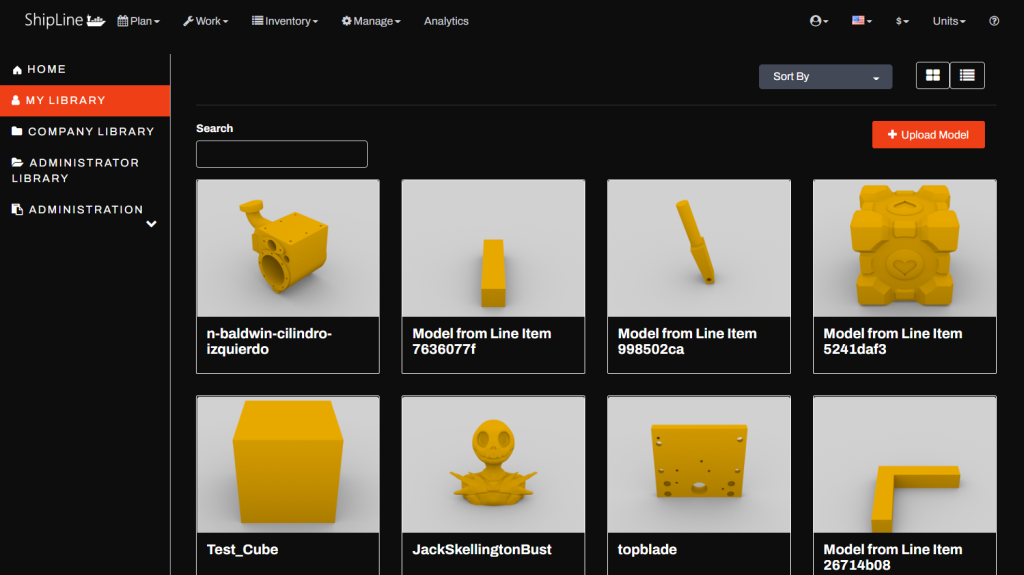

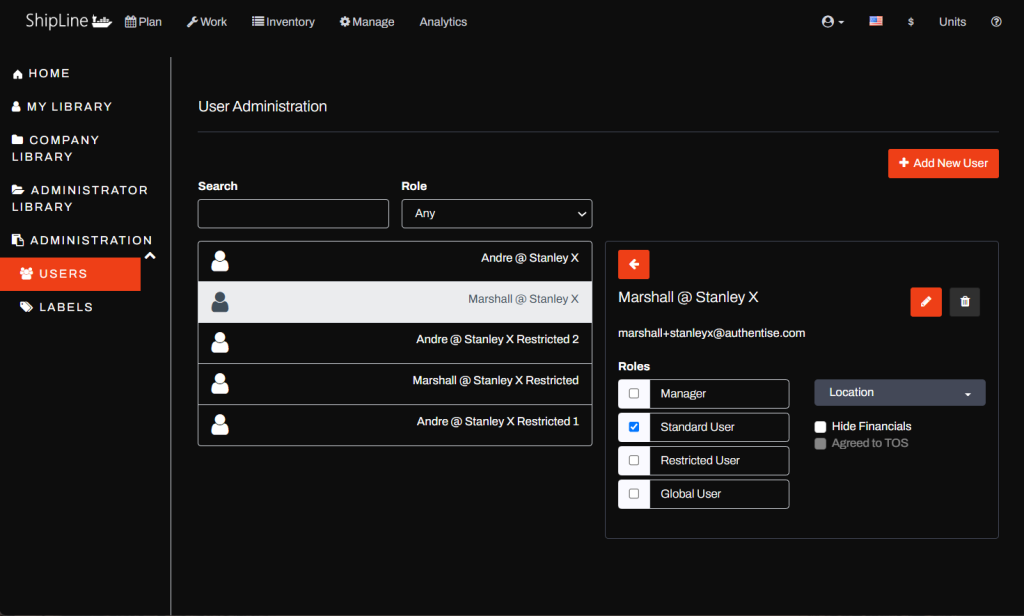

The Digital Design Warehouse provides a space for users to view or access designs, edit, and collaborate.

