Airbus Helicopters, the helicopter manufacturing division of Airbus, has announced the commencement of large-scale production of 3D printed latch shafts for its A350 aircraft in its Donauwörth, Germany facility.

The latch shafts, which are used for the doors of the helicopter, are redesigned with lightweight properties and are manufactured using an EOS M 400-4 printer. Luis Martin Diaz, Head of Industrial Service Centers, Airbus Helicopters Donauwörth stated:

“Weight savings are especially important when it comes to helicopters. 3D printing should be taken into consideration right from the initial planning stages for new components, which may be able to be manufactured particularly easily and cost-effectively using this method.”

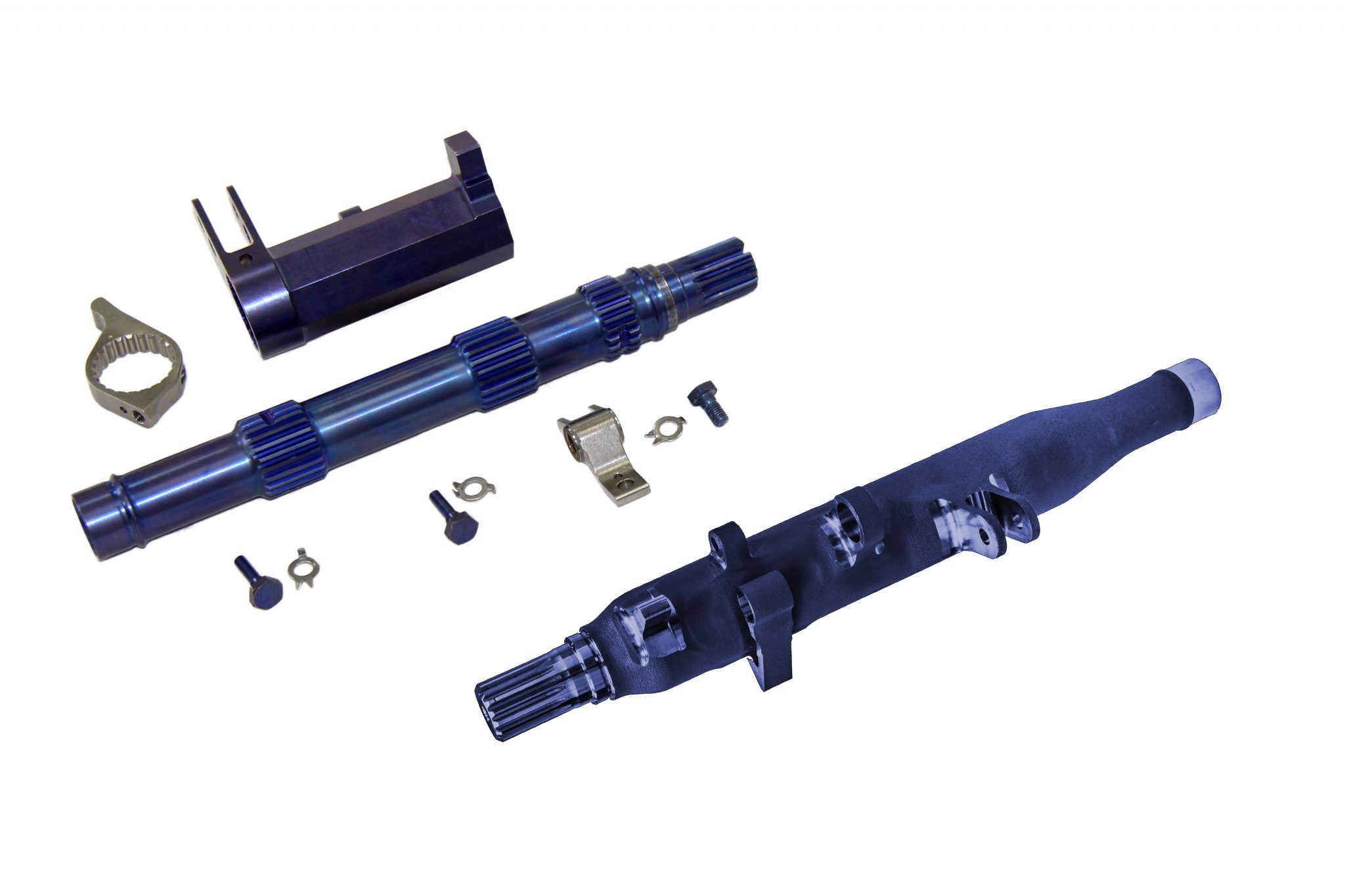

Metal 3D printed helicopter latch shafts

With the EOS M 400-4’s four laser beam system, Airbus Helicopters are able to produce latch shafts 45% lighter and 25% cheaper than its conventional counterpart. The titanium powder used within laser sintering technology, also allows the parts to be created from much less material while maintaining the sturdiness of the original component. The company is also preparing to produce a larger group of A350 door components using 3D printing.

Furthermore, the EOS system can manufacture up to 28 latch shafts in just a single printing process. Considering that each A350 aircraft requires 16 latch shafts, producing these parts using 3D printing leads to a saving of just over four kilos per aircraft, according to Airbus Helicopters.

“Our systems provide a very high and reproducible quality. With this machine performance and with our know-how we can significantly support Airbus Helicopters in the certification process for the component,” said Nikolai Zaepernick, Senior Vice President Central Europe with EOS.

Once production is fully operational, Airbus Helicopters intends to deliver 2,200 components per year. In addition, qualification is scheduled to be completed at the end of this year with serial production starting in early 2019. Moreover, the first A350 components – with serial number 420 – are expected to “take to the skies” in 2020.

Airbus further integrates 3D printed aircraft components

Last year, Airbus installed 3D printed titanium brackets on its in-series production A350 XWB aircraft. Prior to this, the Airbus announced that this aircraft contained over 1,000 3D printed parts on board, which demonstrates the progress made from the aerospace pioneer in additive manufacturing. Furthermore, earlier this year, Airbus in partnership with Belgium’s Materialise, developed 3D printed spacer panels for the cabin of Finland’s largest airline, Finnair’s A320 aircraft.

Keep up with Airbus’ progress as well as the latest 3D printing news by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows 3D printed latch components. Photo via Airbus Helicopters.