4D printing is a method created to push the boundaries of what is possible with a 3D printer.

The term was first coined in a TED Talk by Skylar Tibbits, an associate professor of architecture at the Massachusetts Institute of Technology (MIT).

Put simply, the method uses 3D printing to make a flat map of an object. When this map is exposed to environmental changes, i.e. heat or moisture, it transforms itself into a new, pre-determined 3D shape.

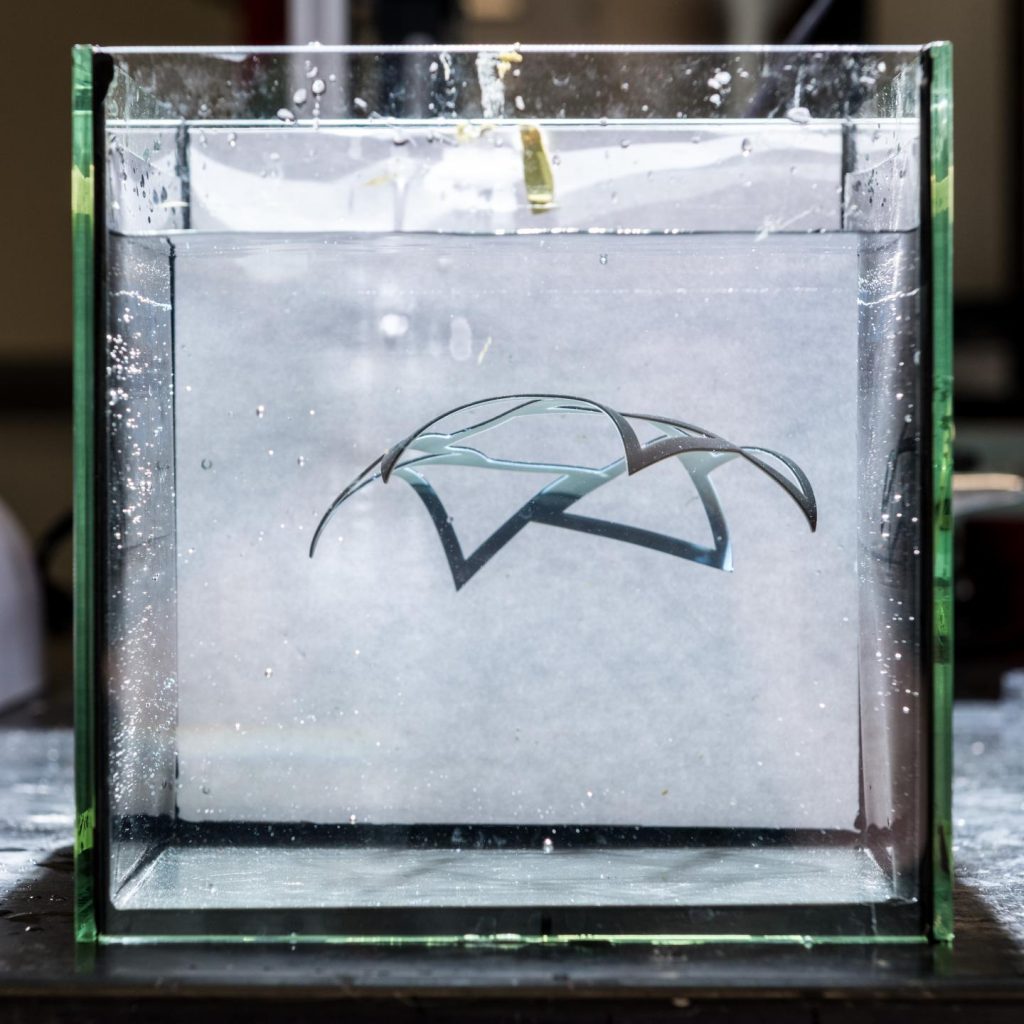

Self-assembly of a 4D printed from ETH Zurich. Clip via Engineering Design and Computing Laboratory on YouTube

A 3D printed, flat pack future

Typical examples of 4D objects include self-building flat pack furniture, and water activated scaffolding.

At present, the technology is expected to have the most impact in areas of construction and architecture. But, as a hot topic of research around the globe, studies continue to reimagine objects that can be made using 4D printing.

In addition to the clear benefits of self-assembling of objects, studies have also shown that 4D printing can dramatically reduce the amount of material used to make things.

A study led by the Georgia Institute of Technology 4D prints a dome that, if traditionally 3D printed, would usually use up to 8 times the amount of material, and take up to 8 times as long to make.

