Interested in reading more about the year’s biggest 3D printing news? You can access our full 3D Printing Industry Review of the Year series here.

As is the case every November, our pages were dominated by the Formnext 3D printing news from Frankfurt.

That said, away from the show, the month saw the unveiling of innovative approaches to tackling manufacturing sustainability and part predictability, as well as use case-widening functional material launches. Elsewhere, the impacts of the war in Ukraine and COVID-19 also prevented many from getting sales over the line by the end of Q3, and some even struggled to the point that they went bust.

Read on for more from the likes of Carima, Stratasys, Lattice Medical, Hexagon, Raytheon Technologies, Desktop Metal, Fast Radius, EOS, Siemens, Nexa3D, and Equispheres.

All the news from Formnext 2022

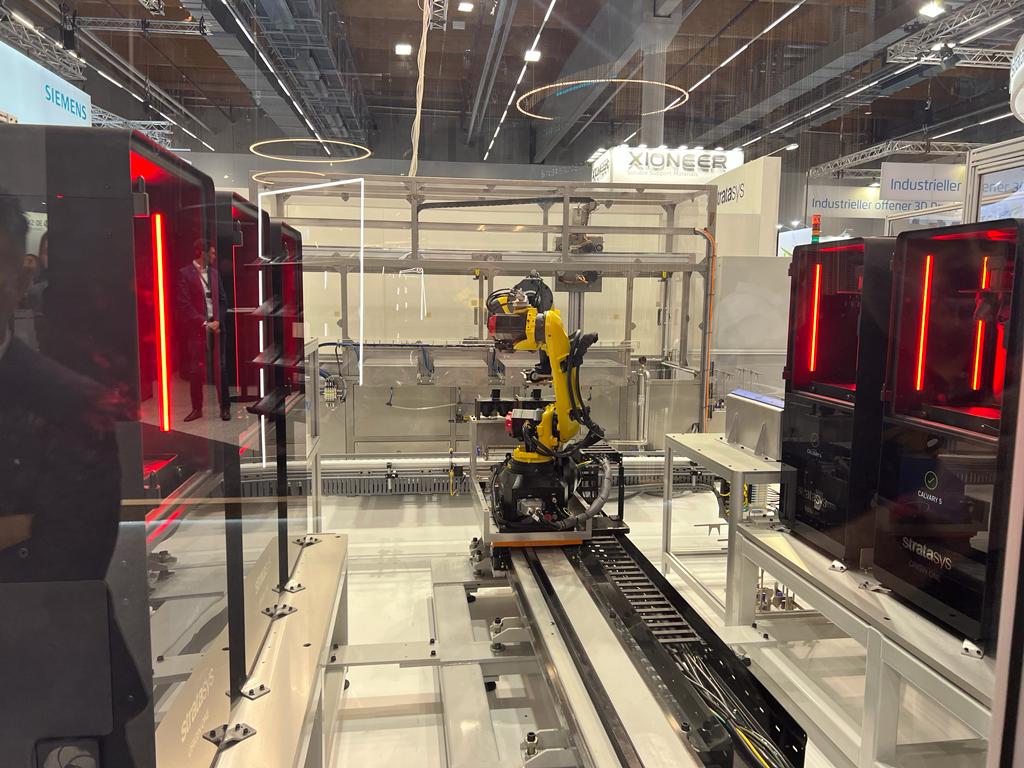

As always, 3D Printing Industry was in Frankfurt, to cover all the latest Formnext announcements live from the show floor. At the show, Stratasys’ P3 Automated Production Cell was certainly one of the more eye-catching exhibits. Comprising a string of Origin One systems, as well as robotics, conveyors and part-finishing equipment, the set-up allowed for the automation and scaling of P3 3D printing.

On the resin additive manufacturing side of the show, Carima also showcased its DM400 DLP 3D printer, a system it markets as the largest of its kind in the world. Powered by the firm’s Carima Continuous Additive Technology (C-CAT) process, the machine is said to have gained significant traction in the dental, automotive and medical industries.

In keeping with one of the event’s time-honored traditions, the Formnext Start-up Challenge returned to provide a platform for the most promising emerging businesses in the sector. Having been named a contest winner, Lattice Medical, told 3D Printing Industry that it aims to “extend the use of 3D Printing in the medical industry” via its materials and services.

The traditional Rave til AM opening night party also returned. See the AM ravers at Formnext Rave til AM party pictures here.

Missed any Formnext 3D printing news? Visit the link.

