In this latest edition of the 3D Printing Industry news digest Sliced, 3D printing sets a new Guinness World Record; we get a preview of the show floor at Formnext; NASA invests its future in 3D printing; and various distribution deals are made across the industry.

Read on for updates from the likes of BCN3D Technologies, Prusa Research, Copper 3D, BeamIT, ParaMatters and more.

The Mud Frontiers

RAEL SAN FRATELLO, an Architectural design studio in Oakland, California, is exploring sustainable and ecological construction through the creation of four 3D printed mud structures. Through its 3D printing “MAKE-tank” Emerging Objects, these structures are a result of the Mud Frontiers project, which mimic indigenous coil-and-scrape pottery.

Innovative 3D printed structures will also be present at Formnext this year. As well announcing its exit from stealth mode over the last 12 months, UK-based post-processing systems manufacturer on Additive Manufacturing Technologies (AMT) will be present at the Formnext show floor with a unique stand. The company will be presenting and exhibiting from a modular, fully customizable and reusable 84 metre square stand construction, created using over 6000 3D printed parts in collaboration with Steel Roots Design. Each of the components have also been post-processed, and they connect 1100 metres of lightweight aluminium tubing to create the 4m high booth.

Other 3D printing events happening soon includes the Aerospace Additive Manufacturing Summit (AAMS), taking place from 3 to 4 December 2019 at the Diagora-Labège congress centre in Toulouse, France. This international business convention, dedicated to additive manufacturing in the aerospace industry, is returning for its second show, with the first edition having taken place in 2017. The first AAMS saw 200 companies representing 15 different countries in attendance.

