In this edition of our 3D printing news digest Sliced, we have news from Blue Origin, Digital Alloys, COBOD, 3D Hubs, and Euspen. Read on to learn more about advanced precision in 3D printing, a home-made 3D printed smartwatch, and rebuilding Notre Dame Cathedral.

The launch of 3D printed end-use parts

Blue Origin, the aerospace company of Amazon CEO Jeff Bezos, has launched a test flight of its 3D printed New Shepard Rocket. The New Shepard was designed and manufactured to carry paid customers to space. This was the 11th test flight of the vehicle and in the next trip it will carry 38 research payloads, including those for 3D printing research in space.

Highlighting the influence of personalities like Bezos, and his contemporaries Elon Musk and Mark Zuckerberg, artist Sebastian Errazuriz has recreated their likeness in an exhibition titled The Beginning of the End. In this work the tycoons, alongside other famous figures Larry Page, Sergey Brin, Edward Snowden, Vladimir Putin, Chinese President Xi Jinping and Donald Trump, are re-imagined as mythological figures. Though appearing to be made of marble, each of the figures is 3D printed out of resin.

The Beginning of the End will run May 1 through 24 at The Elizabeth Collective in New York.

Fitz Frames, a startup form in Ohio, is designing customized eyeglasses for children aged three and up. Using a virtual app, children can try on different glasses and customize the size, color, and shape of the frame. Currently, the price of the frames is $95, with an annual subscription of $185, which allows customers to have as many free replacements as they need in a year. Each pair is 3D printed using SLS technology.

Engineering firm Swiss Scheurer has printed two large parts for the luxury catamaran ‘Moonwave’. The parts are made of carbon fiber composite and will be installed in the rudder bearing system.

VEKA Group, one of the largest manufacturers of PVC-U windows and door systems in the UK, has 3D printed a window frame. The company claims that it is the first 3D printed window in the UK. The window was made on a Blackbelt conveyor belt 3D printer.

Head of Technical at VEKA, Paul Kennington, said, “We invested in this top-of-the-range 3D printing technology because it offers significant benefits for our customers, particularly for prototyping. It means we can create and test the viability of potential new products immediately, for a fraction of the cost associated with traditional prototyping. We can anticipate where efficiencies can be made and solve any potential problems long before we get to the more involved tooling design stage.”

“It has already allowed us to produce numerous prototypes for internal needs and for our customers, including designing and testing a new bottom rail for a customer to add to their door range.”

Going beyond borders

Nanoe, a French 3D printing materials manufacturer, has set up a U.S operation in Youngstown Business Incubator (YBI) while it explores business opportunities in the country. The French company is known for Zetamix a line of metal and ceramic filament and Zetaprint, an FDM/FFF-based metal 3D printer.

Guillaume de Calan, CEO of Nanoe, said, “When we were looking for a footprint in the United States, we were looking for an area with competencies in additive manufacturing and also the ceramic industry […] We had a very good reception here at the YBI and hired our first employee.”

