This digest of 3D printing news, features Lockheed Martin, Harford Community College, Jesse Garant Metrology Center, MakerBot, America Makes, SLM Solutions, DisTech Automation, Leapfrog, Formlabs, Porsche, and Duke University.

Lockheed Martin funds $1 million advanced manufacturing center

Denver’s Metropolitan State University (MSU Denver) has recently been aided by a $1 million donation from defense and aerospace company Lockheed Martin. The funding will be spread over the next four years to support manufacturing at the Lockheed Martin Additive Manufacturing Laboratory which is located in the newly built Aerospace and Engineering Sciences Building at MSU Denver.

Lockheed Martin’s Space Systems division (LMSS) is headquartered nearby and will support the fabrication of aerospace parts. Brian O’Connor, LMSS president of production operation explains the benefit of learning about the technology,

Emerging manufacturing technologies will create possibilities we can only dream of today, like printing an entire satellite from the ground up or printing complex parts that we can’t machine using traditional methods. We’re helping students design with those new concepts in mind so the next space missions are innovative, affordable and faster to market.

Harford Community College awarded grant for Additive Manufacturing Technician Program

Over in Maryland, Harford Community College has been awarded a $200,000 grant for Advanced Technological Education (ATE) from the National Science Foundation.

The funding will be used to create an additive manufacturing career pathway at the college to cater the growing market in Northeastern Maryland with partnerships between industrial companies.

Jesse Garant Metrology Center to invest $15 million in CT, X-Ray, 3D Scanning Technology

Canadian part inspection company Jesse Garent Metrology Center has committed to a $15 million investment for part inspection systems as a result of a growing demand from the additive manufacturing industry.

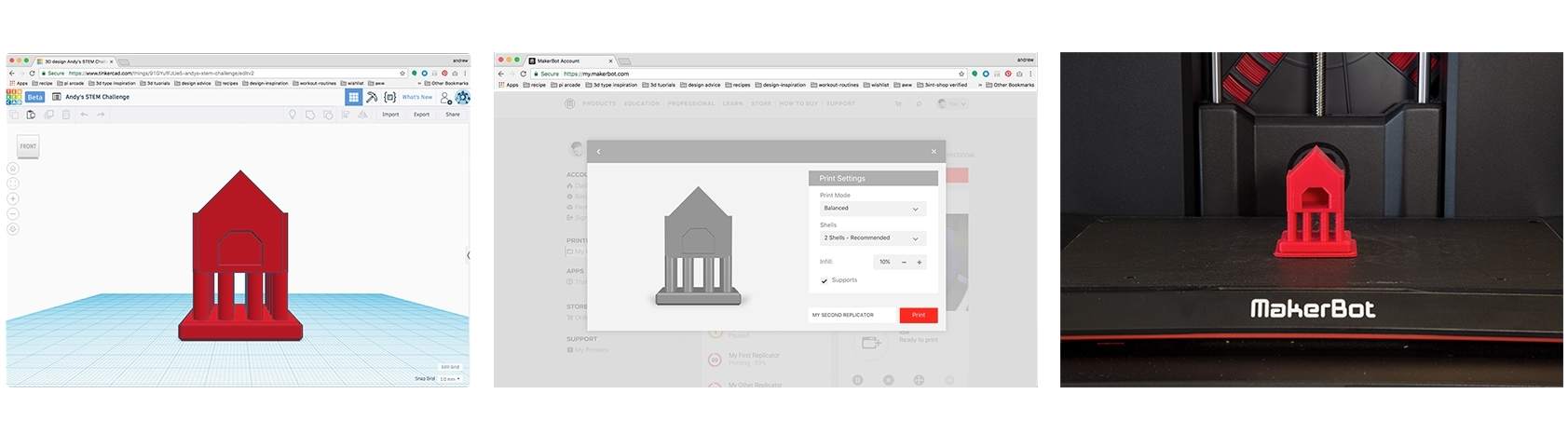

MakerBot launches ‘My MakerBot’ education platform

Desktop 3D printer company MakerBot has announced the launch of an education platform catered to the chromebook – My MakerBot. The platform is intended to allow school children to start and monitor 3D prints using chromebooks. Nadav Goshen, CEO of MakerBot explains,

…this development is part of our continued focus on customers needs, and is at the core of our efforts in education to dramatically improve student access to 3D printers. As more and more districts adopt Chromebooks and rely on web-based apps, 3D printers are being implemented in those same classrooms – making fully connected, cloud-based 3D printing more important than ever for both teachers and students.

In addition, MakerBot has announced the platform will also benefit from Tinkercad integration. The system will be available in the coming weeks so ready in time for the start of the next academic school year.

