The Ramdani family has become the world’s first inhabitants of a 3D printed four-bedroom house located in Nantes, France.

This house is part of the social housing project, Yhnova, which aims to construct affordable, adaptable, and energy efficient housing in a time and cost-effective manner.

Led by the University of Nantes (IUT), the Yhnova project was completed under a consortium of scientists, manufacturers, and public and socio-economic actors who are now planning to create a suburban neighborhood using the same building principles.

The success of project Yhnova

Last year, the Yhnova project began breaking ground in a deprived neighbourhood in the north of the Nantes to prepare for the construction of the 3D printed house. IUT Professor and Project Manager, Benoit Furet’s concept for this house was to fully realise an architect’s vision using innovative and disruptive manufacturing technology.

“The advantage of 3D printing is that it enables us to have far richer solutions in terms of the shape of the house. It’s much more interesting to architects than the traditional building of straight walls.”

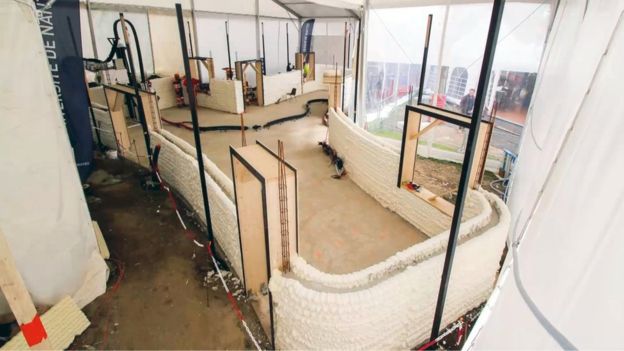

With the freedom allowed by their patented 3D printing technology, BatiPrint3D, the arched walls designs were able to improve thermal resistance, air circulation, and create a wheelchair accessible layout within the house. The 3D printed house was also built to curve around 100-year-old protected trees on the plot.

Overall the 95 metre house took 54 hours to print, excluding the four months taken for contractors to fit windows, doors and roof fixtures. The building cost of the house totalled an estimated £176,000, which is 20% cheaper than an identical construction with traditional methods.

“It’s a big honour to be a part of this project,” stated Nordine and Nouria Ramdani, the chosen family that will be living in the 3D printed house along with their three children.

“We lived in a block of council flats from the 60s, so it’s a big change for us. It’s really something amazing to be able to live in a place where there is a garden, and to have a detached house.”

The Batiprint3D process

3D printing for construction and building continues to be used in various ways to create unique houses and structures. Construction companies are using methods that directly deposit cement onto the desired foundation to create building structures, as seen with Contour Crafting. However, the BatiPrint3D method, developed by researchers at IUT, prints parallel layers of insulator polyurethane that is then filled in the middle with cement.

The robotic arm constructs the thick, insulated, and fully-durable walls in the predetermined shape for the house.

A 3D printed suburban neighbourhood

With the successful completion of the Yhnova project, Professor Furet is now planning to 3D print 18 houses in the north of Paris to further improve the social housing conditions of residents within the area.

“Social housing is something that touches me personally,” said Professor Furet. “I was born in a working-class town and lived in a little house. My parents – who are very old now – still live in the same house [where] the street is a row of little houses, one next to the other, all identical.”

Due to the advancements in their BatiPrint3D technology, Professor Furet also believes that his team can reduce the cost of the construction of such houses by 25% in five years and by 40% in 10 to 15 years. Franky Trichet, the Deputy Mayor of the City of Nantes has confidence in the application of this technology for the economical future of French cities.

“The future of the project from the perspective of the town is two-fold. The first is to see whether we can mainstream this type of construction. The second objective for us is to see if we can apply these construction principles for other types of public buildings – like sports halls or communal buildings.”

The team now believe they could print the same house again in 33 hours.

Keep up with the latest in 3D printing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Need a change of pace? Seeking new talent for your business? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the 3D printed house in Nantes. Photo via BBC.