In addition to university labs, Hyrel 3D has been one of the original pioneers of paste extrusion for 3D printing. Long before the Discov3ry extruder from Structur3D, Hyrel was 3D printing with Play-Doh, clay, and Sugru. Now, the Georgia-based company has announced an entirely new line of extruders that launches Hyrel from desktop engineering into the world of desktop bioengineering.

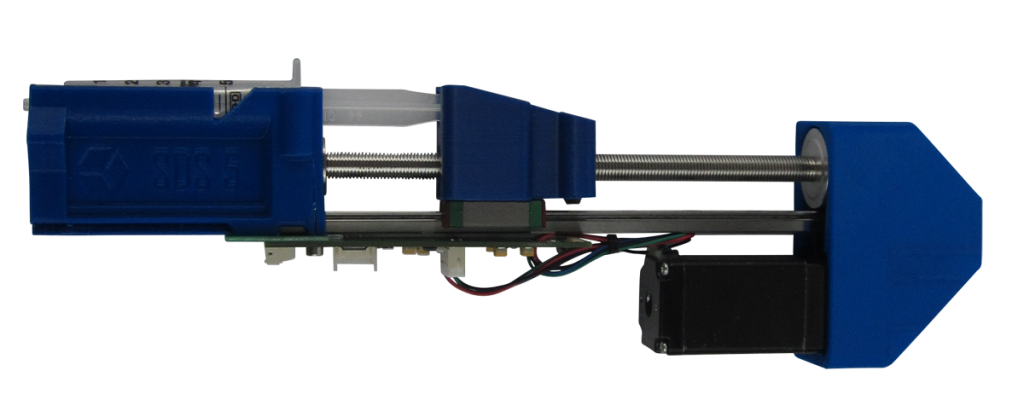

Working with “research teams on five continents”, Hyrel has developed the Syringe Delivery System (SDS) line of extruders, designed to allow users to 3D print using easily filled, swapped, and stored syringes. The SDS line, which supports syringes from 100 microliters to 60cc in size, is mean to handle any material that can be extruded from a syringe, including the possibility to mix and match materials. This “means the end of monopolies on material supply chains by 3D printing companies,” according to the company. While this may open up material printing possibilities, the SDS line is designed only for Hyrel 3D printers, such as the Hyrel System 30M, for layered and gradient 3D prints.

Each extruder, starting at $400 for a basic single print head, is manipulated locally with a Canbus, used to network the extruder, and a MicroController. A quad-extrusion print head, which can operate with micro-fluidic mixing chips, starts at $2,500. With the ability to achieve nano-liter resolution, Hyrel lists example materials for the SDS line as including: “bio-gels and liquids used for bioplotting; proteins, steroids, and PEG gels; RGB materials; [and] conductive pastes and liquids.” Hyrel Chief Technology Office Karl Gifford says of the new line, “The SDS opens up the unrestricted sourcing of chemicals for 3D printing — you’re no longer restricted to what suppliers will sell you. It’s ideal for people that want to develop cost-effective applications in numerous fields.”

For $5,000, including an MK1-250 extruder and filament, the System 30M is more affordable than high-end bioprinters. At the same time, it sounds as though this system may be more flexible than the low-cost printers on the market, like the INKREDIBLE from CELLINK and the BioBot1 from BioBots. And, as these extruders can be networked together, they may have more industrial applications than the Discov3ry extruder. So, though the SDS line can only be used with Hyrel’s own printers, it may open up a new range of materials and applications to those looking to print with viscous matter.