The month of October 2021 saw the return of the 3D Printing Industry Awards and the winners announced for the Formnext 2021 Start-up Challenge, alongside bioprinting developments, hypersonic weapons, a Thingiverse data breach and plans to build the largest 3D printed neighborhood.

Read on from the standout developments in October, which involved the likes of 3D Systems, the US Navy, ICON, Redwire, Stratasys, Rocket Lab, Thingiverse, and others.

Ramping up the space race

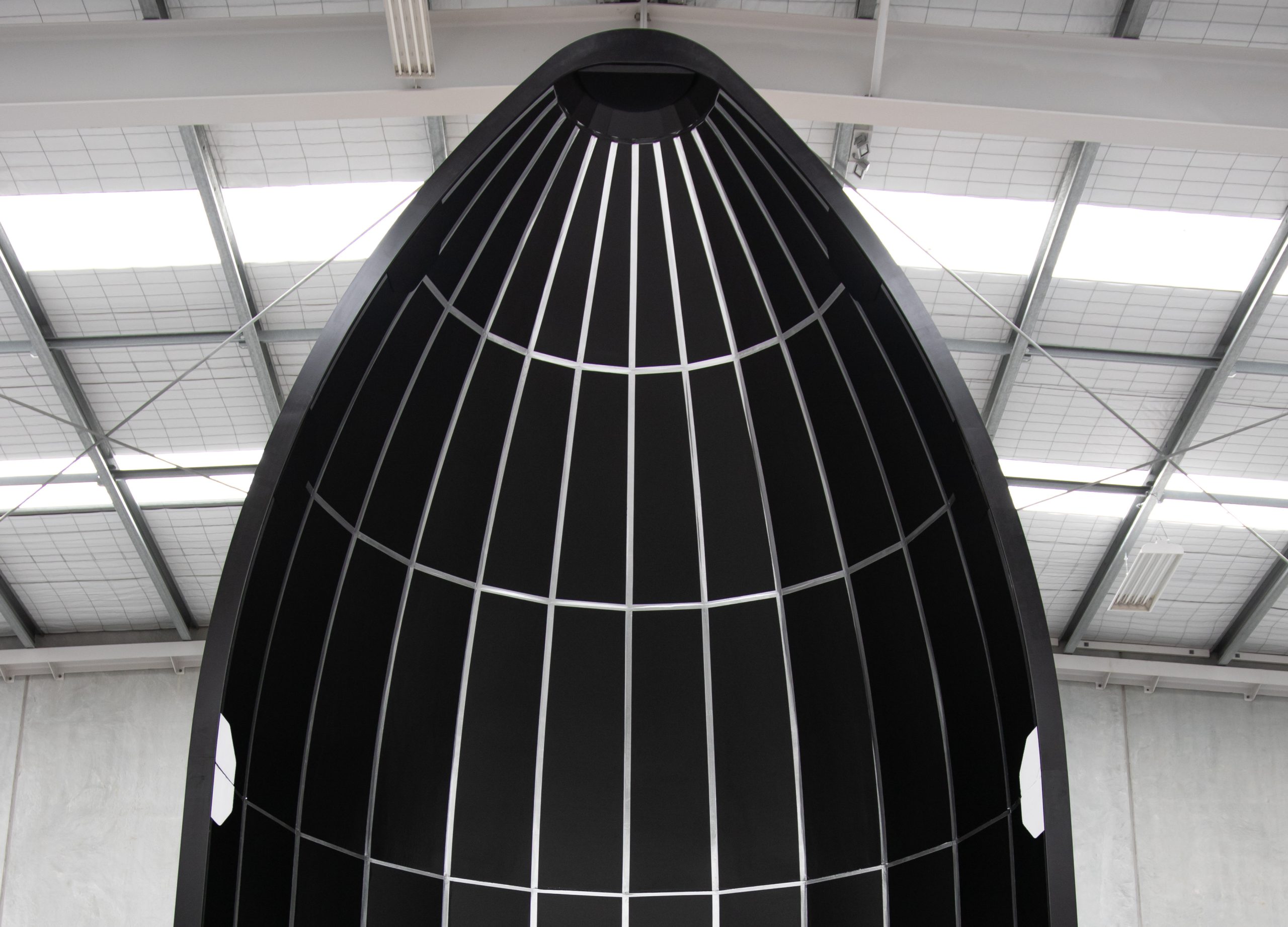

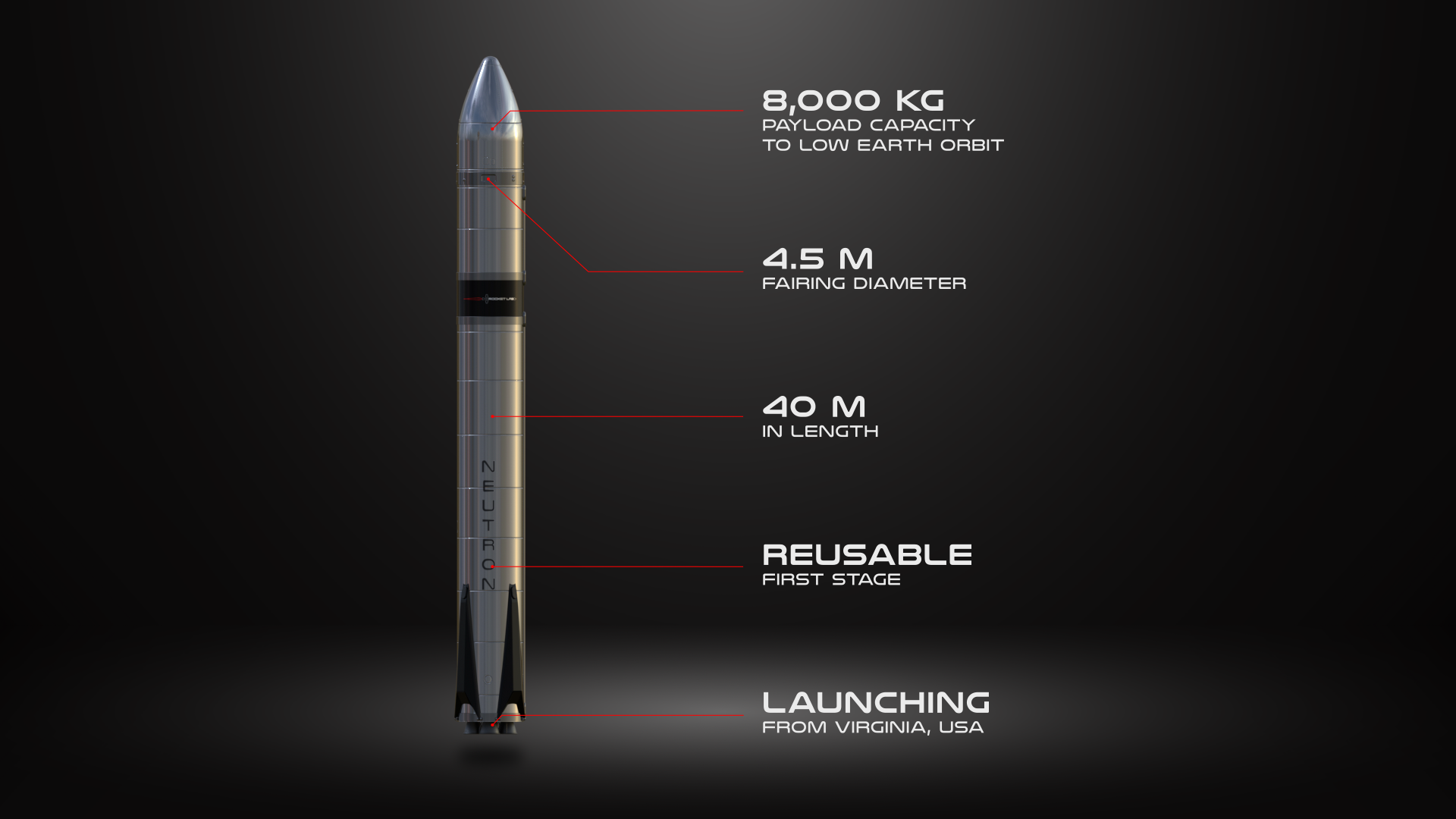

October get underway with the news that California-based aerospace firm Rocket Lab had been awarded $24.35 million by the US Space force to fund the R&D of its next-generation Neutron launch vehicle. Dubbed the “mega constellation launcher” thanks to its 800-kilogram load limit, the Neutron will stand at 40 meters tall and be capable of taking off from an ocean platform once complete, which is expected to be in 2024.

