Industrial 3D printer manufacturer Desktop Metal has announced the launch of a wood-based binder jetting version of its Shop System.

Based around a technology developed by its Forust subsidiary, the firm’s Shop System Forust Edition, is capable of turning upcycled sawdust into functional, end-use wooden parts. Though it was first unveiled last year, Desktop Metal has since refined the process, and it’s now being marketed in the form of turnkey systems, with potential architecture, design, consumer and automotive applications.

“Our new Shop System Forust Edition makes it easy to create custom and complex wood designs with a 3D printer on-demand, circumventing supply chain challenges and delivering all-new design possibilities,” said Ric Fulop, Founder and CEO of Desktop Metal. “We believe this concept has the ability to deliver a meaningful sustainability impact and expand to other powdered waste materials over time.”

Disrupting woodworking with Forust

Introduced to great fanfare last year, Forust technology is designed to make wood 3D printing affordable, reliable and sustainable. One of the ways it does so is by using upscaled waste from the wood manufacturing and paper industries as a feedstock. This, the Desktop Metal subsidiary says, will be key in the drive towards net-zero, ‘additive rematerialization’ and building a more sustainable future.

At first, the technology was launched solely in the form of an online store, through which clients could order custom parts. However, having optimized the process with beta users, Desktop Metal is now bringing it to market via a fully-fledged machine, shipped with a comprehensive post-processing guide to help adopters create the best possible circular wood-based builds.

“One of the great things about binder jet 3D printing technology is it can transform virtually any powder material into functional, end-use parts,” added Fulop. “Beginning with an ample supply of sawdust byproduct from the traditional wood milling industry, we are using our technology to build cradle-to-cradle manufacturing for wood.”

Taking Forust technology to market

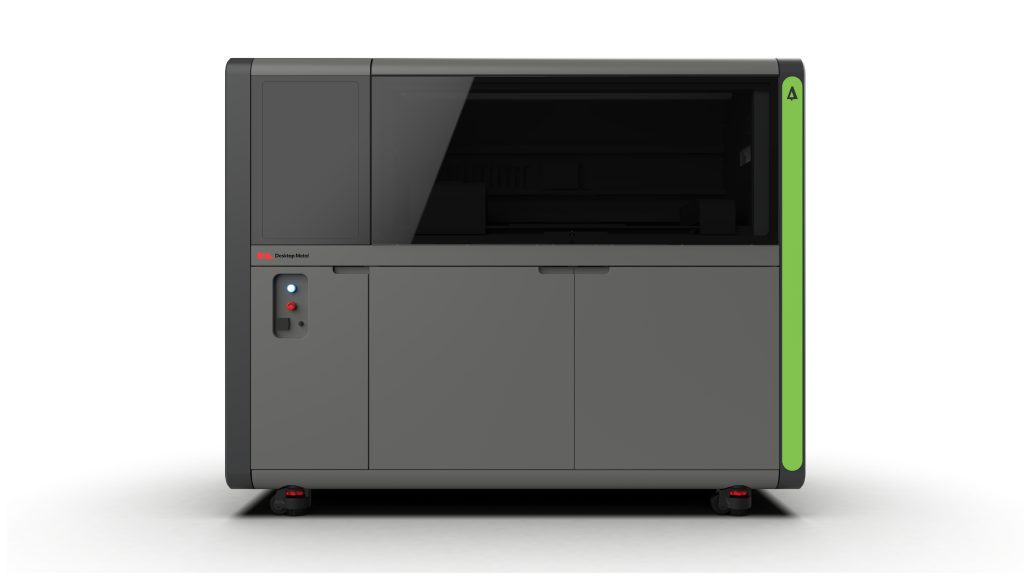

While based on Desktop Metal’s Shop System, its first commercially-available Forust machine has been modified to safely process the unfinished sawdust byproduct of the wood milling industry. Like its predecessor, the Forust Edition works by using an industrial printhead to selectively deposit binder onto a powder bed, only it does so much more quickly, at speeds of up to 1,600 cc/hr rather than 800 cc/hr.

Interestingly, when used with Desktop Metal’s Fabricate MFG build preparation software, the machine allows users to either print with no grain pattern, or choose from five presets. In practice, this means adopters will now be able to manufacture custom home decor pieces with realistic patterning, which accurately replicates that of natural woods like ash and mahogany.

After infiltration, Forust parts can also be sanded, stained, polished, dyed, coated, and refinished just like traditional wood products, and once finished, these are said to have a similar level of strength, meaning that they can be screwed or nailed.

At launch, the Forust Edition ships with Forust Wood Powder, a blend of raw and unfinished sawdust, but Desktop Metal is also developing guidelines to allow users to print their own materials. In future, the firm expects its machine to be popular among service bureaus, architects and designers, as it enables the production of high-quality custom wood products that combine flair with functionality.

Technical specifications and pricing

Below are the technical specifications for the Desktop Metal Forust Shop System. Desktop Metal has announced that the 3D printer is now “available to purchase internationally.” Those interested in buying the machine can request a quote from the company directly, or take a closer look when it debuts at Formnext from November 15-18, 2022.

| Technology | Binder Jetting |

| Build Box | 350 x 220 x 200 mm |

| Print Speed | Up to 1,600 cc/hr |

| Materials | Forust Wood Powder |

| Software | Fabricate MFG |

| Anicillaries | Forust Powder Station |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a render of Desktop Metal’s Shop System Forust Edition. Image via Business Wire, Desktop Metal.