The most 3D printers operating simultaneously

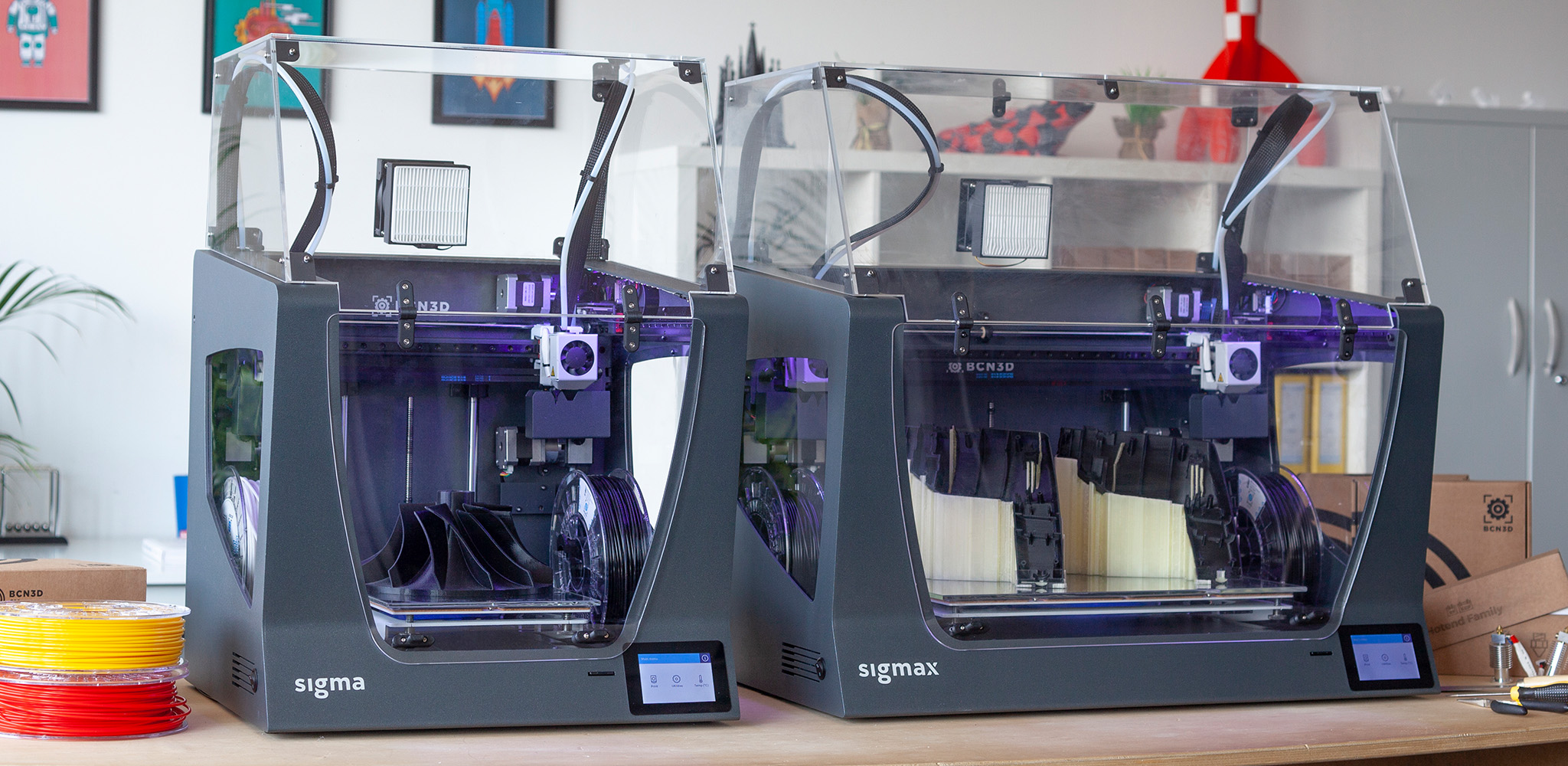

BCN3D Technologies, the Barcelona-based open-source 3D printer manufacturer, and Global 3D, a Polish 3D printer reseller, have announced a new partnership, with the signing of a distribution agreement. Global 3D will now sell BCN3D’s Sigma and Sigmax 3D printers across the Polish market, as well as the company’s full range of filaments, accessories and spare parts. “We are pleased to cooperate with Global 3D, which will support us to increase the sales in a polish market that has high potential for the IDEX system and the distinctive duplication, mirror and multimaterial printing mode. The considerable experience in additive manufacturing combined with a top-quality technical know-how makes Global 3D the right fit to help us to grow and serve polish customers in an excellent way,” states Xavi Martínez Faneca, CEO of BCN3D Technologies.

Another distribution deal this week come from Copper 3D, a US-based Chilean 3D printing materials company, which has announced a new African distribution and agreement with Kuunda3D, a 3D printing reseller based in Kenya. Copper 3D is known for developing 3D printing materials which have antibacterial properties, for which it has received funding from the likes of NASA. The company recently announced the appointment of 3D Universe as its North American reseller as well.

Award winning open source 3D printer manufacturer Prusa Research has also set a new world record for the “Most 3D printers operating simultaneously.” The company collected all the 3D printers located within its headquarters in Czech Republic, totalling to 1096 3D printers, and set them running concurrently in the facility’s basement. The record was officially confirmed by a representative of Guinness World Records. The previous record was set in 2014 by California-based Airwolf3D with 159 machines running simultaneously.

BeamIT, an Italian additive manufacturing service bureau, has installed its fourth M 400-4 3D printer from leading 3D printer manufacturer and service provider EOS. The system, a quad-laser metal 3D printer, will be used by BeamIT to manufacture components for the oil and gas industry. BeamIT recently expanded its additive manufacturing portfolio with the addition of two 3D printers from SLM Solutions as well. Mauro Antolotti, Chairman of BEAMIT, commented, “Industrial 3D printing has proven to be a real revolution for countless industrial sectors and we see even more viable potential.”

“So we are delighted to scale our 3D printing production capabilities by strengthening our collaboration with EOS.”

