The 2021 3D Printing Industry Awards shortlists are now open for voting. You can watch the event on the 3D Printing Industry YouTube channel on the 21st of October.

BICO (formerly CELLINK), a 3D bioprinting firm, has been issued two new patents for the 3D bioprinting of temperature-sensitive bioinks.

The firm’s recent achievements are ultimately designed to enable higher cell viability and enhanced reproducibility with bioinks such as collagen and gelatin, expediting R&D for applications such as 3D cell-based drug development.

“Our mission at BICO is to create the future of medicine and improve health globally through the convergence of key biotechnologies,” said Erik Gatenholm, CEO and Co-Founder of BICO. “This innovation will help our incredible customers drive advancements across drug discovery, tissue engineering, and disease modeling.”

Two new bioprinting patents

The first of BICO’s new patents, US 11,046,001, was granted in the US. It defines a proprietary print bed design with temperature regulation capabilities for precise control of the gelation process, which is the formation of a viscous gel from a system with polymers. Bioprinted structures made of materials such as collagen and gelatin must go through gelation for 3D printability, making temperature control crucial.

The other patent, SE 543880, was granted in Sweden and covers the controlling of the cartridge and nozzle temperature in 3D bioprinters. According to BICO, this results in greater reproducibility and cell viability, improved printing consistency, reduced downtime due to clogging, and less material waste.

BICO maintains that its new patents will be integral in bioprinting both collagen and gelatin-based bioinks, as these materials rely on precise temperature control to keep cells alive while avoiding nozzle clogging issues. As far as applications go, the former has its uses in bioprinted skin tissue models while the latter has already been researched extensively as a base for hydrogels, enabling robust scaffolds for tissue engineering and regenerative medicine.

“At BICO we work tirelessly to consistently improve and innovate our bioprinting offerings,” adds Dr. Héctor Martínez, co-founder and Chief Technology Officer of BICO. “Our customers around the world are continuously pushing the limits of science using our technology and I’m excited to see how they use these innovations to help make the world a healthier place.”

Taking 3D bioprinting to the next level

At its core, 3D bioprinting provides a route to human tissue model fabrication, helping to advance animal testing-free drug development and (hopefully) eventually serving as a tool for on-demand organ transplants. BICO, through its CELLINK subsidiary and others, already offers an entire portfolio of extrusion-based bioprinters, light-based bioprinters, tissue-specific bioinks, and more. The firm’s products can be found in more than 2,000 laboratories worldwide, including Stanford University, Harvard University, and Johnson & Johnson.

The past year has been a big one for BICO. On top of rebranding, the company has made an effort to acquire several 3D printing businesses in a bid to grow its hold on the bioprinting market. The first of the acquisitions was precision dispensing 3D printing firm Scienion in a deal worth €80 million. The move allowed BICO to incorporating Scienion’s pico and nanoliter cell dispensing capabilities into its product range, expanding its addressable market to the clinical therapeutic industry.

More recently, BICO also acquired in-vitro technology specialist MatTek Corporation for $68 million and two-photon polymerization (2PP) 3D printer manufacturer Nanoscribe for €50 million.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

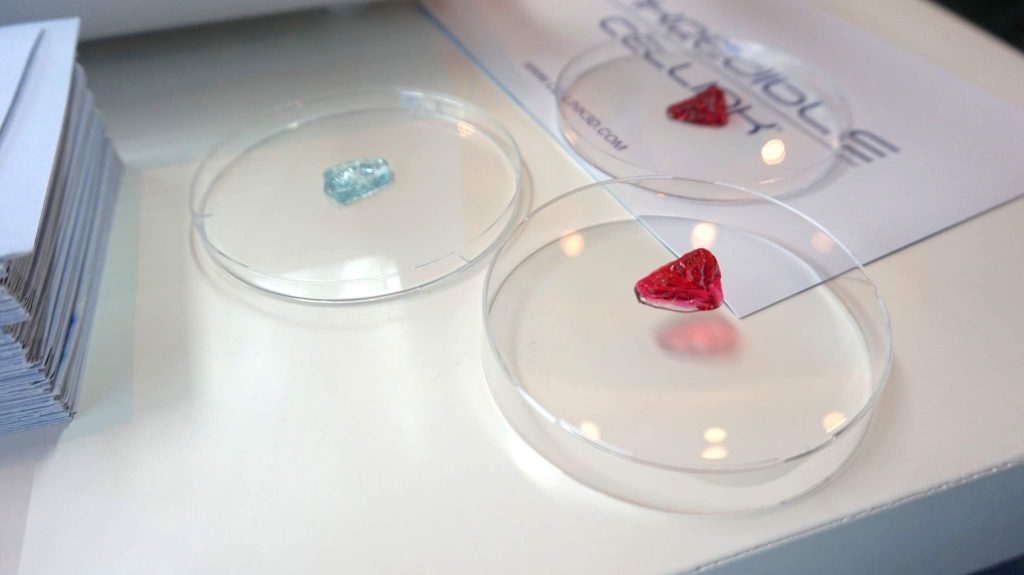

Featured image shows tissue fabrication with BICO’s Bio X 3D bioprinter. Photo via BICO.