The CATIA software division of Dassault Systèmes (DS) wanted to demonstrate its ability to prototype a car with CAD and 3D printing, so, naturally, they invented a car. Though not a real, functional automobile, Project Bleu, led by Xavier Melkonian, was CATIA/DS’s way of showing off the sorts of prototypes they could create, using their own software and an Objet260 Connex Multi-material 3D Printer from Stratasys.

Laurent Igarza explains that Bleu, with copyrights belonging to Dassault Systèmes, could be taken to industry shows, telling Stratasys, “The primary goal of Project Bleu was to create our own in-house show car from scratch, demonstrating our latest modeling technologies from the CATIA design suite.” Designed and built over the course of 2013, Bleu was brought about by a team of one creative designer, two concept modelers, two visualization experts, two class A surfaces modelers, and one mechanical modeler. And, as the concept car was designed, it was 3D printed at various stages to push the process along, with Igarza saying, “The very fine printer resolution (33 microns using 2 materials at the same time) allowed us to cross check & definitively validate the design on the 3D printed models compared with the previous realistic pictures we had just produced with [the] CATIA Live Rendering application.”

First, the team printed 5 cm models of the car, to analyze for basic design flaws before proceeding. Next, the cars were blown up to 10 cm in size, to inspect the volumes and proportions of their various design elements. Igarza elucidates, “We found out that small scale 3D printing was so complementary to any ‘scale 1’ reviews to validate design or reveal mistakes that we actually followed this process all along the ideation phase.”

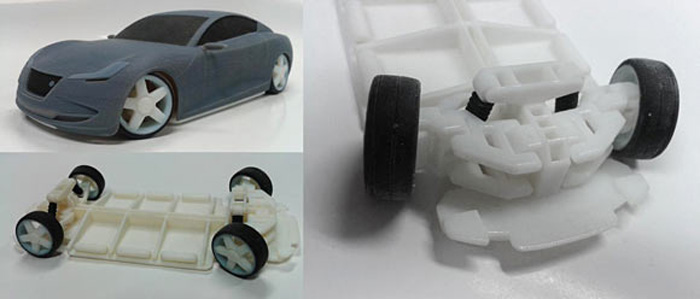

The team then printed a speedform model. Stripped of wheels, mirrors and the interior of the car, the model was placed in a wind tunnel for aerodynamic testing. The next step was to enlarge Bleu as much as possible, complete with mirrors and bumpers, filling the entire 26 cm of the Objet260 build tray.

Satisfied with the result, the team was ready to modify the chassis of the car so that the wheels could rotate, making Bleu into something of a functional toy. At this point, the full range of the Connex Multi-material system could be taken advantage of. Using TangoBlackPlus rubber-like material for the wheels, rigid opaque VeroWhitePlus for the undercarriage, and VeroClear transparent material for the windows, Bleu became a stunning physical reality. Igarza points out, “The rubber-like feel of the black rubber-like material (TangoBlackPlus) was a great simulator for real tires.” The project was finally completed and both the design process and the physical prototype was ready to be displayed. Next, the team plans to upload the technical steps and .stl files involved in the project and make them available to the community.

In the video below, you’ll see the CAD/CAM design process. The uninterrupted screengrabs of the designer at work make me wonder if he was able to take any breaks from making Bleu to go on YouTube or anything.

Source: Stratasys