Space system manufacturer Redwire has unveiled plans to deploy 3D printing onboard an upcoming commercial space station known as the ‘Orbital Reef.’

Led by Blue Origin and Sierra Space, the project could see a spacefaring business park, complete with cutting edge research facilities, entering operation in Low Earth Orbit (LEO) by 2026. Using the technologies of its Made In Space subsidiary, Redwire aims to contribute to the mission’s microgravity R&D and manufacturing activities, as well as the spaceport’s payload operations and deployable structures.

“For over sixty years, NASA and other space agencies have developed orbital space flight and space habitation, setting us up for commercial business to take off in this decade,” said Brent Sherwood, Senior VP of Advanced Development Programs at Blue Origin. “We will expand access, lower the cost and provide all the services and amenities needed to normalize space flight.”

“A vibrant business ecosystem will grow in LEO, generating new discoveries, new products, new entertainments and global awareness.”

Redwire’s lightspeed start

Since being founded last year by private equity firm AE Industrial Partners, Redwire has rapidly established itself as a major player in the orbital systems supplier segment, via a string of acquisitions. After initially buying aerospace manufacturers Adcole Space and Deep Space Systems in June 2021, the company went on to acquire Made In Space, a firm known for its microgravity 3D printing expertise.

In the past, Made In Space has used its Archinaut low-gravity 3D printing process to create a satellite-mounted ‘virtual telescope’ for cost-effective space research, and worked with Braskem to develop the ‘Braskem Recycler’ which repurposes the ISS’ defunct printed parts, thus its technologies will no doubt be deployed on the new Orbital Reef as well.

More recently, Redwire has made significant advances within its wider business, going public via a $615 million SPAC merger during September, in a move that has seen it raise $175 million in liquid capital. The company continues to make progress with its acquired technologies too, deploying its Ceramic Manufacturing Module to 3D print its first ceramic parts onboard the ISS in December 2020.

Earlier this year, NASA also embarked on an entirely new set of experiments onboard the ISS, including one that has tasked Redwire with determining the feasibility of 3D printing regolith into lunar structures. At the time, the firm’s CTO Michael Snyder said that the project represented a “tech-demo,” which could prove to be “a critical step in developing sustainable manufacturing capabilities for lunar surfaces.”

Privatizing space cohabitation

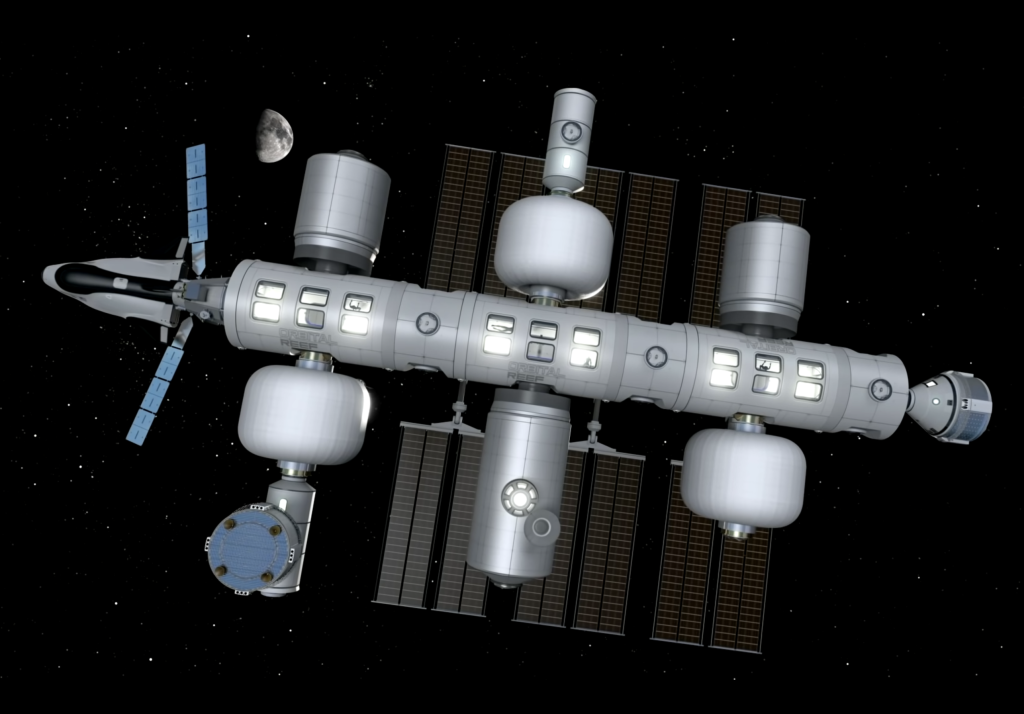

Set to be privately-built, owned and operated, the Orbital Reef is designed to open a new chapter in commercial space exploration, by creating an LEO ecosystem where businesses can thrive. The space dock is expected to not only open new markets to such firms, but allow them to establish their own ‘orbital address,’ from which they can offer research, manufacturing or tourist-related services.

