Researchers from Georgia Institute of Technology have used 3D printers to create tensegrity objects which can change shape. The 3D printed structures are capable of dramatic expansion and have the potential to be used in biomedicine and perhaps in space where weight and size really matters.

What is tensegrity?

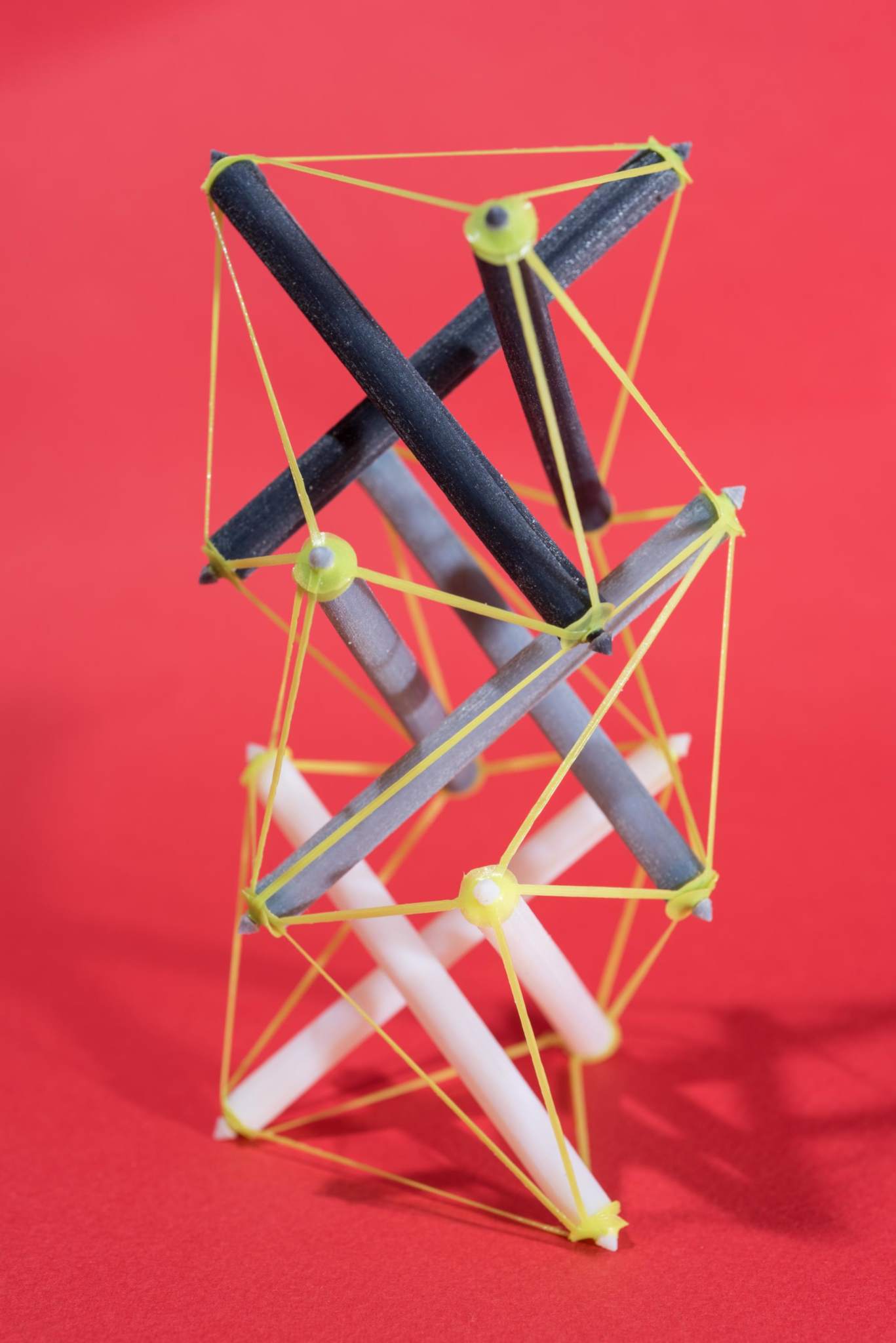

Otherwise known as tensional integrity, tensegrity is a structural principle that is based on components held in compression through continuous tension. This means the structure’s integrity is contained in the balance of tension members. In this case, the researchers have applied the principle of tensegrity with shape memory polymers that can merge into certain shapes when applied with heat.

The method of 3D printing shape memory polymers is often referred to as 4D printing for the ability of an object to change shape over time. A number of projects have developed such objects, particularly from Singapore, with researchers developing 4D printed objects in collaboration with Georgia Tech. Similarly, another group of Singapore researchers explored the durability of 4D printed structures. However, we have not seen 4D printing combined with principles of tensegrity before.

Gif shows one of the smaller structures unfolding as the water raises in temperature. Images via Georgia Tech.

Heating up

The struts in the research were 3D printed with shape memory polymers to enable unfolding when submerged in warm water. The cables that hold the struts were also 3D printed using Filaflex material.

Importantly, as the temperature increases different struts unfold so that the structure does not become entangled. The research project was able to control the temperature at which the struts would unfold so that it was sequential and not all at the same time.

