Swedish software developer Hexagon and aerospace firm Raytheon Technologies have developed a program that allows metal 3D printer users to predict and prevent part defects before they happen.

Developed using the firms’ joint software expertise, the program is said to allow designers to evaluate the outcome of an upcoming print, without having to go through painstaking trial and error. Designed to compliment Hexagon’s Simufact Additive platform, the software tool is said to be launching with a similar UI, so that users can access greater functionality but don’t have to relearn interfaces.

“We’ve partnered with Raytheon Technologies to deliver an intuitive and accessible tool that will help engineers quickly predict and mitigate risks,” said Jeff Robertson, Director of Global Business Development at Hexagon. “The ability to evaluate full laser powder bed fusion (LPBF) parts on the meso-scale will reduce the effort to achieve part certification and thereby support industrialization.”

Raytheon’s 3D printing excursions

Based in Virginia, Raytheon is an aerospace and defense multinational. As such, the firm’s R&D efforts span multiple industries and technologies, but it has maintained a longstanding interest in 3D printing, particularly on the aerospace side of its business. In July 2020, America Makes named Raytheon as the winner of one of its Project Calls, along with its $841,000 funding prize.

The firm’s project submission, which included input from its Intelligence and Space, Missiles and Defense, and Research Center divisions, proposed the development of a revised LPBF software workflow. Using this, Raytheon said it’d be possible for adopters to easily create topologically optimized ‘exotic designs’ with conventional additive materials, like optimized 3D printed optical mounts for the US Air Force.

Engine manufacturer and Raytheon subsidiary Pratt & Whitney is also a long-term adopter of the technology. At the International Paris Air Show in 2019, GKN Aerospace revealed that it had expanded its partnership with the company into the 3D printing of GTF engine parts, including a Fabricated Fan Case Mount Ring and Fan Spacer.

