3D printing software developer Authentise and data visualization and analytics provider nebumind have received a grant from the European Union (EU) to further their 3D printing software and workflow partnership.

Announced in November last year, the project involves integrating nebumind’s digital twin visualizations with Authentise’s AMES workflow management software in order to improve analytics, processing time and costs, and automated quality reporting within 3D printing.

The partnership is funded by the EU’s Horizon 2020 research and innovation program through Digifed, the Digital Innovation Hubs Federation for large-scale adoption of digital technologies by European businesses.

“The support is incredibly meaningful not only to our joint ability to execute as planned but to the market in general,” said Caroline Albert, co-CEO at nebumind. “Enabling integration of digital solutions such as nebumind and Authentise in this way boosts the value to industrial customers who are already overwhelmed with a plethora of different tools and reduces the reliance on solutions sourced from single vendors.”

Authentise and nebumind’s partnership

Authentise and nebumind first announced their partnership in November 2020 with the goal of helping users more easily identify problem zones of 3D printed parts to make inspections more accurate and less time-intensive, and provide users with improved and actionable insights into part data.

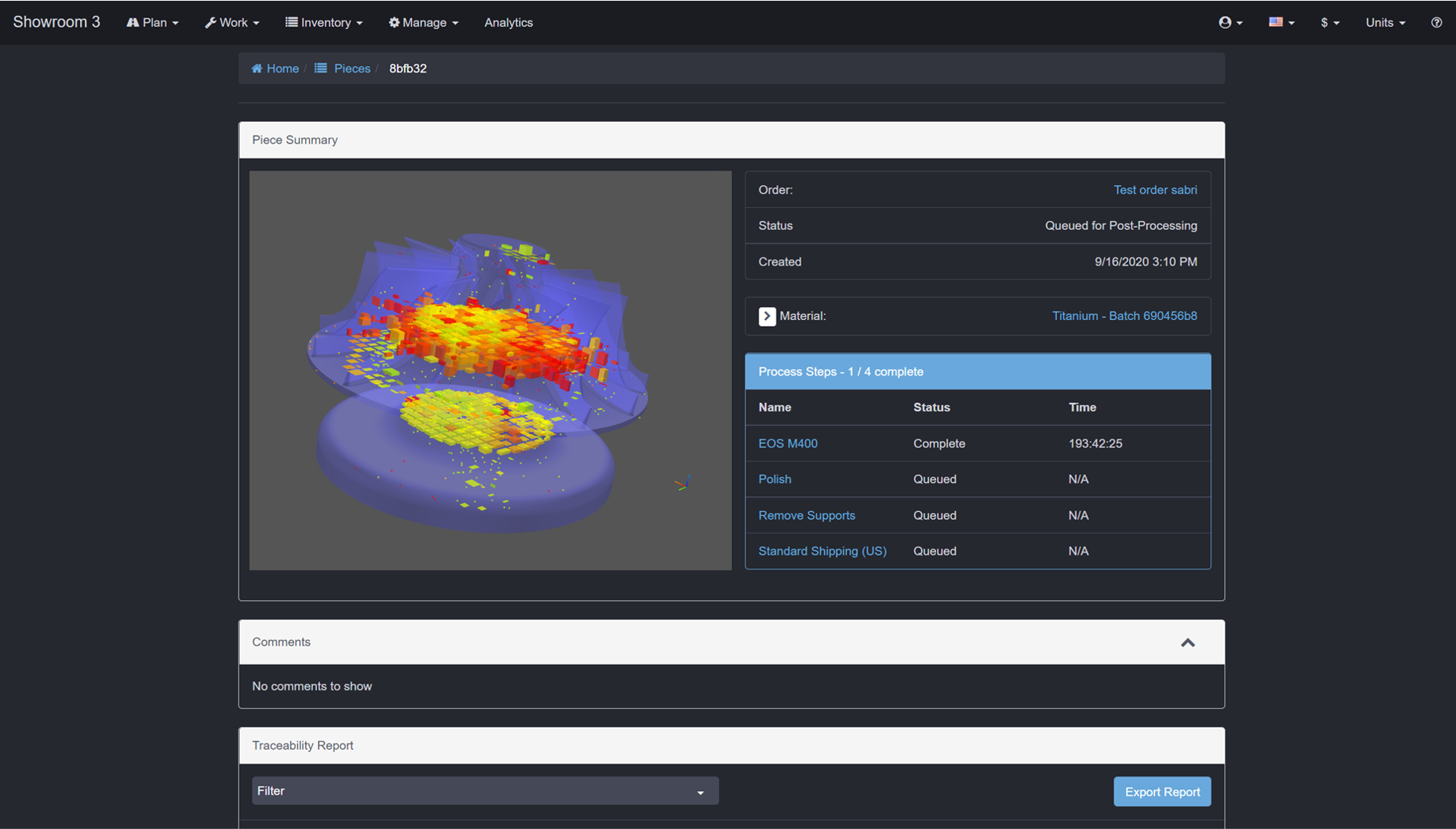

nebumind’s digital twin visualizations bring together sensor data and machine parameters with original part geometry in order to form a complete visual representation of production data that can then be analyzed for product quality and machine process stability.

