As a corn-based and biodegradable plastic, PLA, the material used in almost every desktop 3D printer, has been researched for its potential industrial applications. The material is particularly desirable in place of other plastics, like ABS, as they are typically petroleum-based and harmful to the environment.

With research dating back to 2008, Professor Alan Lau and his research teams have been looking into ways to make PLA suited to biomedical applications. Now at Swinburne University of Technology, Professor Lau has revealed that the investigations are ready for a collaborator, to test the material in living organisms. After this stage, the devised PLA composite could reach clinical trials, which can lead to its use as an alternative medical implant for humans.

An alternative to toxic plastic and metal

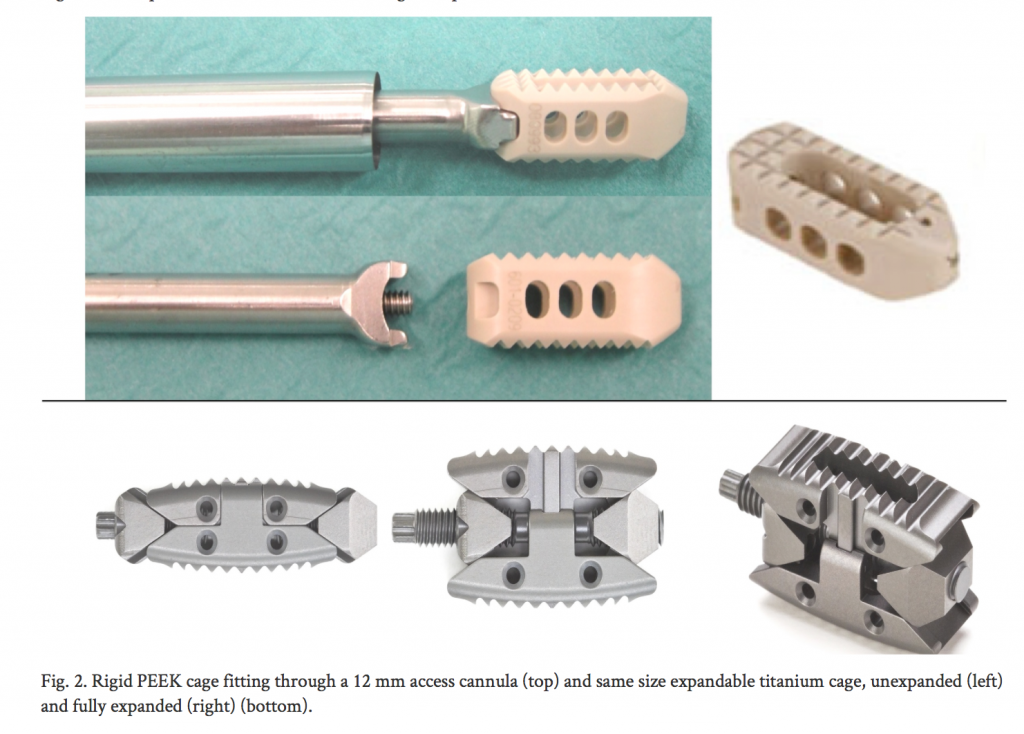

Medical implants, used to pin together broken bones and create support in the body, are typically made from metal, i.e. stainless steel or titanium, or a high strength plastic like PEEK. Though these implants have the structural integrity required in bone repair, their main disadvantage is that the implant has to be removed at a later stage in the patient’s life. Removal of the constructs can leave bones brittle, and also causes more risk to the patient through a subsequent operation.

PLA by comparison does not have the structural integrity of materials like steel and PEEK. It’s gradual absorbance into the body however, makes the material a more attractive alternative. And so Professor Lau’s research has been looking at ways to improve the strength of PLA.

One of the strongest fibers in nature

Silk is one of the strongest fibers in the natural world. Made of a triangular cross-section of connecting fibroin proteins, the material forms hydrogen bonds within its structure, which is the secret to its strength.