Advancing functional materials

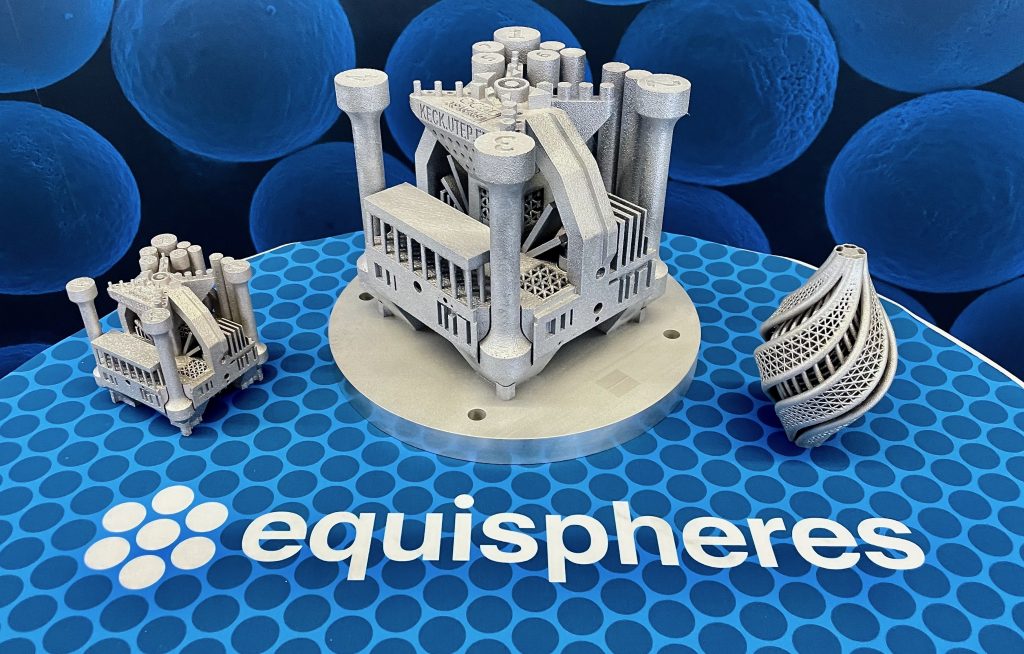

One trend that emerged throughout 2022 and resurfaced at Formnext, was the growing number of functional materials being brought to market to unlock new applications for existing technologies. Equispheres introduced a non-explosible 3D printing aluminum at the show, which is less susceptible to explosions or fires.

At launch, the firm said its powder “reduces the hazards of day-to-day handling without sacrificing the quality of the printed part,” in a way that could effectively lower one of the barriers to deploying 3D printing in industrialized settings.

Nexa3D’s new ESD-safe resin was also said to unlock applications, only in the 3D printing of static-dissipative parts made from plastic instead. Known as ‘Nexa3D xESD,’ the material is designed to offer fundamental static-dissipative performance and isotropic mechanical properties, both of which are understood to be crucial in the electronics manufacturing industry.

Simulation key to part predictability?

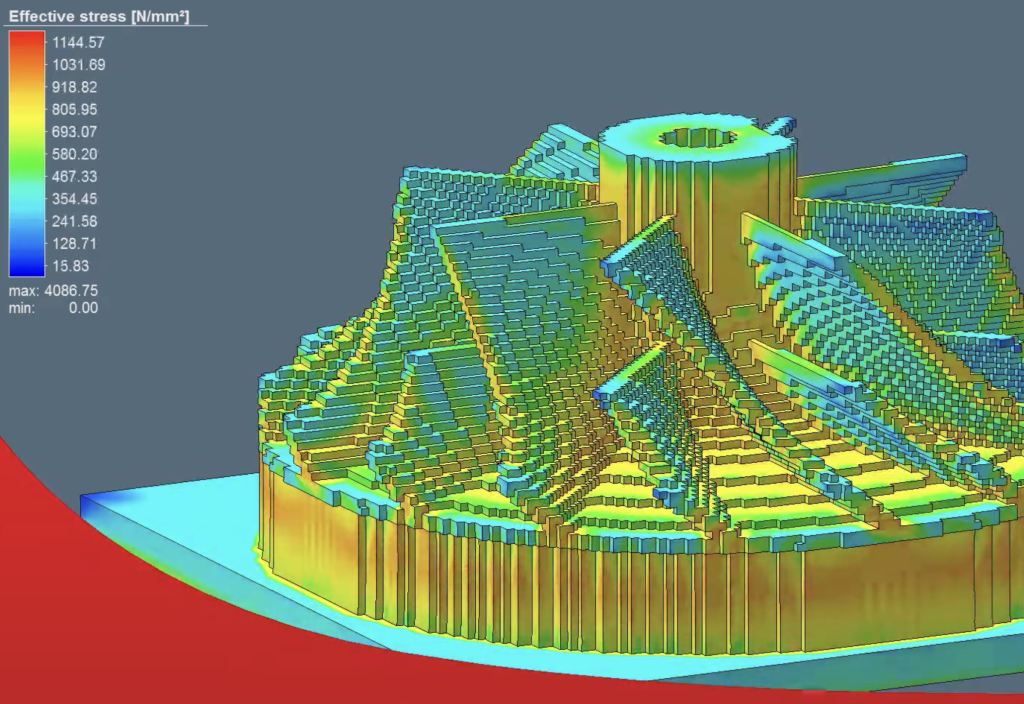

During November, Swedish software developer Hexagon found itself at the center of the drive towards part predictability in additive manufacturing. Not only was it announced that Hexagon had partnered with Raytheon to develop a software for predicting metal 3D printing defects, but it was revealed that the firm had worked alongside Stratasys to unlock PEKK’s 3D printing potential in aerospace.