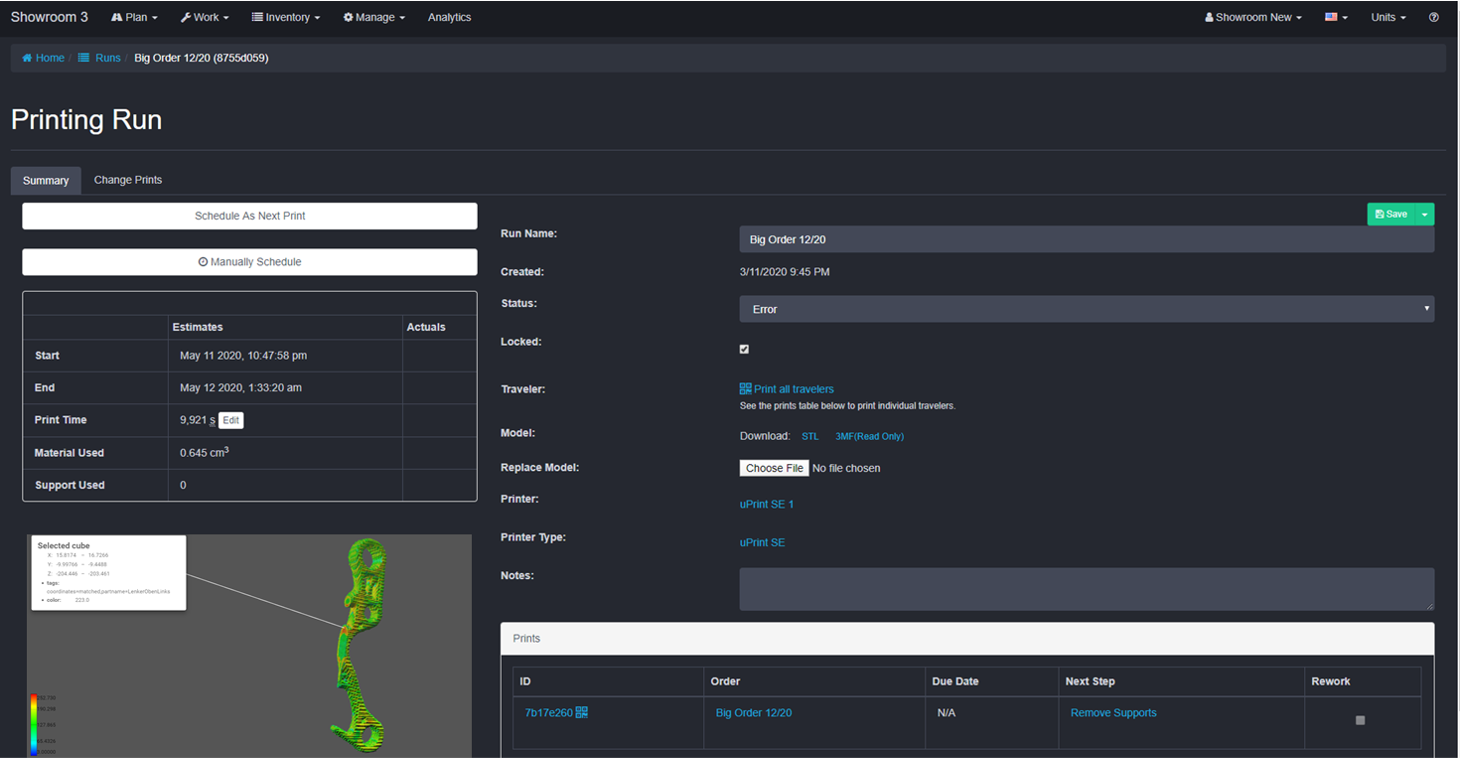

Through the partnership, this tool is being integrated into Authentise’s AMES workflow management system to allow users to more easily and quickly address deviations or problems during the printing process, while also providing end-to-end traceability for parts. AMES is an additive workflow management engine that collects data from 3D printers to smoothly generate order status updates, automated actions, and system optimization reports.

Incorporating nebumind’s digital twin with AMES could reportedly help customers identify if a part needs to be reworked up to 10 times faster, and achieve a 90 percent reduction in rejected parts.

“Manufacturers in general are playing catch up when it comes to digitization and these benefits make their adoption of the digital thread more likely, and the tools more powerful thanks to a more dynamic market,” added Albert.

Improving accessibility of AM digital threads

Today, the companies announced they have received funding from the EU via Digifed, the value of which is undisclosed, to further their partnership and continue their efforts to make digital threads more accessible to additive manufacturing users.

Operating within the framework of the Smart Anything Everywhere Initiative, DigiFed seeks to boost the adoption of advanced digital technologies by EU SMEs with a focus on non-digital businesses.

“We’re delighted to have been selected for this highly competitive program by the European Union,” said Andre Wegner, CEO of Authentise. “It not only speaks to the power of nebumind’s digital twin visualization solution but also validates the Authentise approach. Unlike many larger companies, we explicitly don’t want to build or own everything ourselves. We’d rather partner.”

According to Wegner, partnering with companies such as nebumind to improve workflow management and part data within the 3D printing sector, frees the company up to solve other challenges in the industry.

“It also makes sense for customers because they save time from no longer having to interact with multiple software solutions and are guaranteed cutting edge solutions by specialization and constant innovation,” he added. “We’re delighted that the EU has recognized this and is supporting this integration.”

Just last month, Authentise announce another partnership with the Manufacturing Intelligence division of Hexagon AB, a Sweden-based global technology company, to develop an end-to-end software offering designed to make 3D printing more predictable, repeatable, and traceable.

The companies intend to accelerate the industrialization of 3D printing through their partnership by digitizing each step of the workflow, from part design through to production and quality assurance.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an alert in the Authentise web app. Image via Authentise.