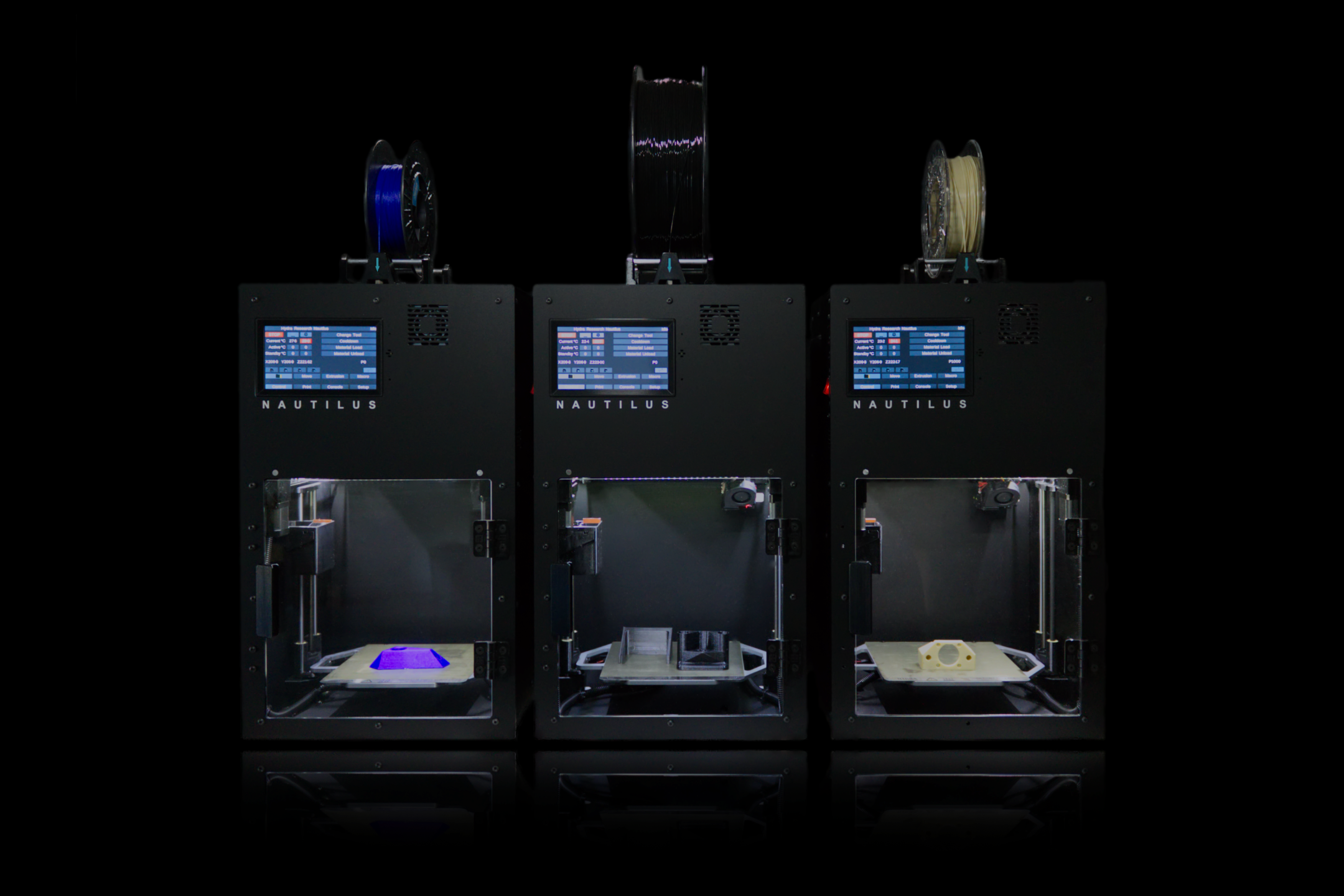

Hydra Research, a 3D printer manufacturer based in Portland, Oregon, has announced the release of Nautilus, its new flagship desktop 3D printer. An open source, community-led 3D printer, the Nautilus features components from the likes of Duet3D and E3D. For example the 3D printer’s “Tool Cartridge” system feature an E3D V6 HotEnd. It supports a wide range of materials, including ABS, Flexible, Nylon, and fiber composites, and comes packed with integrated software. “As a company, our primary goal is producing world-class hardware on an open source platform. Manufacturers like E3D, Duet3D, and Fillamentum combine these values perfectly,” commented John Kray, Founder and CEO of Hydra Research.

Training space engineers of the future using 3D printing

NASA has awarded a $420,000 grant to Delgado Community College to in an effort to train potential employees. The grant will help place minority students on a STEM career path, with an emphasis on advanced manufacturing in space applications. As well as receiving up to $5,000 in scholarships, students will also be able to complete a week-long field trip to the University of Louisiana at Lafayette. There they will get to participate in the Additive Manufacturing Project for the In-Space Manufacturing of Lightweight Metal Alloys. “This funding will enable Delgado to meet the needs of this industry by providing students with relevant training to prepare them for careers in space advanced manufacturing,” stated the Delgado chancellor Larissa Littleton-Steib.

As part of an educational cybersecurity challenge, a student at the U.S. Naval Academy has discovered a new vulnerability in a 3D printer. The cyber challenge, HACKtheMACHINE, was held aboard New Lab at the Brooklyn Navy Yard. 19 year old Kade Heckel made the discovery, who is part of the U.S. Naval Academy Midshipman 3rd Class. The exposure of the vulnerability is expected to have a real-world impact on the fleet and inform the decisions made onboard ships.

High performance mountain cycling enabled by 3D printing

Foundry Research Institute (FRI), a research facility based in Poland, has partnered with Californian software company ParaMatters in order to develop a lightweight automotive suspension upright. The component was processed through ParaMatter’s CogniCAD generative design and topology optimization software, and then investment casted using a Voxeljet 3D printed mold. Six designs were imported into CogniCAD, with defined parameters to minimize the mass under strength constraints. The capabilities of ParaMatters generative design software enabled the creation of a lightweight suspension upright, said to be 45% lighter than the original component.

