Based in Baden-Württemberg, Germany, One Click Metal, is aiming to make metal additive manufacturing more accessible with the introduction of a low-cost Laser Powder Bed Fusion (LPBF) 3D printer.

Set to debut at Formnext, on the 19th of November, the system is designed to be uncomplicated, transparent, intuitive. Speaking to 3D Printing Industry Björn Ullmann, co-founder, and CEO of One Click Metal explained, “Currently you pay around a quarter to half a million in euros per machine and we’re trying to cut that cost significantly.”

“Our main focus is getting the technology out there and enabling as many people as possible because it’s basically limited to aerospace, medical and industries where money basically doesn’t matter.”

Accessible metal additive manufacturing

Entering the market this year, One Click Metal is a spin-off from TRUMPF, the German machine tool manufacturer. The start-up’s founders, Ullmann and Stefan Weber, who also acts as One Click Metal’s CTO, identified the practicality of accessing an industrial metal 3D printer for personal projects. Thus, the partners pursued this idea further and developed a prototype that could be utilized in “one’s own basement.”

With a background in development engineering for additive manufacturing and mechatronics, the co-founders designed the system to be adaptable to open format data, and appropriate for prototyping rather than series production. As a result, the company is positioning itself as an affordable solution suitable for newcomers adopting industrial 3D printing technology as well as SMEs.

“We believe that there are a lot of great minded people out there that would never get access to this sort of technology at the price point it’s at right now,” stated Ullmann. “Therefore, we want to stay at around €50,000 for the printer.” According to Ullmann, this price range decreases the cost of comparable systems by a factor of five. The company also plans to stay under €100 per kilogram of material for its powder, which can be recycled using its system overflow bin.

The One Click Metal 3D printer

A powder cartridge system and unpacking station are offered by One Click Metal, compactly combining four normally detached steps. This is intended to provide educational institutions with the necessary security for students and trainees to operate the system. Currently, the machine can process stainless steel into parts with a density greater than 99.5%. Soon, the company plans to add aluminum and tool steel to its material portfolio.

As stated by Ullmann, the laser is the most expensive part of a metal 3D printer. By creating its own laser, which offers a different wavelength, the 3D printer’s cost was reduced. “We worked really hard on getting a very cheap but fairly good laser source developed which offers the same energy level as others – and that is basically our voodoo,” Ullmann concludes.

Visitors to Formnext can find One Click Metal in hall 11, Level 0, at booth E71 from November 19 – 22nd. Visit One Click Metal for more information.

You can keep up with additive manufacturing news by subscribing to the 3D Printing Industry newsletter, following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

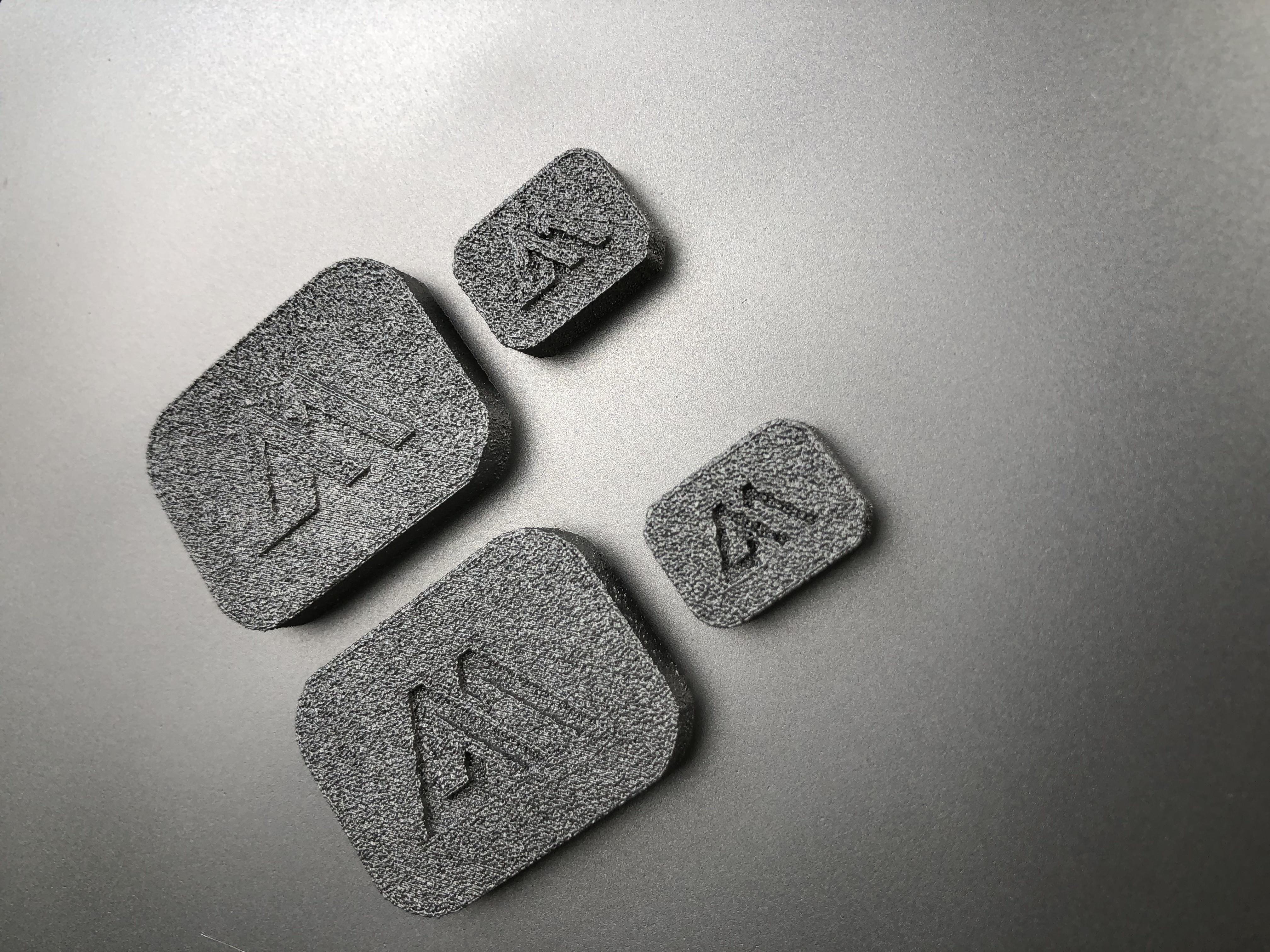

Featured image shows 3D printed parts from One Click Metal. Photo via One Click Metal.