The deal also saw Rocket Lab signal its intent to join the National Security Space Launch (NSSL) program, within which its rocket could be used to launch the USA’s most critical missions from 2025.

“We’re dedicated to building a next-generation rocket that will transform space access for constellations through to the most critical missions in support of national security,” said Peter Beck, CEO of Rocket Lab. “This award is a vote of confidence in the Neutron and our ability to deliver low-cost, responsive, dedicated launches for the US Government.”

Stratasys takes over Xaar 3D

Industrial 3D printer manufacturer Stratasys took full control of inkjet printhead developer Xaar’s High Speed Sintering (HSS) subsidiary Xaar 3D during October, having worked with the firm to integrate Selective Absorption Fusion (SAF) technology into its H Series machines.

According to Stratasys, the move will “accelerate its growth in production-scale 3D printing” due to SAF’s ability to provide manufacturers in the consumer, automotive, and electronics sectors with high-throughput capabilities.

New AM certifications

Meanwhile, Munich-based certification firm TÜV SÜD began offering certifications for additive manufacturing facilities in accordance with the ISO/ASTM 52920 standard, which specifies quality assurance requirements for manufacturers that use 3D printing technologies.

The new standard defined criteria for 3D printing processes, quality-related factors along the process chain, and the sequence of operations conducted at additive manufacturing production sites.

“Using the new standard, component manufacturers can streamline supplier audits to an enormous extent,” said Simon Schlagintweit, Lead Auditor for Additive Manufacturing at TÜV SÜD. “This facilitates the auditing process and ensures the quality of industrial-scale additive manufacturing throughout the supply chain.”

Thingiverse data breach

Midway through the month, digital 3D model repository Thingiverse was reported to have suffered a mass data breach in which the personal information of around 228,000 subscribers was made publicly available online. Although initially leaked in October 2020, data breach notification service provider ‘Have I Been Pwned’ found evidence that the 36-gigabyte data cache was “extensively circulating within the hacking community” in October 2021.

Thingiverse founder Makerbot commented on the breach: “We became aware of and have addressed an internal human error that led to the exposure of some non-sensitive user data for a handful of Thingverse users. We have not identified any suspicious attempts to access Thingiverse accounts, and we encouraged the relevant Thingiverse members to update their passwords as a precautionary measure.

“We apologize for this incident and regret any inconvenience it has caused users. We are committed to protecting our valued stakeholders and assets, through transparency and rigorous security management.”

Formnext Start-up Challenge winners

October also saw the winners announced for the 2021 Formnext Start-up Challenge and AM Ventures Impact Award. The Start-up Challenge pits young 3D printing enterprises against each other based on their novel business ideas and technological achievements, while the AM Ventures Impact Award recognizes the positive social and environmental impacts that 3D printing innovation can have.

The five winners of the 2021 Start-up Challenge were: Atlant 3D Nanosystems, which is developing a platform for printing micro and nanoscale multi-material parts; Azul 3D, the company behind the High Area Rapid Printing (HARP) 3D printing technology; Nobula, which is developing a novel desktop 3D printer capable of producing parts made of glass; Fited, which is working on a new 3D printed medical device for treating spinal deformities; and Print Parts, whose digital signature technology can make 3D printed parts scannable, serialized, and cloud-connected.

The winner of this year’s AM Ventures Impact Award was medical device manufacturer Vispala Technologies, which has been using 3D printing to produce affordable and aesthetic prosthetics, orthotics, and assistive robots for those in need since 2018.

Open-source machine learning

Engineers at the Massachusetts Institute of Technology (MIT) developed an open-source machine learning algorithm with the potential to expedite the process of identifying 3D printable materials. The algorithm can automatically identify viable 3D printing materials with desired qualities such as rigidity, compressive strength, and toughness, therefore reducing the cost, lead times, and waste incurred during traditional resin formulation.

“Materials development is still very much a manual process,” said Mike Foshey, the paper’s co-lead author. “A chemist goes into a lab, mixes ingredients by hand, makes samples, tests them and comes to a final formulation.

“But rather than having a chemist who can only do a couple of iterations over a span of days, our system can do hundreds of iterations over the same time span.”

New bioprinting patents

The month of October saw 3D bioprinting firm BICO issued two new patents for the bioprinting of temperature-sensitive bioinks, an achievement the firm says will expedite R&D for applications such as 3D cell-based drug development, tissue engineering, and disease modeling.

