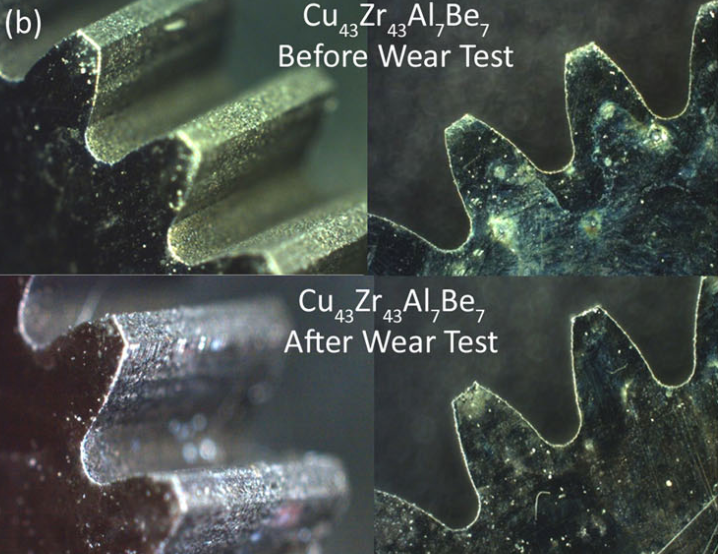

A team led by technologist Douglas Hofmann at NASA’s Jet Propulsion Laboratory (JPL) in Pasadena, California, is reinventing the gear – using an advanced amorphous metal that works well in the -328 degrees Fahrenheit (-200°C) temperatures of space. The gear fabrication by Hofmann’s team. is an experiment in the casting of bulk metallic glasses (BMGs) a metal alloy that has a molecular structure like glass, and can be found in the journal of Advanced Materials Engineering here.

The amorphous structure of BMG means that it can be easily manipulated/blown whilst retaining metallic strength and conductive properties. It is also highly scratch-resistant and works well without the use of a lubricant.

The mystery of amorphous metals and how they may help find life near Jupiter

BMG’s are used by some manufacturers but Hoffman explains that ‘understanding how to design and implement them into structural hardware has proven elusive’. He went on to add that,

In collaboration with groups at Caltech and UC San Diego, [JPL] have finally put BMGs through the necessary testing to demonstrate their potential benefits for NASA spacecraft. These materials may be able to offer us solutions for mobility in harsh environments, like on Jupiter’s moon Europa.

JPL are developing a mission Europa because NASA believe it may be our best option for finding life on a planet other than our own. Results from previous fly-bys of Jupiter’s smallest moon suggest that there may be an ocean hidden under Europa’s crust, and that it sends plumes of water out into the atmosphere. With a date set for the early 2020’s, applying BGMs to the manufacturing of a Europa rover could be crucial to the project’s acceleration.

The trinity of additive manufacturing

Casting BMG to make gears is cheaper than the common way of tooling the parts. Another method of potentially lowering the production cost is of course through additive manufacturing, and a collaboration earlier this year managed to do just that.

Swedish startup Exmet materials technology partnered with the German Heraeus Metal Processing Group in the successful launch of additive manufacturing BMGs – a process achieved by using specially developed metal powders.

The apparent low-cost potential is an attractive prospect considering the continual cuts being made to the US government’s budget for NASA. Not only that, but cheaper materials can take the strain off other industries feeling budget pinches.

It’s all part of the trinity: Materials, hardware, software – As one develops the others must too. This means as we look to new frontiers in space exploration, we simultaneously hold materials and methods that can be applied to other areas of manufacturing and technological developments, which both ultimately trickle down into the way people live.

If you liked this story on the possibilities of additive manufacturing in space, you can sign-up to our newsletter here for more upcoming space stories.

Featured image shows a real color photo of Jupiter, taken by the Cassini Orbiter. Via: NASA/JPL