“CogniCAD provided a huge range of options and a high degree of flexibility to create a lightweighted design for a challenging application,” commented Michael Bogomolny, PhD, co-founder and CTO at ParaMatters.

“By combining automatically AI-generated design to 3D printing and investment casting, we were able to create a suspension upright that was almost half the weight of the original part and could be mass manufactured at low cost.”

Radic Performance, a mountain bike component manufacturer, has launched a new Kickstarter campaign for its 3D printed Radic GAMMA mountain bike brakes. Available for $312 NZD ($197 USD), the 3D printed brakes are designed to offer high performance when cycling. They are manufactured using AlSi10Mg Aluminum Alloy and weigh less than 60 grams. Furthermore, the Radic GAMMA brakes feature an open design, for allowing increased airflow, which helps to keep the brake temperatures low.

REGEMAT bioprinting

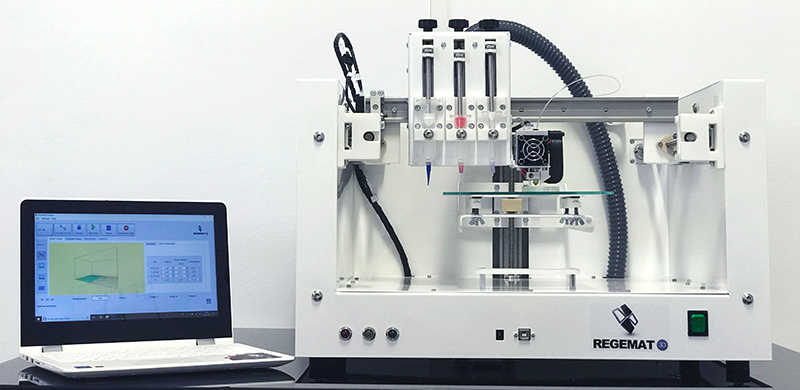

REGEMAT 3D, a Spanish biotech startup, has seen its technology used by a number of researchers for a variety of medical purposes. Vicente Linares, a research collaborator and doctoral candidate of the Faculty of Pharmacy at the University of Seville, was able to manufacture pharmaceutical dosage forms using REGEMAT 3D’s V1 bioprinter.

Francisco Jose Calero Castro, a specialist in biomedical investigation also based in Seville, used REGEMAT 3D biotechnology to test the fabrication of a 3D mesh to simulate prostheses for the treatment of hernia.

Finally over in Norway, a biocomposite scientist at the RISE PFI AS research institute by the name of Garry Chinga Carrasco used the V1 to produce dressings for skin abrasions and similar applications, like the printing of tissue models.

Arkema increases global capacity by over 50 percent

Smith Bits, a drill bit manufacturing subsidiary of global oilfield services company Schlumberger, has introduced a new line of additive manufactured armor cladding, titled Aegis, designed to improve the performance of bits. Drill bits are the cutting tools used on drills to remove material and create holes. The new Aegis armor cladding is intended to improve bit body design flexibility, while improving its erosion resistance, rate of penetration and durability for longer runs. It is manufactured using an electron-beam additive manufacturing (EBAM) process. “Our new armor cladding technology combines innovative materials science with an electron-beam additive manufacturing process,” said Kristi Vilay, president, Bits & Drilling Tools, Schlumberger. “This new manufacturing approach allows us to integrate a new proprietary material into our customized, fit-for-basin bits, providing a differentiated technology to improve our customers’ overall drilling performance.”

Arkema, a French advanced materials company, has expanded the production capacity of its Orgasol specialty polyamide 12 powder at the Mont plant in France, with an investment of €20 million ($21.9 million). Orgasol is made through a unique patented polymerization process which creates its small and complex controlled particle size distribution. Due to its notable strength, viscosity, stability, and contour resolution, Orgasol has been used for a range of industrial applications in 3D printing. “The Mont site has a long, proven legacy in the production of specialty powders,” commented Erwoan Pezron, Global President of Arkema’s Technical Polymers Business Line. “With this new production capacity, we continue to actively support our customers’ continued growth in cutting edge applications, notably in high performance coatings, composites and 3D printing.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows featured image shows Sliced Logo on image of 3D printed Mud Frontier structure designed by RAEL SAN FRATELLO. Original photo via RAEL SAN FRATELLO.