Polar Cloud integrates Tinkercad

North Americans Polar 3D has announced it is integrating with Tinkercad so users can send designs straight from the design software to 3D print over the Polar Cloud. Greg LaLonde similarly cites education as a contributing factor to the announcement as he says,

Providing students with a digital design and manufacturing experience is project based learning at its finest and will help develop a pipeline of future talent in additive technologies. Our goal is for the Polar Cloud to make digital manufacturing universally accessible where anyone with a browser can learn, design and ‘make’ regardless of their economic, political or social condition.

America Makes asks for 3D printing education tools

U.S additive manufacturing imitative America Makes is requesting educational content as part of its InnoCentive program. The aim is to support education in this field and subsequent adoption of the technology.

For more details, check out the Innovation Sprint: Additive Manufacturing Curricula Challenge page.

SLM Solutions announces new HQ building

German metal 3D printer manufacturers SLM Solutions has announced it will move into a new headquarters that enables production up to 500 machines a year. SLM Solutions received 128 orders in 2016 for its metal 3D printers which was an increase of 28 from the year prior.

The new building is expected to be completed by early 2018 with the move expected to occur in Q1. Adding to the new machine production capacity, SLM will also be able to house 150 more employees from the current number of 350.

DisTech Automation launches E3D V6 hot end add-on Prometheus

Ontario-based 3D printing company DisTech Automation has released its Prometheus add-on which enables multi-material 3D printing . The system allows printing at up to 300°C.

The idea behind the product is to allow affordable printers to have access to advanced capabilities. The Prometheus initially crowdfunded on Kickstarter raising $76,215 (CAD) in 30 days. The system $269.00 (USD).

Leapfrog releases Bolt Pro

Dutch 3D printer manufacturer Leapfrog has released its Bolt Pro industrial 3D printer. The machine is intended to provide an industrial alternative to the standard Bolt 3D printer and will retail at $7,285. The printer has some advanced features including a 7 inch touchscreen and industrial build chamber. Leapfrog’s CEO, Sander Adam, gave us his insight into the future of 3D printing recently.

