Children’s Healthcare of Atlanta (CHoA) and the Georgia Institute of Technology (Georgia Tech) have successfully used 3D printed tracheal splints in the pediatric surgery of a 7-month old patient with a life-threatening airway obstruction.

The surgeons of CHoA used three custom-made splints, which were made by biomedical engineers of Georgia Tech. Donna Hyland, President and CEO, CHoA, said, “This is a great example of how aligning Children’s clinical expertise with the missions of our research collaborators can improve patient outcomes.”

“Research that can be translated into more effective care at the bedside is why our collaboration with Georgia Tech is so important for the future of pediatric care in Georgia.”

3D printing for complex surgery

The patient was suffering with congenital heart disease and an uncommon medical condition called tracheo-bronchomalacia, a life-threatening condition. During the course of a six-month hospitalisation at CHoA Pediatric Intensive Care Unit, the patient endured repeated episodes of airway collapse that were impossible correct by regular surgery methods.

The Pediatric Technology Center is a joint initiative supported by Georgia Tech and CHoA. Scott Hollister, Ph.D., director of the Center for 3D Medical Fabrication at Georgia Tech, developed this process for creating the tracheal splint using additive manufacturing technology at C.S. Mott Children’s Hospital.

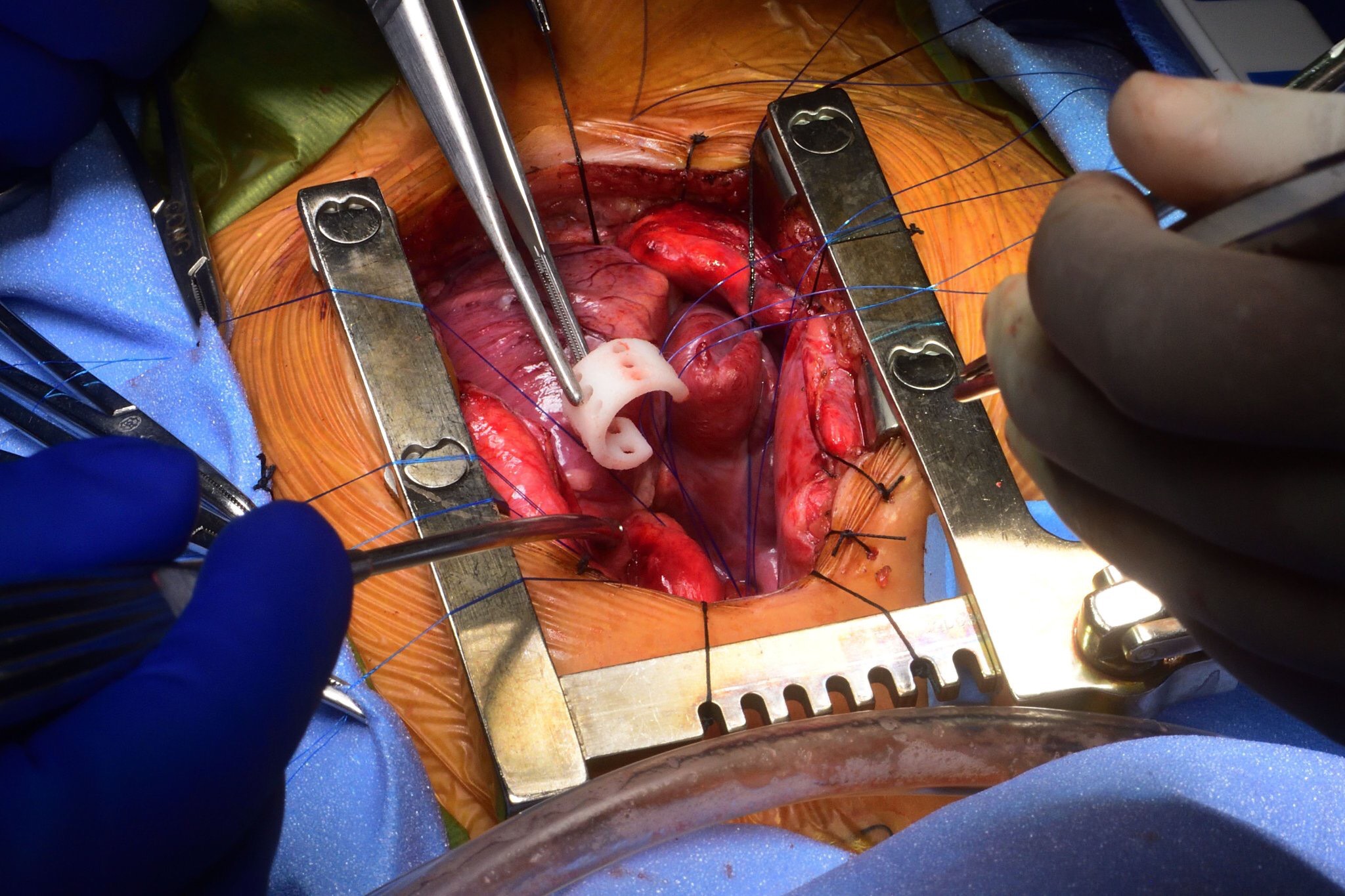

The procedure begins by obtaining the CT scan of the patient’s airway. The splints are then accurately designed and created to find a perfect fit for the surgical team to place during the surgery. Afterwards, the 3D model of the splint is scanned using a laser, and a pattern is developed.

The arm within the printer spreads the polycaprolactone (PCL) powder into the developing area, followed by the laser tracing the pattern and fusing the particles closely. Over a period of 3-4 years, this material gets absorbed into the patient’s body, achieving the expansion of the trachea and bronchus.

The 3D printed tracheal splint is a new device still in development. Its medical safety and efficiency is not yet resolved. When the CHoA’s team proposed an experimental insertion of the device, they required emergency clearance from the FDA to step ahead with the surgery subjected to expanded access guidelines. CHoA’s procedure was the 15th time a pediatric patient has benefited from such a 3D printed tracheal splint. Hollister stated:

“The possibility of using 3D printing technology to save the life of a child is our motivation in the lab every day. We’re determined to develop innovative solutions that meet the needs of Georgia’s most complex pediatric patients.”

Groundbreaking results using 3D printing

The Global Center for Medical Innovation (GCMI) collaborated with Hollister and his team of biomedical engineers to create various versions of the splints, of different sizes to find the perfect fit. GCMI has also agreed to support the continuing development and commercialisation of the technology.

On August 17, 2018, CHoA’s interdisciplinary team of surgeons successfully placed three 3D printed splints around the patient’s trachea in a complicated 10-hour surgery.

The CHoA’s tracheal splint team included Steve Goudy, M.D., and April Landry, M.D., (ENT), pediatric otolaryngologists; Subhadra Shashidharan, M.D., pediatric cardiothoracic surgeon; and Kevin Maher, M.D., pediatric cardiologist.

“It’s the close relationships we have with our research collaborators that make this kind of groundbreaking procedure possible,” said Dr. Goudy.

In May 2015, a 3D printed trachea was implanted in a child for the first time. The use of 3D printed implants gained a traction around the world by 2016. In Argentina, after the surgery, a woman was able to speak, eat and do normal activities which was not possible otherwise. Following the success of the operation, the surgeons performed similar procedure on other patients as well. In 2017, a biomedical researcher, Dr. Achala de Mel and her team used FDM 3D printing to fabricate a range of plastic tubular structures which could be used to culture the building blocks of body tissues.

For medical updates and more subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Sign up to 3D Printing Jobs here and kickstart a new career.

Featured image shows 3D printed tracheal splints. Photo via Georgia Tech.