Are 3D printed pills the future? We visited a London laboratory to find out.

Established by academics from University College London (UCL) in 2014, FabRx is a company seeking commercialize 3D printed medicines and devices. On the principle that everyone is different, the vision of 3D printed pills it to be able to provide more personal and specific care to patients in need.

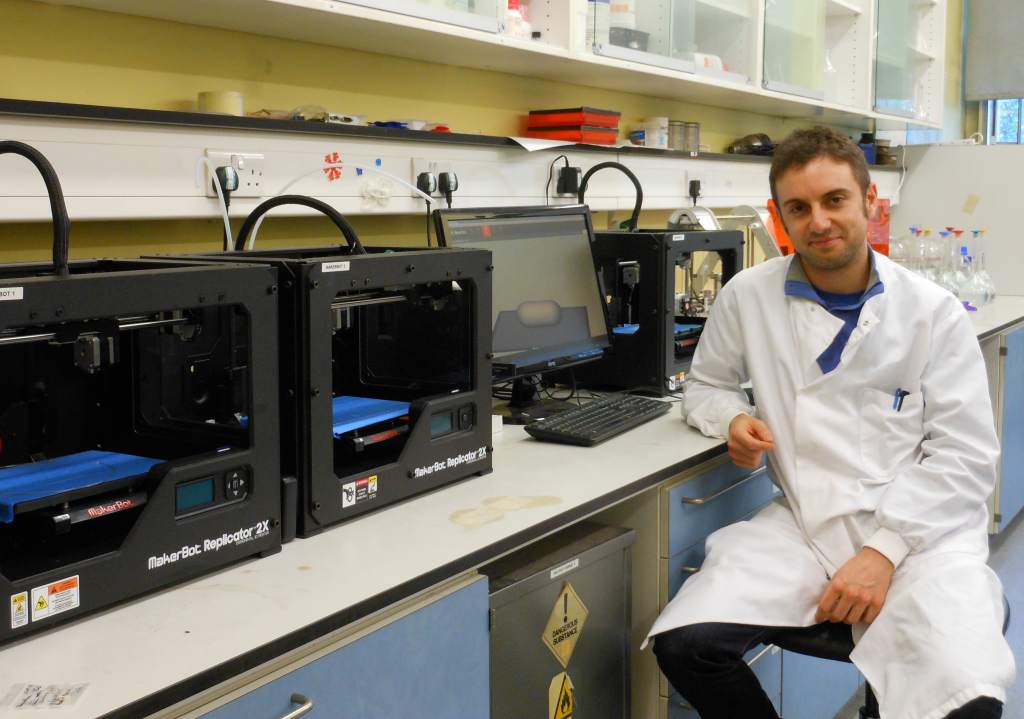

Dr. Alvaro Goyanes is one of the four founding partners of FabRx and the company’s director of development. Dr. Goyanes invited 3D Printing Industry into the lab at UCL’s School of Pharmacy to find out more about the ongoing FabRx research.