Complimenting Simufact Additive

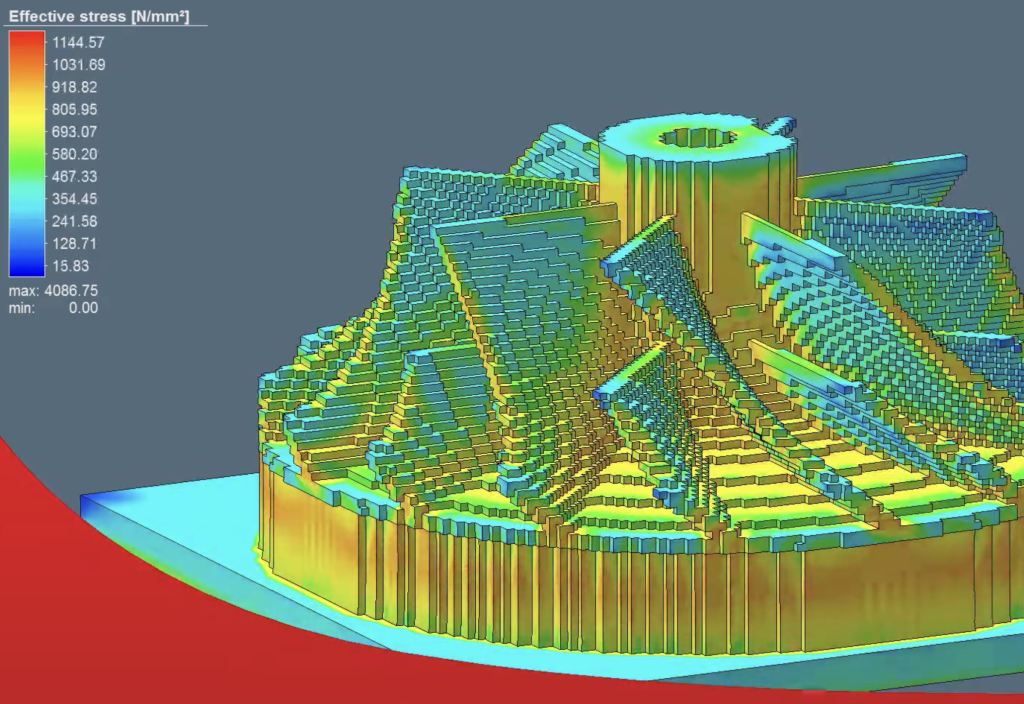

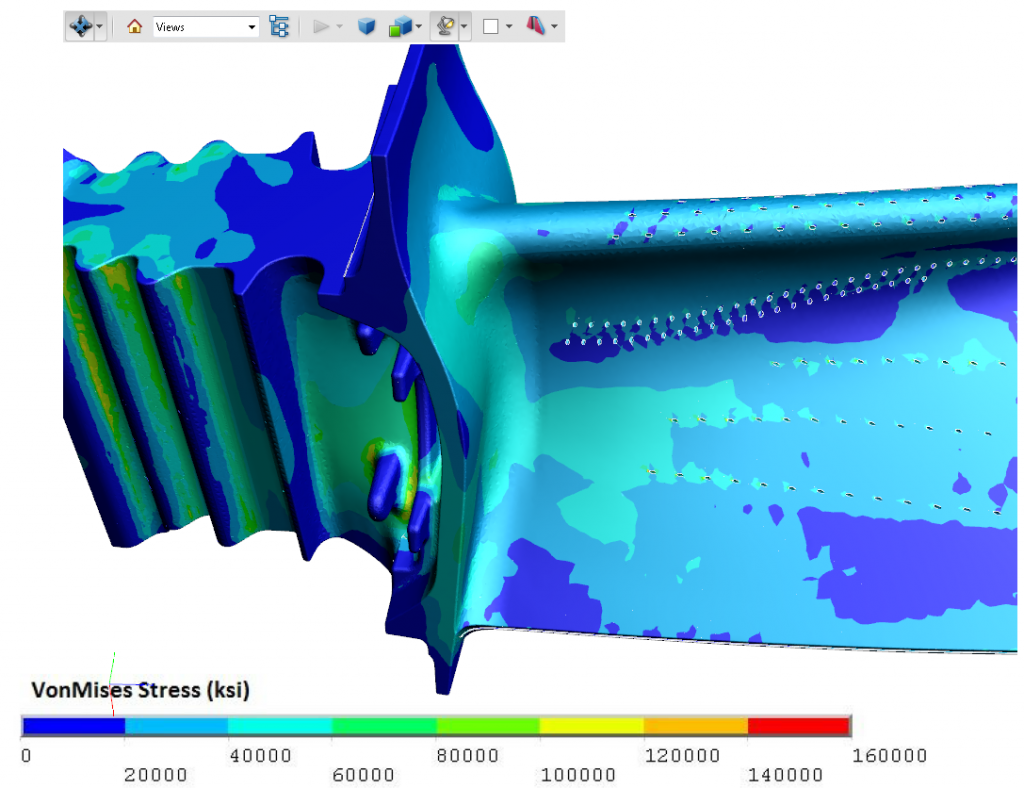

Hexagon’s existing Simufact Additive program is designed to enable metal 3D printer users to slash time spent on testing, by simulating builds before they’re printed. Compatible with LPBF, Direct Energy Deposition (DED) and binder jetting technologies, the platform takes a multi-scale approach to tackling issues, which ranges from mechanical checking to full thermal-mechanical transient analysis.

The platform itself is based around numerical simulation specialist MSC Software’s MARC solver, a technology that covers a wide range of physical effects that’s been adapted for 3D printing. In Simufact Additive, the software tool allows users to minimize residual stresses, compensate for distortions, identify potential part failures, assess post-processing impact, optimize build plate nesting and more.

Essentially, the program does so by enabling adopters to simulate prints before comparing results to a build’s target geometry, in a way that makes defects clear, and then highlighting fixes through analyses. According to Hexagon, Simufact Additive ultimately reduces the learning processes of manufacturers, while ensuring they optimize employee productivity and minimize their products’ times-to-market.

In its latest software innovation, Hexagon’s Manufacturing Intelligence division has worked with Raytheon Technologies’ Pratt and Whitney business, to develop a brand new simulation tool. As well as being complementary to Simufact Additive, it has been revealed that the technology will enable designers to evaluate print outcomes based on a combination of materials, geometries and print processes.

It’s also said the similarity of the software’s UI will allow for its easy integration into existing manufacturing processes without the need for extensive training, something David Furrer, Pratt & Whitney’s senior fellow for materials and processes, adds will “help manufacturers with all levels of experience make better products with greater efficiency.”

Though there’s no doubt Simufact Additive has proven popular, as its clientbase includes the likes of Audi, Mercedes and Jaguar, it’s far from the only software in this space. ANSYS Additive Print, for instance, allows users to assess how materials stress or distort during a build, and takes corrective steps to get the parts right first time.

Similarly, Riven’s Warp Adapted Model software allows users to capture and use full-part 3D data from an initial design to identify and correct errors in minutes. Designed to work with Authentise AMES, the FFF, SLA, MJF and binder jetting-compatible technology unlocks full contextual data capturing, as a means of picking out divergences from part models.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Hexagon’s Simufact Additive platform being used to analyze a part. Image via Hexagon.