Following news of a recent $5.2 million Series A funding round, UK-based post-processing specialist Additive Manufacturing Technologies (AMT) has announced plans to utilize the investment to fund its global expansion activities.

Comprising efforts in key global regions such as the Asia Pacific (APAC) region, as well as North America, these activities include new key appointments and the opening of a new headquarters in Texas. Joseph Crabtree, CEO of AMT, commenting on the company’s increased global presence, stated, “This is a really exciting time for the growing AMT team. We have secured the investment and key partnerships to take the company to the next level and it is gratifying to witness this becoming a reality across the world.”

“The global reach of AMT is not just about the company, it is about creating real opportunities for manufacturing companies across the world to leverage the real benefits of additive manufacturing and 3D printing in a cost-effective and sustainable way through automated post-processing.”

Expanding post-processing into the Asia Pacific market

To support its expansion into the Asia Pacific region, AMT has appointed Damson Lai as APAC Market Director, alongside creating a dedicated business development and sales strategy. Lai is based in Taipei, Taiwan, and joins AMT from Teco Image Systems (TIS), a global provider of OEM and ODM services in the imaging and communication products industries.

Working for TIS, Lai was responsible for establishing 3D printing strategies for major OEMs of traditional consumer and business printing equipment, where he has gained experience in identifying critical applications for the technology.

AMT plans to utilize Lai’s expertise and understanding of the entire process chain to help develop relationships across the APAC region. “AMT is at the cutting-edge of automated post-processing technology, which is exactly what the industry requires,” Lai commented. “The costs and labor involved [in post-processing] can make [3D printing] unviable. AMT’s post-processing solutions change that dramatically and can really bring AM to the next level for a whole range of customers with an attractive business model.”

AMT is also continuing to expand its presence in the US with the construction of the company’s new US HQ in Austin, Texas. The facility is planned for opening by the end of 2019.

Boundary layer automated smoothing technology

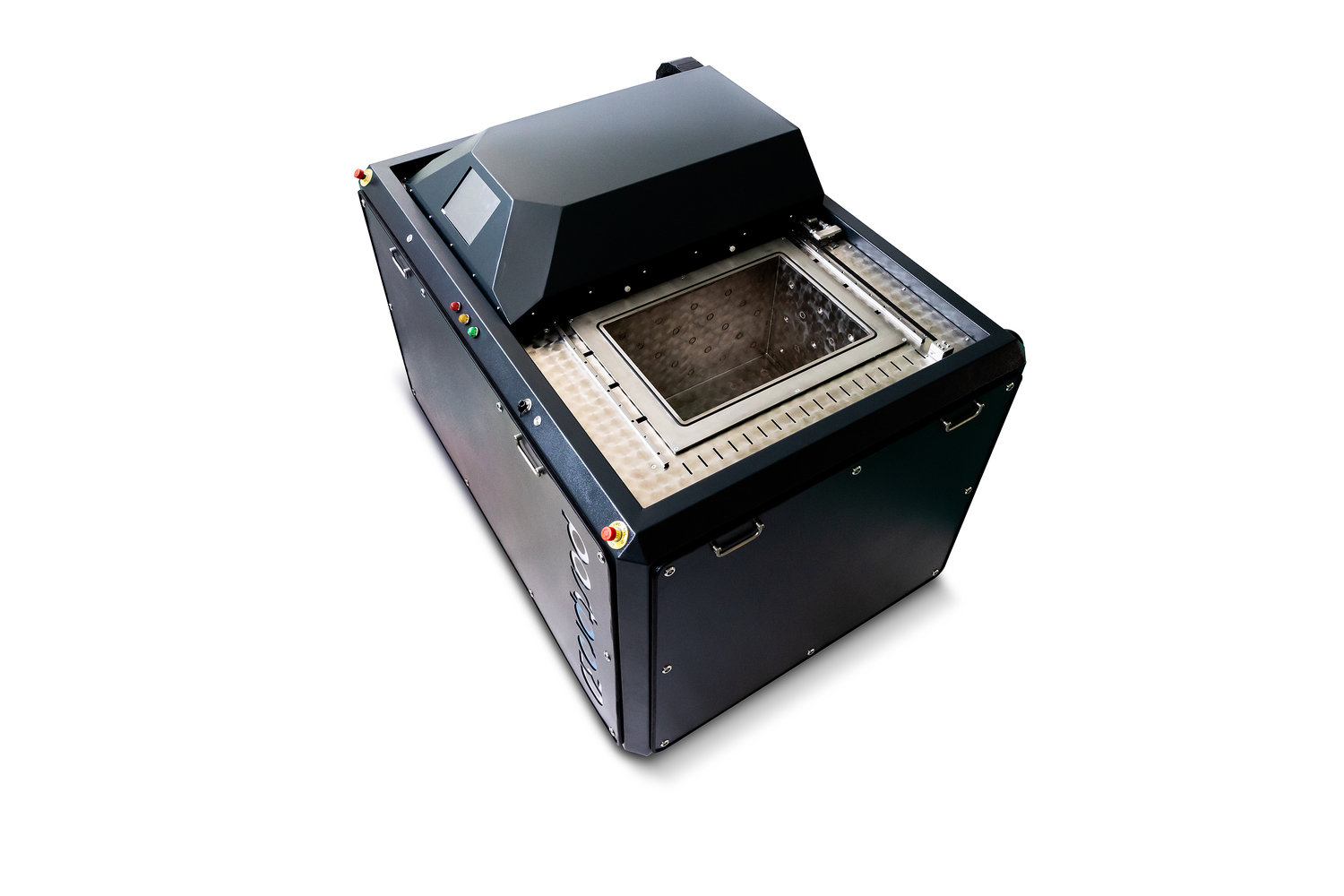

AMT’s post-processing solutions consist of the PostPro3D system, launched in September 2018. It is designed to smooth and seal 3D printed parts to make them suitable for end-use applications, equipped with a process chamber of 600 x 400 x 400 mm. The company also unveiled two new automated post-processing systems, the PostPro3DColor and PostPro3DMini, at RAPID + TCT 2019. The PostPro3DColor system is capable of 3D printed parts in a single step. PostPro3DMini is a smaller version of the original PostPro3D with a process chamber of 300 x 350 x 300 mm.

Each of the company’s post-processing machines is based on its Boundary Layer Automated Smoothing Technology (BLAST), which was developed at the University of Sheffield‘s Advanced Additive Manufacturing (AdAM) Centre. The BLAST process supports various 3D printing technology such as powder bed fusion, HP Multi Jet Fusion, High-Speed Sintering, and FDM/FFF.

AMT will be attending this year’s Formnext show, at Hall 12.1, E61, where attendees can have a look at the company’s automated post-processing solutions. AMT also plans to introduce the commercial version of its Digital Manufacturing System at the event, which is intended to be a fully integrated post-processing solution. The Digital Manufacturing System uses de-powdering, surface modification, and coloring to automate each of the manual post-processing steps. Furthermore, AMT will be exhibiting at Formnext from a unique, modular stand created using over 6000 3D printed, post-processed parts.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows from left: Joseph Crabtree, CEO and Luis Folgar, EVP Americas in the new AMT facility in Austin, Texas. Photo via Additive Manufacturing Technologies.