Q: What’s like a 3D printer, but also like a microscope? A: The C.E.M Crown Extruder.

Cem Schnitzler wants to know why a 3D printer can’t function more like a microscope, with multiple nozzles for multiple printing styles, all fixed to the print head.

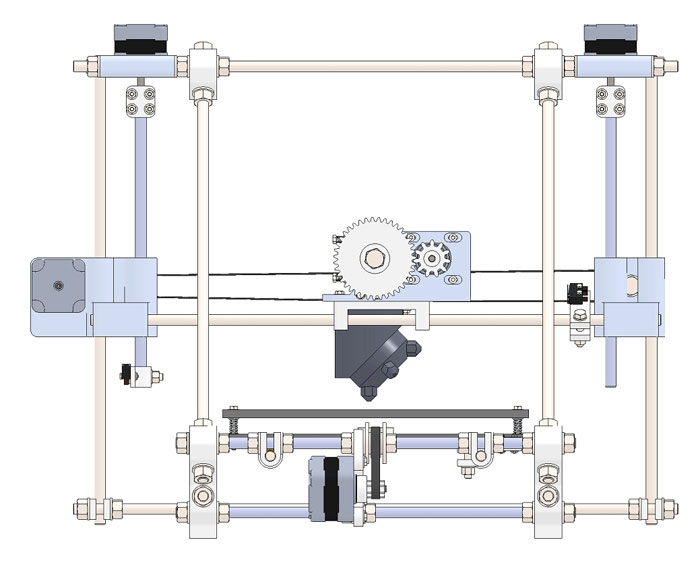

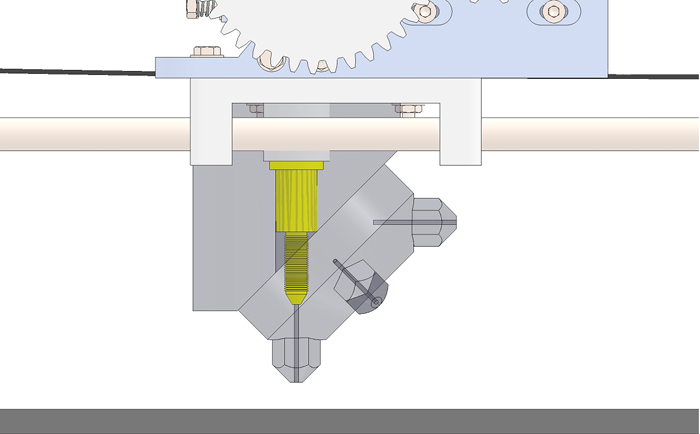

If you look at the site for the 3D , you may recognize the aesthetic and the creator’s name from the Make Fresh Water project, previously covered on 3DPI. This time around, Cem ponders, “When you use a microscope and the resolution is not enough you turn the head and get a better resolution. So, why we don’t develop an extruder [with] this principle?” Though he hasn’t yet created a proof of concept, Cem has whipped up some detailed drawings of how it might work.

Like a microscope, different diameter printer nozzles are fixed onto a single, rotating component. When you need to print with a 4mm nozzle for a specific type of filament, you can spin the turret to the proper nozzle and begin printing. Cem envisions a stepper motor attached to the turret so that the printer can automatically, given the right code, and switch heads during a print job. That way, the printer can extrude from a larger diameter hole for quick and dirty infills and back to a smaller nozzle for fine details. This set-up has already been executed in one form by the Robox 3D printer , which has a dual print head for just such a reason.

Such an idea, coupled with possible simple improvements to how filament is fed to the printhead for a greater range of materials, could greatly improve the finesse with which FFF 3D printers fabricate objects. Thanks to the RepRap revolution, we’ve got the basics of a very useable 3D printer. Now, we’ll see people, like those in the DIY community, fine tune it. I hope that they catch wind of this article or that Cem submits his ideas to the RepRap forums in the future!

Source: C.E.M. Crown Extruder