RepRapPro founder and instigator of the RepRap movement, Adrian Bowyer, has done to multimaterial 3D printing what RepRap does best: keep it neat and simple. Fellas and fellers out there will tell you that the only way to do multimaterial FDM/FFF 3D printing is with multiple heads (barring all sorts of experimentation and, possibly, unsubstantiated hype). Bowyer, with the help of a RepRapPro customer, has come up with a method for multi-material 3D printing with a single extruder.

Bowyer explains that this method does away with some problems associated with multi-headed machines. For instance, Gcodes no longer have to account for more than one Z-axis height, associated with each extruder. Dripping filament from a recently used print head is no longer a problem either. And, in order to shift from one colour to the next, the machine can purge the last colour while printing the interior of an object before going onto the next colour.

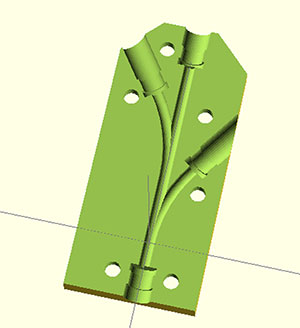

Of course, after the experiments prove successful, there are ways that this technique can be optimized. Fairhurst, for example, has created a similar apparatus that uses three different drive motors to feed each line of filament. Bowyer seems quite confident about the railway method, explaining that it might be possible to increase the number of filaments leading to the extruder, “The nice thing about all this, of course, is that the merged guides don’t have to lie in a plane. You could print rings of them and have lots of feeds all going into the same head. And when I say lots, I do mean 20…”

If you’d like to try to tackle the task of feeding 20 lines of filament to your print head, you can find Bowyer’s source file here. Let us know if you succeed because, when you do, there’s a chance that every desktop FFF manufacturer will want at it.

Source: RepRapPro