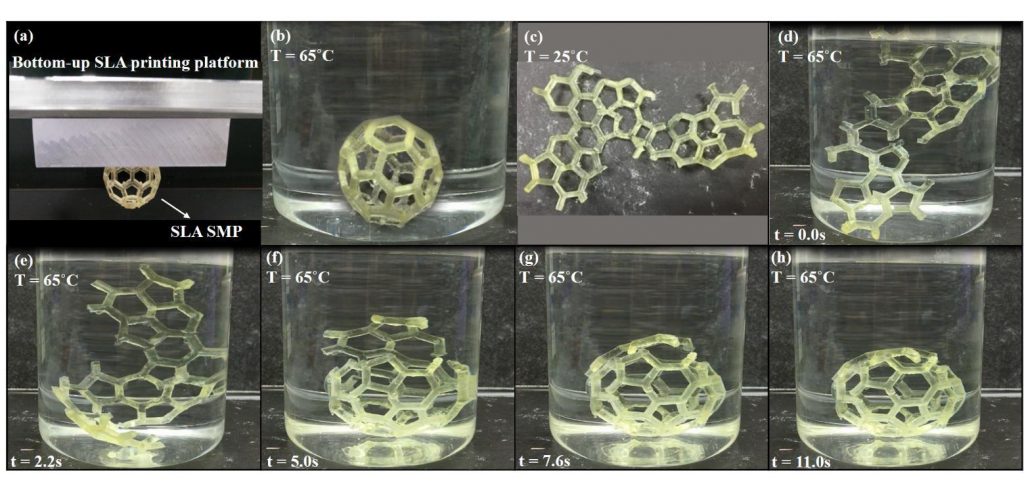

Another study conducted at the Singapore Centre for 3D Printing demonstrates a 4D printed bucky ball that is entirely support free.

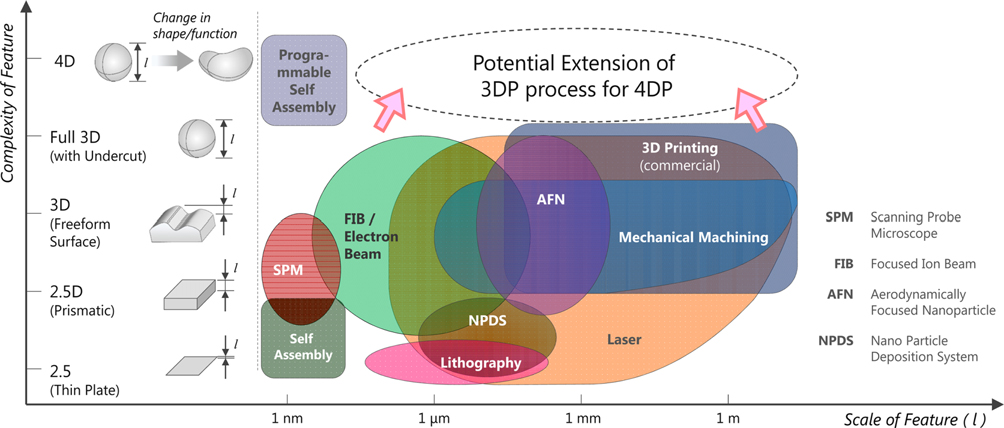

With potential to dramatically affect the way objects are designed and manufactured, a new study from Seoul National University (SNU) proposes a 4D printing roadmap to assess its role in the future.

“imitless opportunities” in engineering

limitless opportunities for innovation”. Innovation in this case applies to a comprehensive range of manufacturing techniques as detailed in the chart below.

The four conditions

Though the specified manufacturing techniques have the potential to extend into 4D, main stream integration relies on 4 conditions:

- First of all a “systematic and in-depth understanding of material related properties”.

- Second, a better understanding of fabrication techniques, and how they can be scaled up or down.

- Thirdly, improvements to technology that can be used to read the atomic and molecular structure of an object.

- And finally, development of powerful simulation tools that can accurately explore changes to all three variables.

A conceptual alloy

The four conditions form the basis of projections made by Chu et al. throughout the study, including a conceptual argument for 4D printing in metal.

The diagram above illustrates the structure of a 4D printable metal alloy.

In this concept, self-assembly would be made possible by precisely programming the position of an alloy’s atoms. It has the potential to be realized through further development of sub-micron 3D printing, as used to make the pencil-point castle at TU Wien.

Further reading

More insights from Chu et al. are available to read online in a paper titled From 3D to 4D Printing – Design, Material and Fabrication for Multi-Functional Multi-Materials.

Co-authored by Won-Shik Chu, Varsha Khare, Sanjiv Sonkaria, Gil-Yong Lee and Sung-Hoon Ahn, the article is is available to read, open-access, in the International Journal of Precision Engineering and Manufacturing-Green Technology.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image: Graphic demonstrating Einstein’s theory of relativity, where Earth stretches the fabric of space and time. Image via NASA