Rapid identification of infectious disease outbreaks can be vital in limiting damage and coordinating an appropriate response. While modern drugs can combat many of these diseases, in developing countries the lack of ready access to lab equipment can delay diagnosis. 3D printing is playing a role in changing this situation.

Chris Lim, University of California Irvine (UCI) student and his thesis “Fabrication of Elastomer Microfluidic Devices using Additive Manufacturing Methods” are part of the solution.

Under the supervision of UCI Professor Marc Madou, Associate Professor Regina Ragan and Dr. Lawrence Kulinsky, Lim has examined two common 3D printing techniques as methods to fabricate microfluidic devices. His work builds on that of UCI PhD student Maria Bauer and looks at reducing the cost of sophisticated technology necessary to correctly identify diseases such as malaria.

Gold medal for microfluidics

While Olympic competition takes a break until September, 3D printing is contending with a different kind of event. In terms of interdisciplinary knowledge additive manufacturing is a strong contender for the decathlon medal. However, Microfluidics presents a justified challenge given the physics, engineering, nano, bio and chemistry knowledge demonstrated by its practitioners.

But what happens when you combine the two? Is it Michael Phelps meets Usain Bolt or Ryan Lochte meets an excessive amount of Caipirinhas?

Microfluidics involves the manipulation of liquids through mechanical means or via passive control, such as the capillary action first observed by Leonardo da Vinci. MIT physics professor and Fab Lab pioneer, Neil Gershenfeld has proposed a “bubble-logic” microfluidic system to supplant the flawed state of modern computing.

Researchers have combined microfluidics with landscape ecology to understand evolutionary biology and to develop non-conventional fuel cells. For now, Lim is content to deploy microfluidics in the study of disease.

3D printing a disease detection platform

Lim explains that elastomers offer an appealing prospect for investigation,

“An octopus is able to deform itself and squeeze through a hole a tenth of its own cross sectional area, all while maintaining its ability to move rapidly in water.”

Mimicking nature and using elastomers could enable a drug delivery capsule that, “can precisely deliver a drug through selective opening and closing of a valve controlled by a dielectric actuator.”

With this in mind, Lim used thermoplastic polyurethane (TPU) to build “flexible microfluidic structures.” The author worked with the Airwolf 3D and Flashforge Creator 3D printers to research the FDM aspect of his thesis and used the Formlab’s Form 1+ for the SLA component of his thesis.

