UK-based post-processing specialist Additive Manufacturing Technologies (AMT) has announced the completion of a $5.2 million Series A funding round. The round was led by DSM Venturing, the venture capital arm of global material producer Royal DSM, Foresight Williams Technology EIS Fund, an enterprise investment scheme formed by private equity firm Foresight Group LLP (Foresight), and the venture arm of Williams Advanced Engineering.

AMT will use the newly raised $5.2 million funding to commercialize its post-processing technology.

“We are delighted to announce our Series A funding round,” stated Joseph Crabtree, AMT’s CEO. “This investment is another important step in accelerating AMT’s vision of an integrated digital manufacturing system that will deliver end-to-end solutions from material selection to part finishing for any industrial end user manufacturing process.”

“We look forward to making AMT the world leader in automated post-processing technology.”

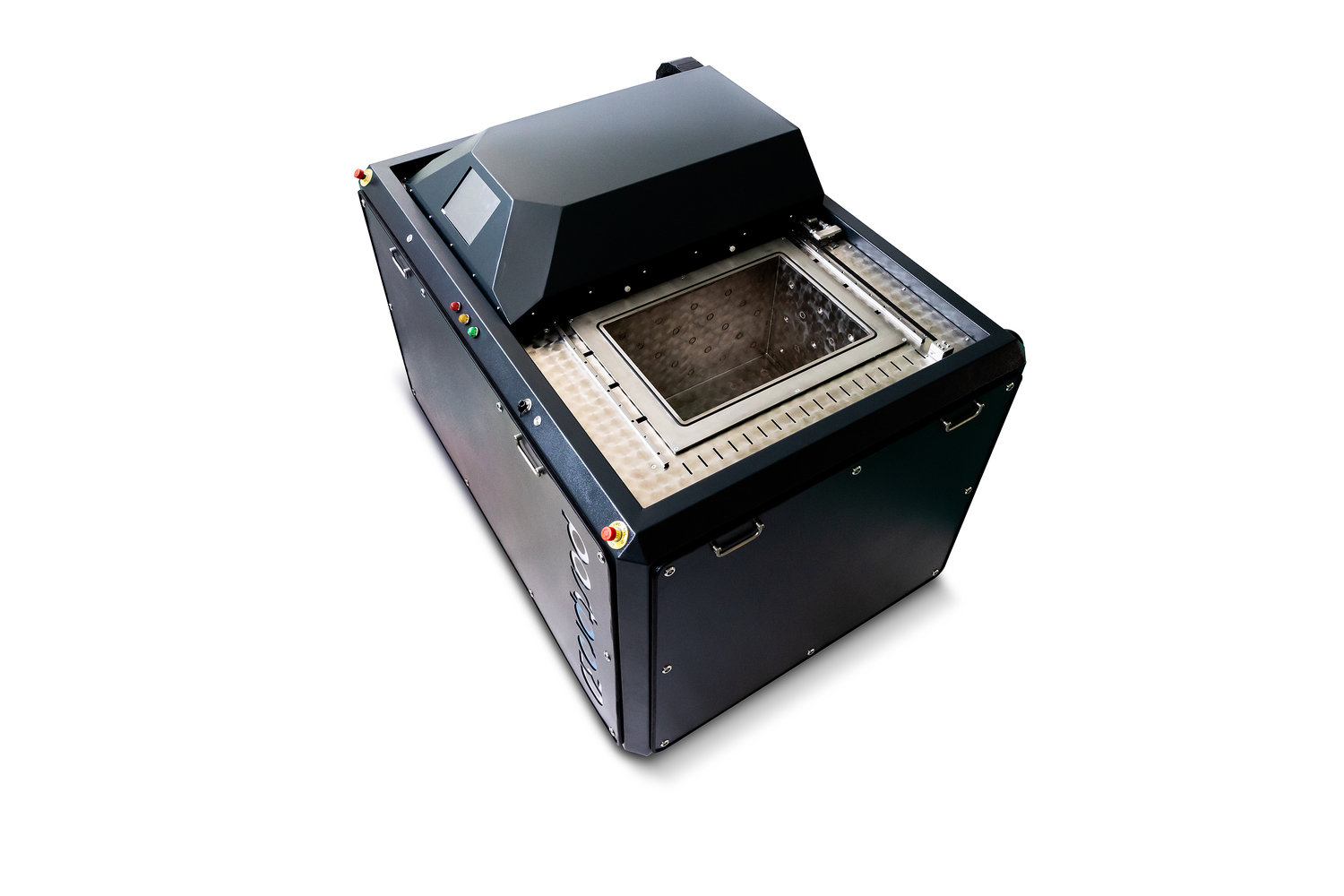

AMT’s PostPro3D technology

Founded in 2017, AMT manufactures automated post-processing systems for 3D printed parts. It is headquartered in Sheffield, with a manufacturing facility in Hungary, and a North American HQ in Austin, Texas planned for opening in Q4 2019. The company claims that a significant amount of manufacturing costs in 3D printing can be attributed to the highly manual steps of post-processing. This involves the laborious process of cleaning and polishing a part after it has been 3D printed.

Aiming to “unlock the use of 3D printing for high volume production,” AMT’s post-processing systems are intended to help customers automate their manufacturing workflow. Its technology centers on a proprietary method called Boundary Layer Automated Smoothing Technology (BLAST), which was developed at the University of Sheffield‘s Advanced Additive Manufacturing (AdAM) Centre.

The company’s first commercial system, the PostPro3D, was launched in September 2018. Certified by third party regulatory bodies, the PostPro3D is able to finish 3D printed components into a sealed and smoothed part suitable for end use applications using BLAST technology. AMT claims the quality of the parts matches those produced using injection molding. The PostPro3D is compatible with various polymer 3D printing technologies such as powder bed fusion, HP Multi Jet Fusion, High Speed Sintering, and FDM/FFF.

At RAPID + TCT 2019 in May, AMT also unveiled two new automated post-processing systems, the PostPro3DColor and PostPro3DMini. The PostPro3DColor system, along with smoothing 3D printed parts, is also capable of coloring them in a single step. PostPro3DMini, on the other hand, is a smaller version of the original PostPro3D with a process chamber of 300 x 350 x 300 mm.

Commercializing post-processing technology

AMT’s Series A round follows a £624,000 ($782,000) grant from the UK government’s Technology Strategy Board Innovate UK in 2017. Furthermore, the company has previously received seed investment by Midwest Additive Ventures and NPIF-Mercia Equity Finance through Mercia Asset Management PLC.

Using the new funding, AMT plans to accelerate the sales of its post-processing systems. It also aims to deliver a commercial version of its Digital Manufacturing System, which is intended to be a fully integrated post-processing solution. The Digital Manufacturing System uses de-powdering, surface modification, and coloring to automate each of the manual post processing steps.

Commenting on the investment, Pieter Wolters, Managing Director of DSM Venturing, stated: “AMT is revolutionizing the world of post processing of 3D printed parts, thus enabling additive manufacturing to become a competitive alternative for industrial scale production. We are excited about including AMT in our additive manufacturing investment portfolio and supporting the company in accelerating its growth.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows parts 3D printed with EOS PA2200, post processed on the PostPro3D. Photo via Additive Manufacturing Technologies.