The first patent, US 11,046,001, was granted in the US and defined a proprietary print bed design with temperature regulation capabilities for precise control of the gelation process, while the second patent, SE 543880, was granted in Sweden and covered the controlling of the cartridge and nozzle temperature in 3D bioprinters.

According to BICO, the new patents will be integral in bioprinting both collagen and gelatin-based bioinks for more precise temperature control and the avoidance of nozzle clogging.

The return of the 3D Printing Industry Awards

The 3D Printing Industry Awards returned in full force in October 2021 to highlight and champion the outstanding companies and people in our industry, watched by over 4,000 people on our YouTube channel.

As ever, the awards were hotly contested, with over 140,000 votes received on the shortlists. The winners included 3D Systems (Innovation of the Year), the Satchi-Fainaro Lab at Tel Aviv University (Medical, Dental or Healthcare Application), Fishy Filaments (TÜV SÜD Sustainability in Additive Manufacturing), Slice Engineering (Start-up of the Year) and America Makes’ Ralph Resnick (Outstanding Contribution to 3D Printing).

A full list of the winners and their reactions can be found here, and you can watch the replay of the 2021 3D Printing Industry Awards livestream here.

3D printing on the Orbital Reef

Elsewhere, Space system manufacturer Redwire unveiled its plans to deploy 3D printing onboard the upcoming commercial space station known as the “Orbital Reef”. The firm will contribute to the mission’s microgravity R&D and manufacturing activities, which could see a spacefaring business park enter operation in Low Earth Orbit (LEO) by 2026.

The Orbital Reef’s main module will be built and launched by Blue Origin, a company with extensive 3D printing experience, and will enable Redwire to further the research it has started on the International Space Station (ISS) in order to make new scientific discoveries.

“The Orbital Reef represents the next evolution of the commercial space paradigm by creating the first-ever crewed private sector platform in LEO,” said Redwire’s Mike Gold. “The Orbital Reef will carry forward the singular legacy of the ISS, supporting innovative microgravity research, development, and manufacturing activities which will advance fields as diverse as communications and biotechnology.”

Largest 3D printed neighborhood

October also saw Texas 3D printing firm ICON reveal plans to build what it says will be the largest community of 3D printed homes to date in Austin, Texas. The company plans to deploy its 3D printing robotics technology, software, and advanced materials to build the homes, which are due to come to fruition next year.

ICON has partnered with architecture firm BIG-Bjarke Ingels Group and leading US homebuilder Lennar for the project, off the back of the latter’s investment in ICON’s recent $207 million financing round.

“Labor and material shortages are two of the biggest factors pushing the dream of homeownership out of reach for many American families,” said Eric Feder, President of LENX, Lenna’s investment arm. “Lennar has always expanded the boundaries of technological innovation to keep quality homes affordable and 3D printing is an immensely encouraging approach.

“We are excited to collaborate with ICON to develop solutions to emerging challenges in the coming years.”

3D printing hypersonic weapons

Moving onto defense now, and the US Naval Surface Warfare Center Dahlgren Division (NSWCDD) announced it will be doubling down on the development of hypersonic missile technology using 3D printing processes.

As part of this aim, Dahlgren has set up partnerships with other Department of Defense (DoD) agencies, industry partners, and academic experts, including the John Hopkins University Extreme Materials Institute and the University of Miami’s 3D printing center.

Bolstering 3D bioprinting

Rounding off October’s highlights is 3D printer manufacturer 3D Systems, which unveiled plans to expand on its bioprinting program after acquiring Volumetric Biotechnologies for $400 million. 3D Systems will leverage the company’s expertise to broaden the applications of its ‘Print to Perfusion’ technology developed with United Therapeutics.

Alongside its focus on 3D bioprinting human lung scaffolds, 3D Systems will now also seek to develop other human organs and vascularized tissues for human non-organ regenerative medicine applications.

“Our work on a vertically-integrated platform for the 3D printing of organ scaffolds followed by cellularization to create fully-compatible human organs, dovetails perfectly with the work being done by 3D Systems and United Therapeutics,” said Jordan Miller of Volumetric Biotechnologies. “Working together, we expect to accelerate these efforts, expanding them beyond lungs to other human organs.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows a render of what the 100-home community will look like at street level. Image via ICON.