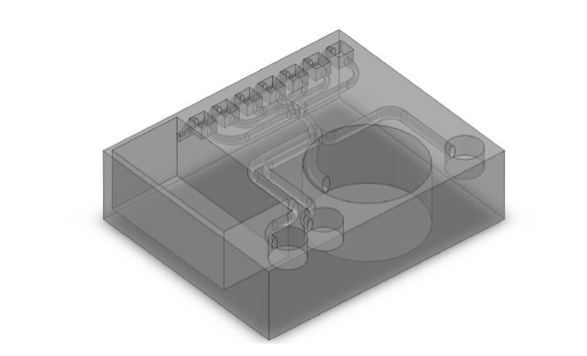

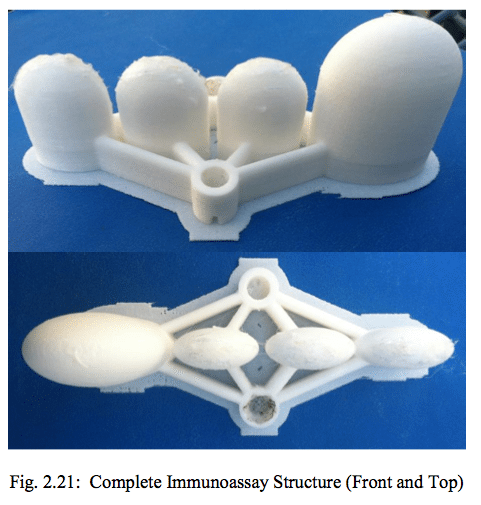

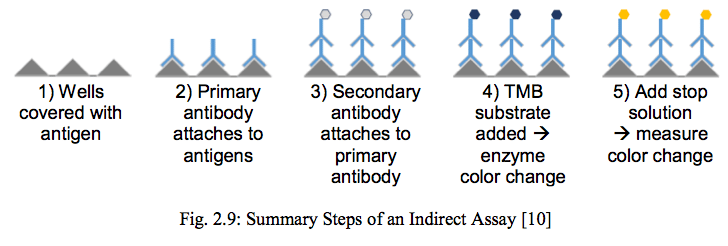

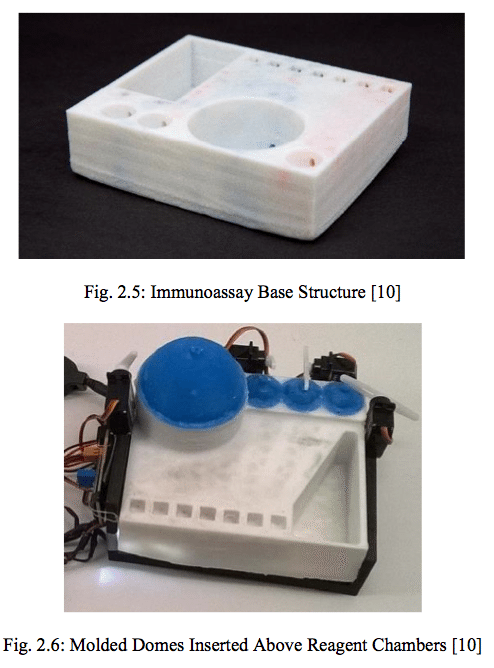

A particular interest was the fabrication of a, “disease-detecting immunoassay platform.” This is a device that can be used to detect the presence of diseases such as malaria in a sample. UCI PhD student Maria Bauer had created such a tool using the enzyme-linked immunosorbent assay (ELISA) approach.

“ELISA detects the presence of a specific antigen in a sample and is one of the most widely used assay techniques today,” writes Lim. This process binds antibodies and proteins together and immobilizes the molecule of interest to the analyst.

Lim’s method creates, “a stand-alone platform that is intended to be used in developing countries without access to expensive automated workstations.”

3D printing enabled Lim to perform a number of iterations of the device. During the work Lim found, “circular structures were generally much more stable than non-circular ones.” Control of the print speed was an important variable and necessary to monitor to avoid stretching and its consequences.

“A consequence of filament stretching is porosity. Compare the stacking of non-uniform diameter filaments to the stacking of wooden logs. A series of logs with uniform diameter would fit easily together without much internal stress. However, if the diameters were all decreased at the center and increased at the sides, the stack of logs would eventually collapse due to an uneven distribution of weight.”

A “living hinge”

Decreasing the size of devices presents a number of advantages, including, lower material costs, reduced consumption of reagent’s and sample material, increased sensitivity and also superior portability. 3D printing has demonstrated application in several of these areas previously.

In addition to reducing the amount of material consumption, Lim also looked at how to save another important resource, time. Performing an assay requires the technician to introduce samples and testing chemicals at specific intervals. This allows reactions to take place as the sample material as time to incubate and proliferate. In the case of the malaria test this time,

“totals to almost two hours of incubation, and does not include the time required to pipette the samples and reagents into the wells between each incubation step.”

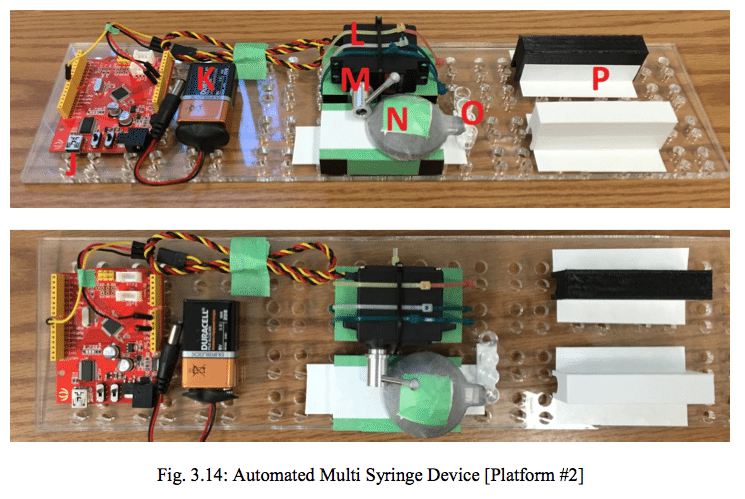

Lim researched ways to automate this process, “through a series of servomotor-controlled syringes to dispense the appropriate reagents after each incubation period without any human interaction.” His work was successful in creating a proof of concept device using components fabricated on both FDM and SLA 3D printers and an Arduino board to control the servomotors.

Lim says that future work might include fabrication of a living hinge for drug delivery applications. This could involve a reagent, “stored within a chamber and dispensed with the opening or dissolving of a flap of flexible resin.”

Lim concludes that, “the ELISA assay that was fabricated using both FDM and SLA techniques was far superior in retaining fluids within enclosed chambers.” However, this is not the most optimal solution as it requires an amount of post-printing assembly. Further research may involve simplification of the design to ensure parts can be joined together with minimal effort.

Rapid research with 3D printing

Assaying, or testing, is a bane of many under and post-graduate’s lives. The provision of a method to accelerate and automate this removes a key constraint on the process of discovery, a researchers time. Increasing throughput can free up this valuable resource for more critical work.

Our understanding of disease and human biology was held back by a recalcitrance to embrace a new method of cell culture. When Mina Bissell presented her model for creating three-dimensional in vitro environments in the 1980s she was met with resistance. Now, this is the standard methodology.

Furthermore, the miniaturization of devices and concepts such as the lab-on-a- chip serve to improve health on a global basis. Expensive diagnostic tools are frequently beyond the means of many clinics in the developing world. Devices such as this reduce the need to depend on referral to a laboratory and may assist in the early identification and treatment of infectious diseases.

Having completed his thesis, Lim is now looking for the next opportunity to work with additive manufacturing.