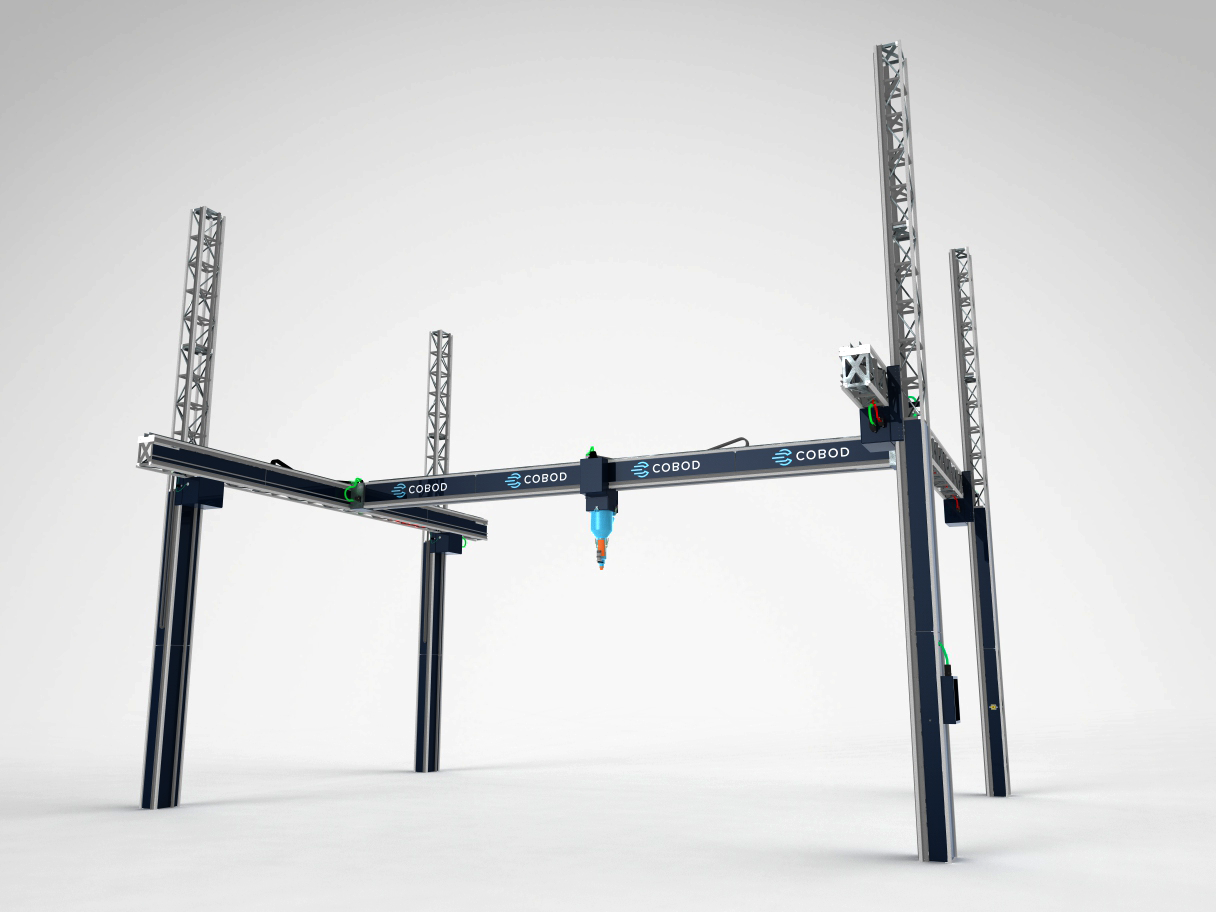

COBOD, a modular construction 3D Printer manufacturer, has won its second European tender, this time awarded by the Technical University of Denmark (DTU). Jakob Lemming Christensen Head of Department of Center for Diploma in Engineering at DTU said, “For DTU, it is key, that the software is easy to understand, such that we can expect that after basic training our students will be capable of running the printer by themselves. Also, the possibility to use any type of concrete and mortar on the printer was determining, as we want to experiment a lot with new recipes. We are therefore thrilled that this seems to be the case for the COBOD printer, where the software is open source, which gives both students and staff a lot of possibilities.”

COBOD was also nominated for 2019 3D Printing Industry Award in the category of the start-up of the year.

Evatronix, a Polish manufacturer of 3D scanners, has moved to expand in the Asian market. The company has signed an agreement with the Japanese 3D scanning solutions provider, OPT Technologies, and Symphony Innovation, a Singapore-based reseller of metrology equipment, active in Malaysia, Thailand, Vietnam, Myanmar, and the Philippines.

Terry Morita, President of OPT Technologies, said, “The 3D solutions offered by Evatronix SA meet the high expectations of companies operating on the Japanese market as regards measurement accuracy and precision […] The eviXscan 3D scanners, in comparison with competitive products, are also attractive in terms of their price.”

Shanghai Union Technology Corporation has discontinued its North American subsidiary. The assets of the subsidiary have now been handed over to the Union Tech Creditors’ Trust.

The Australian government has allotted $50 million to the Manufacturing Modernisation Fund. This money will be used to advance manufacturing technologies such as 3D printing, and other auxiliary technologies like robotics, AI, and automation, as related to Industry 4.0. Karen Andrews, Minister for Industry, Science and Technology, said, “The Coalition Government understands how important manufacturing and manufactured goods are to Australia. About 7 percent of the Australian workforce is employed in manufacturing.”

“We want to make sure that our Australian businesses are able to expand, to tap into global markets because when they do that, they will expand their business here in Australia and they will employ more people.”