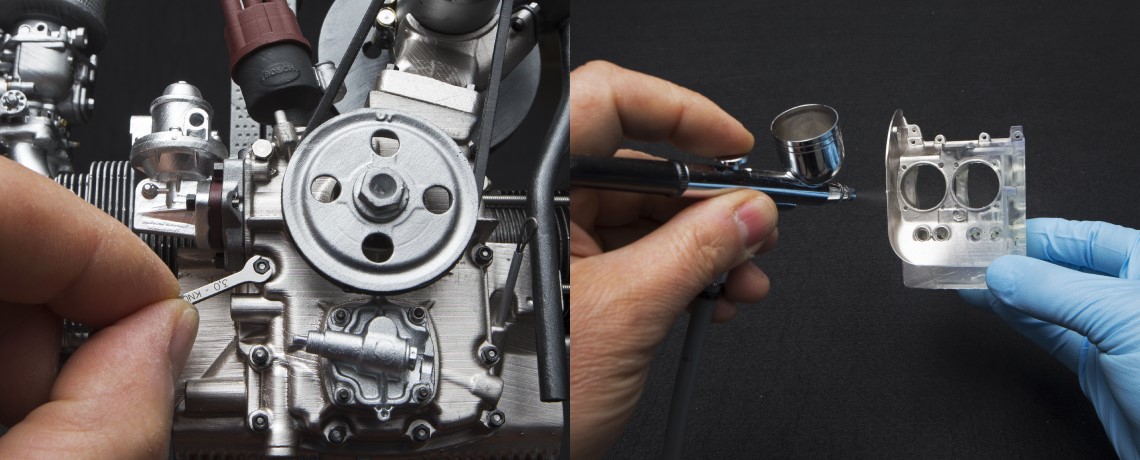

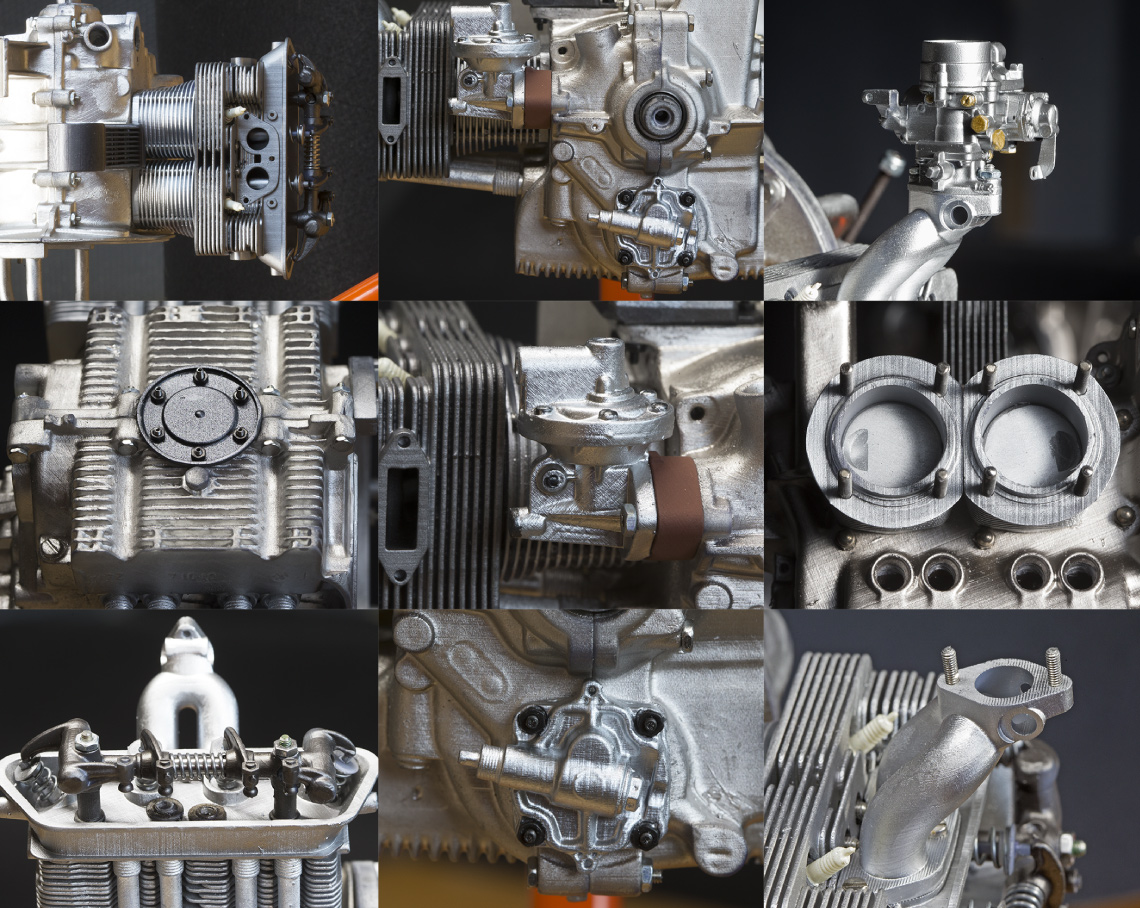

Italian 3D prints scaled Porsche engine

Italian Porsche enthusiast Giuseppe Guerini has used 3D printing to create a scale model of a Porsche engine. His passion began with his first Porsche and he says in total,

I’ve had about sixty altogether and I own three at the moment – 1951, 1952 and 1958 models – as well as engines, spare parts, documentation and so on.

Guerini used a 3D scanner to create a digital model of the engine, remodelled the file with Rhino and then 3D printed the many, many parts with a Formlabs Form 2 SLA printer.

The finished engine is a 1:4 scale replica of a vintage 1952 Porsche 356 and was made from 250 parts. The parts were printed in five different batches which took 45 hours in total.

3D printed Syrian Palmyra Arch of Triumph reaches Italy

The 3D printed Palmyra Arch – created to preserve the historic Syrian monument – is on tour. The 3D printed monument has drawn over 2 million visitors in two days since arriving. The arch could previously be seen on London’s Trafalgar square.

Italian Culture Minister Dario Franceschini spoke at the unveiling,

Considering our own rich heritage and its importance to us, Italy plays a leading global role in issues pertaining to culture. We are looking to translate this strength into action by promoting the concept of cultural diplomacy around the world, and raising awareness around heritage preservation.

LED jacket monitors 3D printer lab

Duke University is often at the forefront of 3D printing research. Now one of Duke’s Innovation Co-Lab users has created an LED jacket to monitor its 3D printers. We recently reported on the Lab’s use of proprietary software to control its array of 3D printers and now the team has taken this one step further by delving into the fashion industry.

The smart jacket allows users to monitor the status of the 3D printers (as long as they’re not the ones wearing it) and for full details on how to create the jacket, visit Sally Hall’s post on Instructables.

3D printed mechanical laser show

Finally, elsewhere in the maker community, Thingiverse user Evan Stanford has created a mechanical laser pen device with his 3D printer. The system enables Evan to project a number of different images by turning the crank.

If you’d like to build the mechanical laser show, the files are available here.

To stay updated with all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows the Sliced logo over the image of Giuseppe Guerini’s 3D printed Porsche engine parts. Image via Creatr.