Authentise is a Philadelphia-based pioneer in data-driven manufacturing and workflow solutions. A significant new product has been developed by the firm to streamline the sharing of digital designs, the Digital Design Warehouse (DDW). By bringing data from various silos into full view across all teams, DDW will assist enterprises in developing additive manufacturing projects that are more cohesive. The platform enables everyone to upload any 2D and 3D file type with fully programmable additional characteristics to create their own personal library. These designs can be further examined with the use of third-party plugins like Castor, which evaluates the project’s viability for additive manufacturing, and Zverse, which facilitates the conversion from 2D to 3D.

“The market for additively manufactured spare parts is rapidly evolving,” said Omer Blaier, CEO of Castor. “We’ve helped many companies assess the additive opportunities in their portfolio and acquire large databases of designs ready for action. What’s missing is a tool to help them develop those projects and then securely share those designs with production facilities. We’re delighted to see Authentise moving to fill the void and excited to be part of the project.”

“We are thrilled to launch the Digital Design Warehouse,” said Andre Wegner, CEO of Authentise. “The launch today shows that the distributed manufacturing dream that Authentise was founded on 10 years ago is not dead. We can only accomplish this by working together, so we’re excited to launch two new integrations to Authentise’s open platform.”

Dana Air Flight 0992 incident

“The time is finally right to dig into the spare parts opportunity,” said the CEO & Founder of Authentise, “We’ve been waiting for that space to mature ever since the Dana Air Crash in Nigeria (2012), which killed 159 and was caused by planes staying in the air despite missing spare parts.”

Dana Air Flight 0992 was a scheduled Nigerian domestic passenger flight from Abuja to Lagos, Nigeria. During its approach to Lagos on June 3, 2012, the McDonnell Douglas MD-83 aircraft operating the route experienced a dual-engine failure. All 153 people on board as well as six individuals on the ground were killed when it crashed into buildings instead of arriving at its intended location.

According to the Nigerian Accident Investigation Bureau (AIB), both aircraft’s engines lost power as they approached Lagos. The incorrect assembly had severed the engines’ fuel line.

Digital spare parts warehouse and cracking the supply chain challenge

Traditional manufacturing processes usually need a volume of spare parts, tooling, consumables, and more for ensuring maximum uptime. The costs associated with holding these parts on-site can drastically decrease the efficiency of the manufacturing process. With digital inventory, some spare parts, particularly lower-demand parts, like obsolete components, can be redesigned for 3D printing and stored in a virtual parts catalog, freeing up space in a warehouse.

For example, Deutsche Bahn (DB), a German railroad business, and 3YOURMIND, a 3D printing software developer based in Berlin, have worked together to tackle supply chain and logistic challenges. DB intends to create a “digital spare parts warehouse” utilizing the 3YOURMIND digital process, sourcing 3D printing ideas from its employees.

Elsewhere, the US Department of Defense (DoD) has unveiled its first complete additive manufacturing strategy. “Additive manufacturing offers DoD unprecedented supply chain agility while enabling our developers to sustain technological dominance for our Warfighters,” said Robert Gold, Director of the Technology and Manufacturing Industrial Base (TMIB) in the Strategic Technology Protection and Exploitation Office (STP&E), and overseer of OSD ManTech. In collaboration with the US military services and other defense agencies, the Office of the Secretary of Defense Manufacturing Technology (OSD ManTech) Program Office created the strategy, stating five strategic goals to increase the adoption of 3D printing throughout the defense industry.

Nominations for the 3D Printing Industry Awards 2022 have now commenced. Who do you think should make it to the shortlists for this year’s show? Nominate now, the form closes at the end of the month.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.