As part of the latter project, the companies developed a means of modeling exactly how parts 3D printed from Stratasys’ reinforced PEKK materials will behave before they are ever manufactured. With further development, it was thought their approach could make it easier for engineers to take advantage of lightweighting and sustainability opportunities in aerospace, where such validation is vital.

The unveiling of these programs was later followed by the launch of Markforged’s Simulation features for Eiger. Leveraging the new software functionality, users are now able to replace the design-print-break test cycle with virtual testing.

Plotting a course towards sustainability

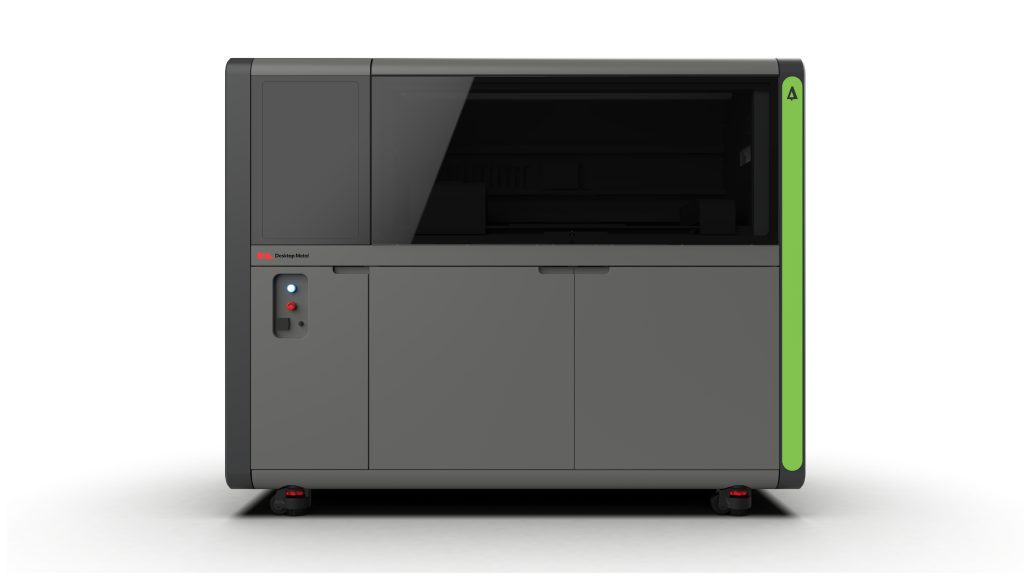

While sustainability continues to be a buzzword in 3D printing, questions remain about the true eco-friendliness of the technology. One firm seeking to address this is Desktop Metal, which launched its Forust Shop System in November. Capable of turning upcycled sawdust into functional, end-use wooden parts, the technology behind the machine was only previously available to customers as a service.

Others, like Siemens, demonstrated how it’s possible to reduce the footprint of robotic grippers usign 3D printing. In fact, utilizing its NX for AM digital process chain and Product Carbon Footprint Calculator, the company found it possible to cut the mass of such parts by 64% in a way that slashed its cost by 73% and carbon footprint by 82%.

At the show, two new eco-friendly EOS 3D printing materials were also introduced. Though traditionally petrol-based, the firm’s PA 2200 has been revamped so that it contains nearly 45% less CO2 than before. With its new climate-neutral PA 1101, on the other hand, EOS claims to have brought a bio-based material to market that doesn’t compromise on quality.

Advances offset by challenging climate

Despite the general positivity surrounding the future growth of the 3D printing sector, the short-term funding and supply headwinds caused by the pandemic and Russia’s war in Ukraine continued to impact many industry firms.

Desktop Metal’s Q3 2022 financials, for instance, came in well below expectations, as its revenue fell 18.4% on a sequential quarterly basis. On the firm’s earnings call, its CFO Jason Cole explained that it had missed internal revenue targets, due to “customers delaying purchases” amid an “uncertain macroeconomic backdrop.” This dip followed a difficult year for the firm. Desktop Metal laid off 12% of its workforce in June 2022, as part of its efforts to progress towards profitability.

Elsewhere in the sector, Fast Radius filed for bankruptcy. Though the company’s assets were later acquired by Sybridge Technologies, who committed to keeping the brand and offering contracts to employees, its collapse after a SPAC merger fueled those who were previously critical of a perceived SPAC frenzy.

2022: 3D Printing Industry review of trends and news

2021: 3D Printing Industry review of trends and news

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows escalators at Formnext 2022 in Frankfurt, Germany. Photo by 3D Printing Industry.