CMK Corporation, one of the largest manufacturers of PCBs and electronics in Japan, has acquired a DragonFly Pro 3D printer from Israel’s Nano Dimension. The DragonFly Pro is capable of 3D printing PCBs in conductive and dielectric materials in one step. Gilad Reshef, APAC director at Nano Dimension, “We are thrilled to expand into the innovative Japanese electronics market and look forward to working directly with CMK, a global leader in electronics and PCB technologies.”

3D Hubs, has confirmed that its new North American headquarters will be in Chicago. The money for the new premises was contributed by the company’s recent Series C investment round in March, which successfully closed $18 million. Specifying the location last week, Chicago’s Mayor Rahm Emanuel said, “3D Hubs joins the long list of international companies choosing Chicago for their future.”

“With our growing tech economy and strong digital manufacturing community, Chicago is the perfect home for this innovative company. I look forward to seeing 3D Hubs success in Chicago in the years to come.”

Guyson International, a UK-based manufacturer of finishing equipment, has installed four Euroblast blasting machines system in the factory of Material Solutions, a Siemens business specializing in 3D printing. The Euroblast is used in SLS post-processing to remove unsintered particles from a part. Phil Hatherley, General Manager at Materials Solutions, said, “Materials Solutions has been using Guyson blasters since our origin and when it came to upgrade and update it made perfect sense to us to go back to Guyson […] We have increased size capability plus capacity and working with our team Guyson have provided us with a quality solution for blasting the larger components that our customers are now looking for us to supply.”

In collaboration with the American Society of Precision Engineering (ASPE), Euspen (the European Society for Precision Engineering and Nanotechnology) is planning to hold a meeting of a Specialist Interest Group (SIG) on 16-18 September 2019. The meeting will be held in Ecole Centrale de Nantes, France and the topic of discussion will be advanced precision in additive manufacturing.

And Digital Alloys, a Massachusetts-based 3D printer manufacturer, has published a beginner’s guide to metal powder bed fusion 3D printing. The guide introduces the readers to the fundamentals of powder bed fusion (PBF) such as materials and equipment used, the economic of PBF printing, and design for AM among other topics.

Can 3D printing help Notre Dame?

Hakkasan Group, a global hospitality service based in China, will install the Hakkasan Grid at its hotel MGM Grand Hotel and Casino in Las Vegas, Nevada. The Hakkasan Grid is a 3D printed structure made of kinetic lights.

Fashion designer Julia Daviy has designed a customizable 3D printable skirt made from the recyclable filament and zero-waste methods. Daviy explained, “I started to experiment with 3D printing because I believe that in an age of radical change and global challenges, people need absolutely new clothing […] “Our goal was never to demonstrate the viability of 3D printed clothing and leave things at that […] We’ll have succeeded when beautiful, comfortable, ethically manufactured and environmentally friendly clothes are the standard.”

“Once we’ve brought this technology into the mainstream, we plan to use 3D printing to make smart clothing that integrates technology even further into the design and function of our collection.”

Concr3de, a Dutch construction 3D printing specialist, has proposed the rebuilding of recently fire-damaged Notre Dame Cathedral using 3D printing. To show what is possible the company has 3D printed replacement gargoyle. Eric Geboers co-founder of Concr3de said, “We saw the spire collapse and thought we could propose a way to combine the old materials with new technology to help speed up the reconstruction and make a cathedral that is not simply a copy of the original but rather a cathedral that would show its layered history proudly.”

At the Future Security Forum 2019, U.S. Marine Corps (USMC) Commandant General Robert Neller, said that to improve battle readiness of the U.S military, it is important to continue investing in 3D printing. Speaking to an audience at the Forum, Neller said, “Additive manufacturing is a big deal for us, as an expeditionary force, because if you can make it and you bring it with you, you completely untether yourself from the supply chain.”

3D bioprinting company CELLINK has released two tissue model kits, CELLINK Skin and CELLINK Liver.

And finally, 3D printing enthusiast and maker Samson Leo March showed the community how to make a smartwatch using a 3D printer. The watch was made with the help of open source hardware and software and all the digital files needed to make the watch are available for free on GitHub.

Vote now for the upcoming 2019 3D Printing Awards.

For more news from the 3D printing world, subscribe to our 3D printing newsletter and join us on Facebook and Twitter.

We also have jobs in the industry, visit our 3D Printing Jobs page to learn more.

Featured image shows Sliced logo over a 3D printed gargoyle by Concr3de. Image via Dezeen.