Placebos and paracetamol

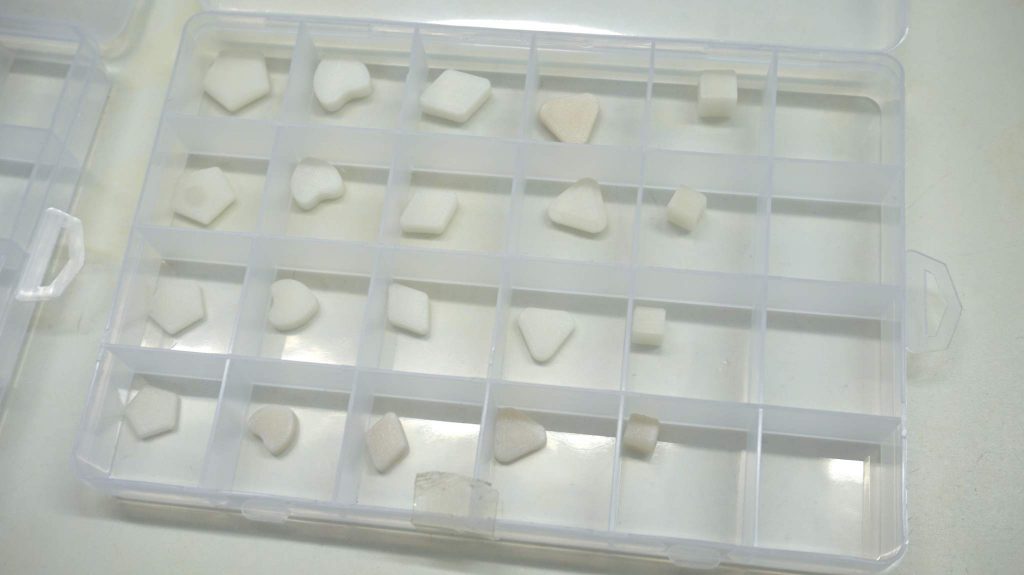

During a tour of the lab, Dr. Goyanes shows me the range of tablets the company have developed using their trademark Printlets technology. The pills are all 3D printed using the FFF method, and are made from the enterprises’ own filament.

The lab is equipped with a MakerBot and a four nozzle 3D printer that can print in multiple materials. Dr. Goyanes explains that within a 3D printed tablet,

The different layers could be different drugs, or one drug that is going to release fast in the stomach, and the same drug that is going to have a sustained release effect. […] So we can control how this is going to dissolve.

At this stage, 3D printed tablets from FabRx are either placebos or contain varying concentrations of paracetamol.

Treatment that comes in all shapes and sizes

Placebo Printlets are made from proven biocompatible excipients that dissolve in the body, and some are colored using the kind of food dye found in supermarkets. By contrast, 3D printed paracetamol tablets have currently only been used for pre-clinical trials.

The variety of placebo tablets also include different shapes that the lab has been experimenting with to see how people respond to them.

Dr. Goyanes explains the thinking behind the shapes,

For personalized medicine we always talk about how you can change the size, and in changing the size you adapt the dose of the formulations to the specific needs of each person. You can change the size, but you can also change the shape, so for example we are doing a study where we are trying all these crazy shapes.

Considering this unusual 3D printed structure of Printlets, human tests have so far had promising results. All 30 people asked to try the tablets were positive about the structure and the technology, showing preference only for particular colors or shapes. Full results of this study are due to be published later this year.

Making treatment personal

Moving away from the traditional mass-produced approach to medicines, Dr. Goyanes explains,

Our idea here is to get these printers into hospitals or pharmacies. We will supply the filaments, or the raw materials, and then the medical doctor, or the pharmacist will select the right dose for the patient, maybe combine different drugs, and just click the button, print and then this medication is given to the patient.

He does add, however, that there is still some way to go. When asked about the main barriers to 3D printed tablets, Dr. Goyanes says “The technology is there already, it is just the regulations that we have to get through.”

Proximity to the 3D printed pill

3D Printing Industry saw more of the latest in 3D printed pharmaceuticals at 2017’s 3D Medical Expo in Maastricht. One alternate approach to 3D printed pills is through the use of inkjet 3D printing. An example of this process can be found in research from a group at the University of California in Los Angeles (UCLA) that, in February 2017, published findings on a promising 3D printable bioink.

Spritam, the first 3D printed tablet to be approved by the FDA also uses this technique, but it it still for mass production of medicine rather than the personalized approach.

To stay up to date on the latest developments in 3D printed pharmaceuticals, sign up to the 3D Printing Industry newsletter, and follow our active social media sites.

Don’t forget to vote in the first annual 3D Printing Industry Awards.

Featured image shows spherical tablets 3D printed in two materials at FabRx. All photos featured in this article, unless otherwise stated, feature property of FabRx and were taken by Beau Jackson.