a structure at the same time, without the need for significant changes in the robot’s system. As well as shortening the overall time used to print, this method is said to fabricate stronger, more complex structures, as post-bonding is not necessary.

The NTU team believe that fleets of these robots can be used within “automated construction in hard-to-reach, remote areas, such as underground caves, the Moon or Mars, to which it is inconvenient or even impossible.”

The robots are still under development as the NTU team work to add mobility to the robots during the actual 3D printing process, in addition to the robots localization phase. Furthermore, the team is working to expand each robot’s reach which currently stands at 0.9m with a repeatability of 0.02mm.

The research paper “Large-scale 3D Printing by a Team of Mobile Robots,” is co-authored by Xu Zhang, Mingyang Li, Jian Hui Lim, Yiwei Weng, Yi Wei Daniel Tay, Hung Pham, and Quang-Cuong Pham from the Nanyang Technological University in Singapore.

For more of the latest 3D printing news subscribe to the 3D Printing Industry newsletter and follow us on Twitter, and Facebook.

Also, search and post 3D Printing Jobs to seek opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the mobile robots cooperating to 3D print large concrete structures. Clip via NTU.