In Professor Lau’s research, silk fibers are added to PLA as a structural reinforcement.

In findings presented at the 9th International Symposium on Processing and Fabrication of Advanced Materials, adding silk proved to increase the Young’s modulus of the material. To start, the base PLA presented a GPa of 3.21. When the silk was added, this increased by 27% to 4.08 GPa, putting the stiffness more inline with the properties of nylon or MDF, but still retaining biodegradability.

Strengthening bones with 3D printed silk

In current applications at Swinburne University of Technology, Professor Lau’s team are working on creating surgical pins and cages out of the silk PLA composite. Speaking to Research Impact magazine, Lau also envisions the fabrication of custom made implants in the material using 3D printing and scanning techniques. He says, “At this stage we have a great accomplishment, but there’s still a long way to go.”

Research at the University of Florida, and in South Korea, has also been investigating the application of silk in 3D printable materials. By contrast, at CWRU graphene nanotubes have been added to PLA in another attempt to make the material stronger for medical application.

For all the latest 3D printing news and research subscribe to our free newsletter. If you want to join the conversation then follow the most popular social media accounts in the 3D printing industry.

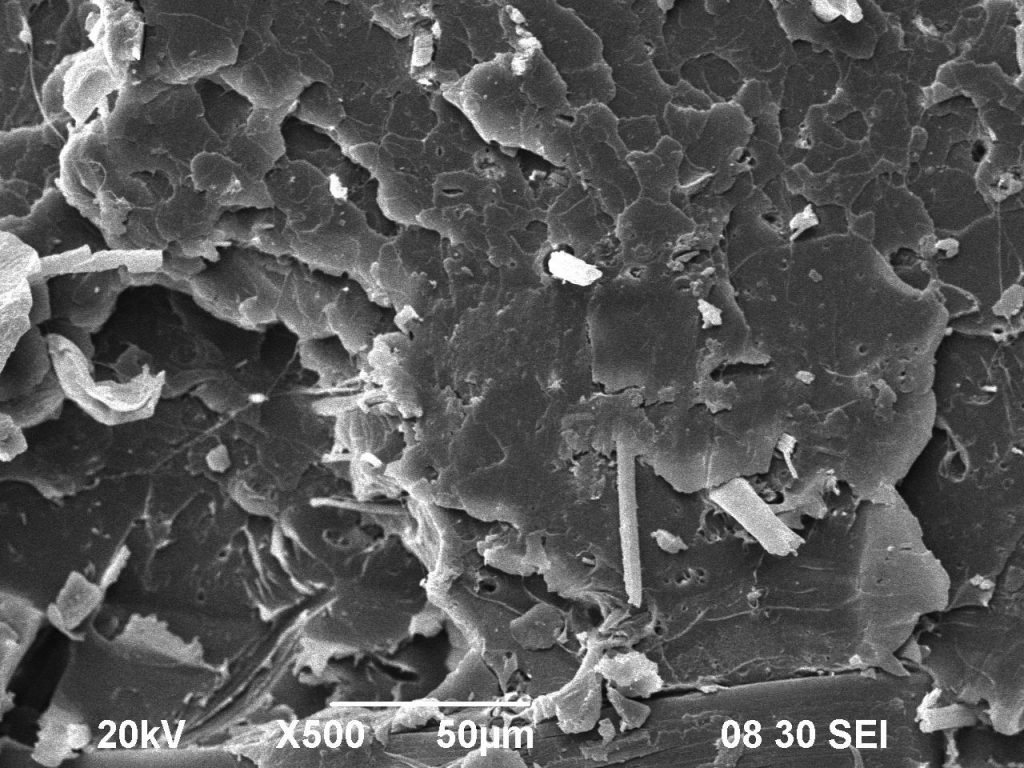

Featured image: SEM image of the surface of PLA plastic. Image via Ho, Lau, Wang & Bhattacharyya