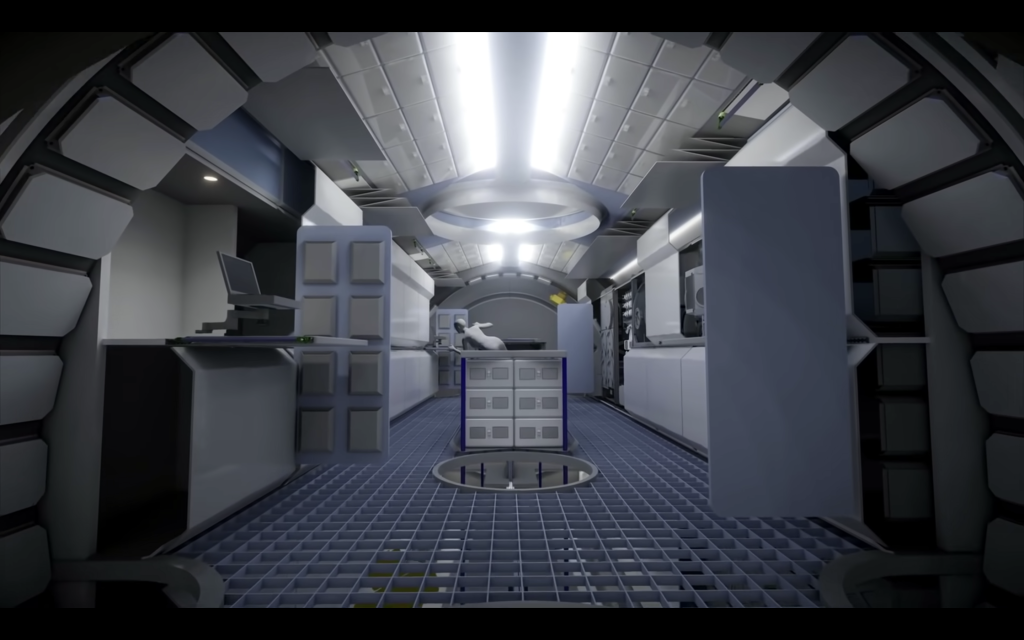

In practise, the port is set to operate as a ‘mixed-use business park,’ with its facilities shared among various tenant firms, in a way that best enables them to scale their activities. With built-in vehicle ports, utilities and amenities, which are designed to grow in-line with demand for the station’s services, the Orbital Reef is expected to attract clients ranging from high-tech firms to nations without space programs.

Given the spaceport’s commercial underpinnings, it will also unsurprisingly be built with cost-effectiveness in mind, and it will offer users end-to-end services covering transportation, logistics, habitation, equipment, accommodation and (if required) an onboard crew, providing them with a more affordable means of accessing space travel or research.

“This is exciting for us because this project does not duplicate the immensely successful and enduring International Space Station (ISS), but rather goes a step further to fulfill a unique position in LEO where it can serve a diverse array of companies,” said John Mulholland, Boeing VP and Program Manager for the ISS. “It calls for the same kind of expertise we used to first design and then build the ISS.”

AM onboard the Orbital Reef

Scheduled to be operational by the second half of this decade, the Orbital Reef’s main module will be built and launched by Blue Origin, a company with extensive 3D printing experience. In terms of the port’s other core section, Sierra Space is expected to deploy its inflatable Life Integrated Flexible Environment (LIFE) module in the project, while its Dream Chaser craft will provide goods transportation.

Finally, the Orbital Reef’s third main module, which is set to be dedicated to scientific research, will be provided by Boeing. Having earlier built the Destiny laboratory module for the ISS, the company now intends to deploy its upcoming Starliner spacecraft to ferry crews and cargo to the station, and help operate the facility once it’s up and running.

For its part, Redwire is currently engaged in microgravity 3D printing R&D on the ISS, and it has previously developed roll-out solar arrays, designed to augment the station’s electricity producing infrastructure. Onboard the Orbital Reef, Redwire is now expected to further the research it started on the ISS, and the port’s facilities could provide it with the platform needed to make new scientific discoveries.

“The Orbital Reef represents the next evolution of the commercial space paradigm by creating the first ever crewed private sector platform in LEO,” said Redwire’s Mike Gold. “The Orbital Reef will carry forward the singular legacy of the ISS, supporting innovative microgravity research, development, and manufacturing activities which will advance fields as diverse as communications and biotechnology.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the upcoming Orbital Reef commercial space station. Image via Blue Origin.