Stratasys Direct Manufacturing held a media summit at its Austin, Texas headquarters earlier this year, and they have produced an interesting 3D printing study using information gathered directly from professional users. I was lucky enough to go to the facility, sign a few NDAs, and check it out. They had a cool EOS 800 Sint system, which are pretty rare; they can print material from PEEK and PEKK materials. I was also surprised at the amount of finishing services Stratasys Direct Manufacturing offers.

The study, produced by SMS Research Advisors focused on additive processes and their impact on manufacturing. 3D printing professionals in all fields were surveyed – designers, engineers, executives, and managers – and the results were printed in the study entitled 3D Printing’s Imminent Impact on Manufacturing.

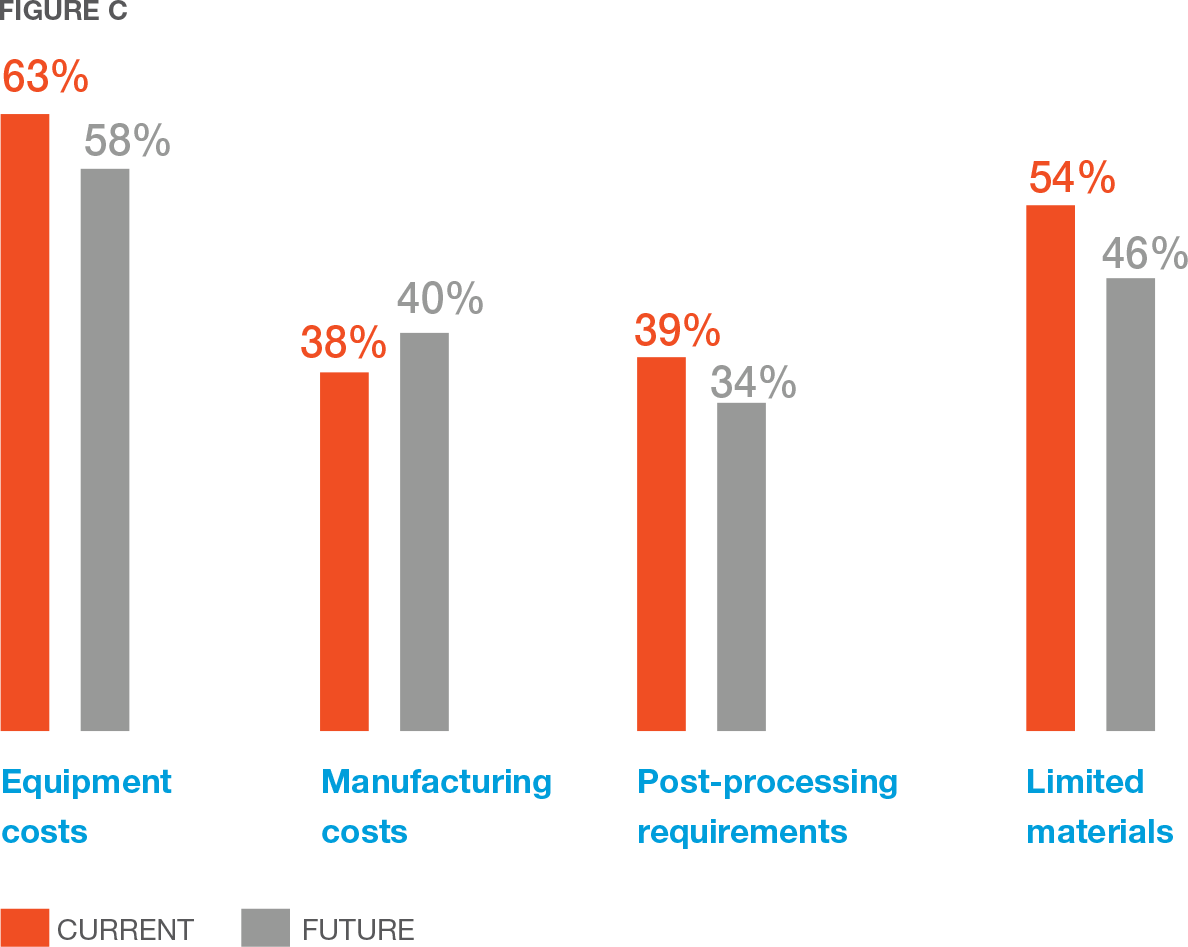

40% of the professionals surveyed are employed by top earning, 3D printing-committed companies, with annual revenues of $50 million and over. The study offers a unique insight into the current trends and future implications of 3D printing by uncovering the motivations behind the industry’s most dedicated users. “We needed to look beyond our factory walls to get a more complete sense of where 3D printing is headed, so we turned to those who live and breathe the technology just like we do – professional users,” said Joe Allison, CEO of Stratasys Direct Manufacturing. “We set out to uncover the common themes among companies who are on the spectrum of larger-scale adoption and integration of 3D printing into their manufacturing process. We’re sharing our findings to help advance adoption and help manufacturers’ maximize the business benefits.”

Mr. Allison had this to add about the results of the study, “If your company is a committed user of 3D printing, the report will provide assurance that you are headed down a similar path of your peers and face many of the same challenges to adoption. If you’re still dipping your toe in the water, the results may serve as a wake-up call to take swifter action.”

One of the most interesting findings lends credence to the call for swifter action: additive metal use in manufacturing is expected to double over the next 3 years. Other notable findings have to do with the future of AM sourcing, with 36% of those surveyed believing that Energy and Consumer industries will likely outsource their AM, while the Aerospace and Medical industries will likely grow their in-house AM. Full details of the report can be downloaded for free here.