Applying 3D printed tensegrity

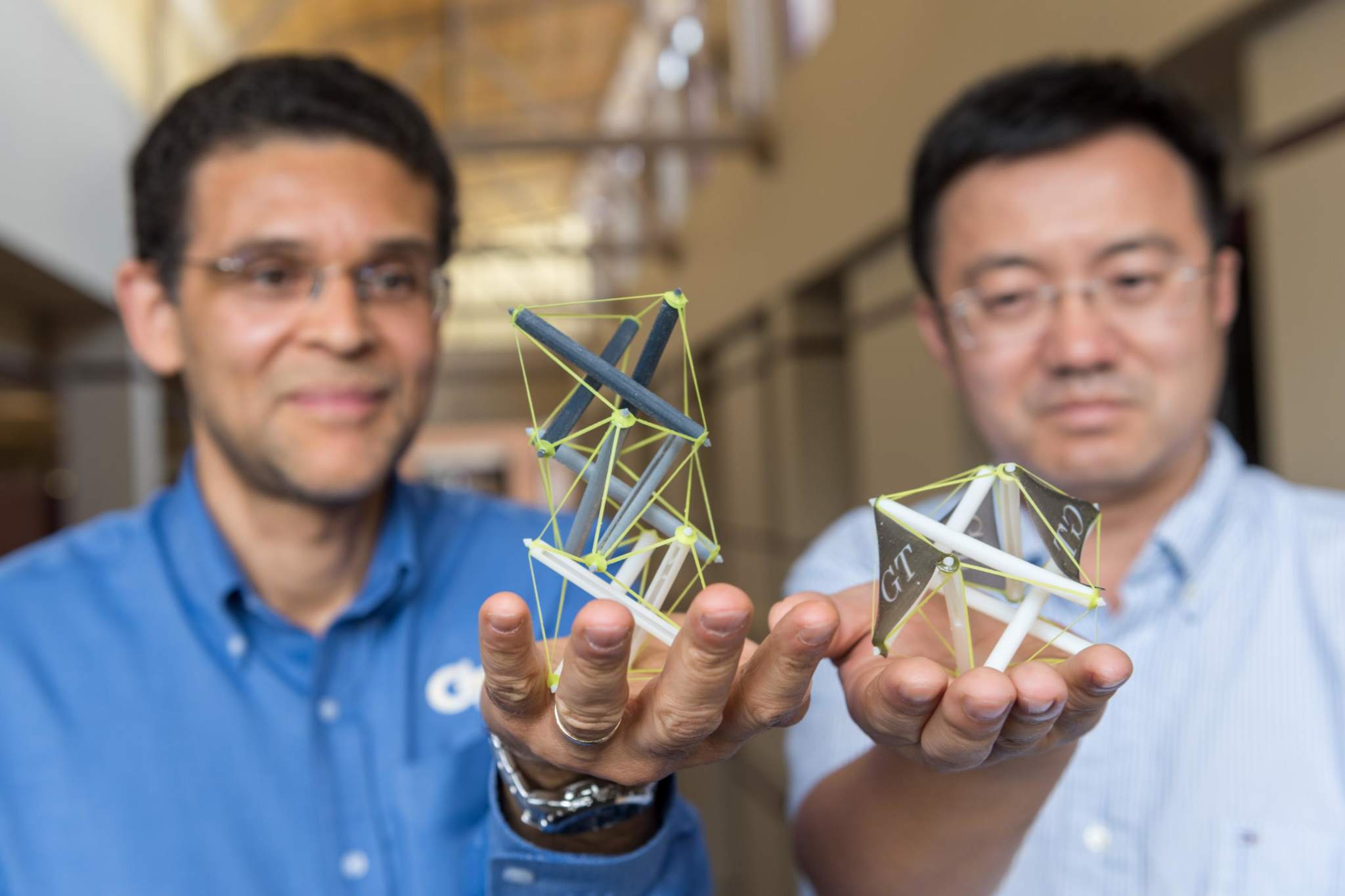

The researchers believe the method has potential to create lightweight structures for space and perhaps even shape-changing soft robots. Working on the project was Glaucio Paulino, a professor at Georgia Tech’s School of Civil and Environmental Engineering and he explains the benefits of tensegrity objects,

Tensegrity structures are extremely lightweight while also being very strong. That’s the reason there’s a heavy amount of interest right now in researching the use of tensegrity structures for outer space exploration. The goal is to find a way to deploy a large object that initially takes up little space.

Tensegrity in space

Fellow researcher Jerry Qi, professor in the George W. Woodruff School of Mechanical Engineering at Georgia Tech, also explains the potential for space,

We believe that you could build something like an antenna that initially is compressed and takes up little space, but once it’s heated, say just from the heat of the sun, would fully expand,

With International Space Station now equipped with its own 3D printer, the structures would not even need to be launched from earth.

The research paper written written by Ke Liu, Jiangtao Wu, Glaucio H. Paulino, and H. Jerry Qi, – titled “Programmable Deployment of Tensegrity Structures by Stimulus-Responsive Polymers,” has been published in Scientific Reports.

For the latest news on 3D printing research, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows one of the tensegrity designs Photo via Rob Felt/Georgia Tech.