August 2016 was a good month for 3D printed medical applications. There was a trend for bespoke prosthetics, both in businesses and at home and, taking note of the spread of the Zika virus across most of North and South America, a student developed a 3D printed kit to detect such diseases and stop them from spreading further.

3DPI also got an exclusive glimpse at advanced additive manufacturing research at DARPA in an interview with their project director Mick Maher.

9-Year-Old 3D Printing Enthusiast Prints Prosthetic Hand for Teacher

Calramon Mabalot from California is, according to his official Twitter profile, ‘unofficially the youngest person in the world to build a 3D printer’. He did so in 2015 at the age of 8, and since then he and his brother have become 3D printing service providers through 3D Hubs under the name Brother Robot.

In August 2016, 3DPI reported how the brother and father team worked together to make a prosthetic arm for a high-school teacher they had met learning CAD modeling in a local library. He did so through the use of 3D scanning, Colorfabb filament, strings and a little trial and error, as documented in a series of videos on Twitter he says ‘We’re gonna have to re-print the pinky!’.

For the rest of 2016, Calramon and Calexis have been catching up with professionals at industry fairs, such as RoboUniverse, and is hardly ever out of South California’s MatterHackers store. Brother Robot also won the first Frontier Tech Young Entrepreneurs award this year at the Inside 3D Printing Conference & Expo in San Diego.

On the topic of prosthetics, (which I believe we’re going to see even more of in 2017), 3DPI also caught up with Sophie de Oliveira Barata on her Phantom Limb Project creating alternative prosthetics.

Student uses 3D printing to prevent spread of Malaria, Zika, and infectious disease

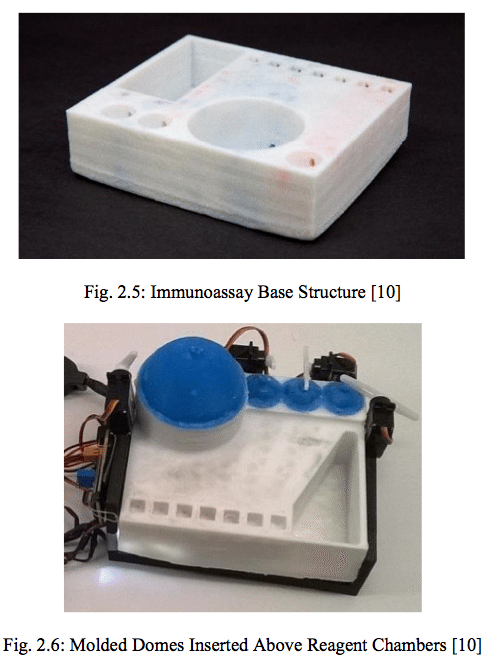

With diseases like Zika and Malaria flying as fast as mosquitoes’ wings can carry them, detection is key to nipping the illness in the bud. At the University of California Irvine (UCI), researchers are trying to create a simple solution to the problem of providing test-kits to those without immediate access to healthcare.

Through the use of additive manufacturing, Chris Lin and his UCI associates propose a cost-effective and timely method for making a disease-detecting kit.

DARPA’s advanced 3D printing research, interview with Mick Maher

At the beginning of August 2016, 3DPI editor-in-chief Michael Petch spoke to DARPA’s Mick Maher of advanced manufacturing. In the interview, Maher sheds light on the ‘3 strands’ of DARPA’s additive manufacturing methods, in particular the development of the Rapid Low Cost Additive Manufacturing (RLCAM) and Titanium Fabrication (tiFAB) efforts.

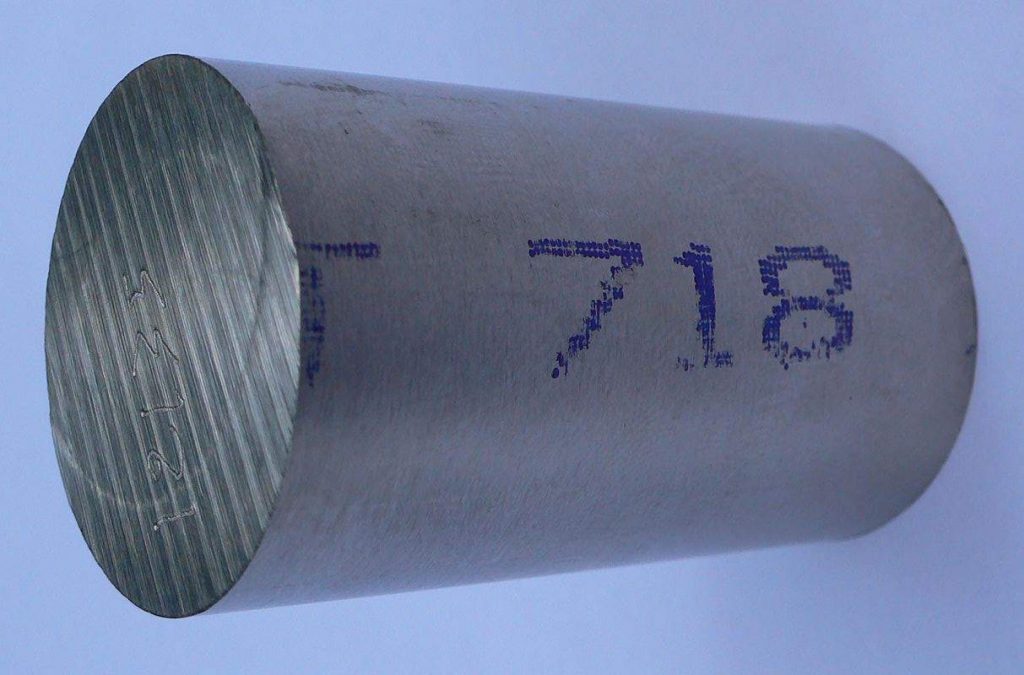

Unsurprisingly, the materials being used in both initiatives have become something of a hot-topic, particularly within the aerospace industry and with NASA. In RLCAM DARPA are looking into the AM possibilities of Inconel 718 – the ‘superalloy’ that performs as well in high temperatures as it does far below zero. And in tiFAB, the Agency are using Electron Beam Additive Manufacturing (EBAM) with wire based ‘filaments’ of various strains of Titanium.

If you’d like to read more about DARPA’s projects you can revisit the full interview here.

Is there something we missed from August 2016? If so, you can let us know via email here, or you can nominate your favorite 3D printing developments for our first ever 3D Printing Industry Awards 2017 here.

Featured image shows Calramon Mabalot and the teacher he helped with a 3D printed prosthetic hand. Photo via Calramon Mabalot on Twitter