SelectAm’s new software for part identification now supports a broader range of input files and is available for a free trial.

SelectAM is a Finnish AM software company with tools to identify parts that are suitable for 3D printing in a company’s inventory. This allows businesses to understand if there is a “viable business case” for 3D printing a component. Now SelectAM has launched a free tier of its software where potential customers can test the software free for one month.

Finding appropriate and financially feasible use cases has been a significant barrier and demotivator for businesses and engineers interested in the field of additive manufacturing at scale. The company wants to assist consumers in focusing on the appropriate components and applications that are suitable for manufacturing with additive methods. “Based on the data from our research and customer projects, a small percentage of the parts that run through our process appear as a viable business case as they are today,” said Dr. Niklas Kretzschmar, Co-founder & CEO of SelectAM Oy. “In addition, since we also expand our assessment to supply chain critical parts and future business cases after redesigning the part or assembly for AM, a larger business case percentage is achievable.”

SelectAM software for accelerating AM adoption

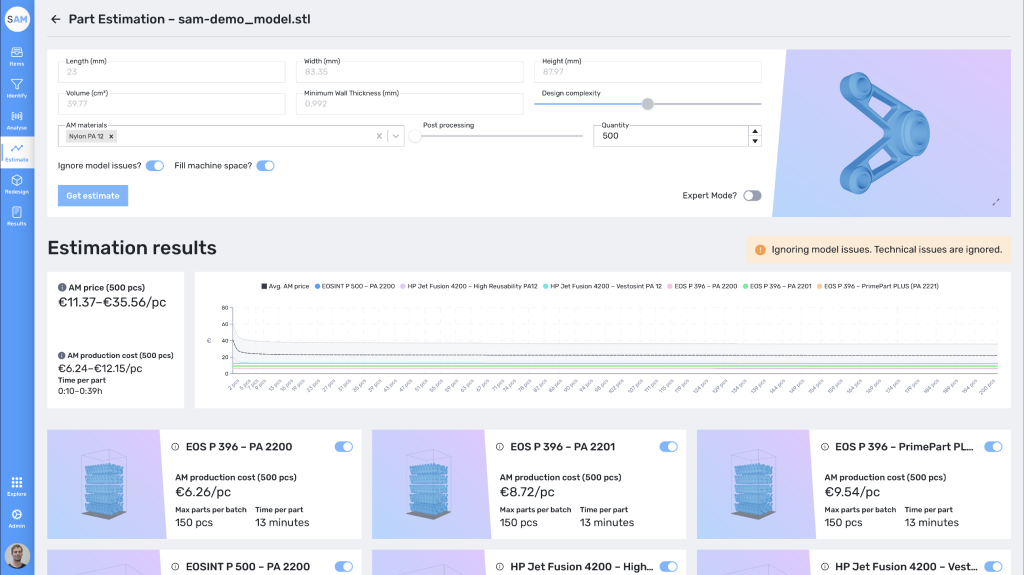

SelectAM’s software includes an embedded rapid slicer suitable for all the relevant additive manufacturing processes. The software also enables automated material mapping between traditional and AM materials.

Machine utilization can also be optimized by the usage of varied nesting strategies. These strategies can help reduce raw material waste. Analyzing each assembly and single part and checking the redesign potential of the product is enabled by the software. Users can establish their own machine and material equipment profile. The software examines the part’s surface roughness and tolerances.

Digital Inventory scanning

Digital inventory can describe a company’s method of tracking real-time inventory activity. It entails inventory monitoring systems to track data and gather information as finished goods move through the supply chain, improving visibility. Digital inventory can also refer to keeping designs of physical products in a digital format, ready to be manufactured on demand, when and where needed.

Digital Inventory is a hot topic, especially with changes in EU legislation. 3D printing has the potential to help many enterprises comply with new Right to Repair EU laws. According to the new EU Ecodesign and Energy Labelling legislation, consumers will have the legal right to fix the goods they purchase starting in the summer of 2021. This means that manufacturers must legally keep spare parts for their products available to customers for up to 10 years. Leading 3D printer company EOS believes the new “Right to Repair” program may have a beneficial overall impact because prolonging a product’s lifespan is both economically advantageous and helps to promote more considerate resource use. According to Additive Manufacturing Consultant at EOS, Nicolas Dill, the same philosophy may be applied to machinery and manufacturing equipment, where end users gain from prolonged machine lifetimes.

Elsewhere, Philadelphia-based Authentise, a leader in data-driven manufacturing and workflow solutions, launched the Digital Design Warehouse (DDW) to simplify the sharing of digital designs. DDW will help businesses create additive manufacturing projects that are more cohesive by bringing data from diverse silos into full view across all teams.

3D printing database to identify potential time and cost savings

By discarding conventional tooling techniques and shortening the lead times for prototypes and final products, mass production with 3D printing can reduce time to market. Additionally, 3D printing makes it possible to dramatically cut jig and fixture costs through part count reductions, easier fabrication of intricate geometries, and even lightweighting, which lowers product weight and enhances worker ergonomics.

For instance, the development of a 3D printing database has received support from EIT Digital, a digital innovation, education, and community accelerator of the European Institute of Innovation & Technology (EIT). The directory, which was created to assist manufacturers in identifying potential time and cost advantages, hopes to persuade more companies to transition to 3D printing from traditional techniques.

Aalto University in Finland previously created a database, made available as a plugin for DeskArtes, a Finnish industrial partner that makes 3D data expert software. Siemens, a top manufacturer, and producer of 3D software developed knowledge graphs for the system to ensure rational connections between all gathered data.

Nominations for the 3D Printing Industry Awards 2022 have now commenced. Who do you think should make it to the shortlists for this year’s show? Nominate now, the form closes at the end of the month.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.