The University of Wollongong in Australia is quickly establishing itself as a premier institution for unique 3D bioprinting research. The school, which offers the world’s first masters degree in bioprinting (in tandem with a few other universities), has also been pursuing interesting projects involving the use of seaweed in 3D printing. Most recently, a professor at the school is developing 3D printed, edible sensors, according to IEEE Spectrum.

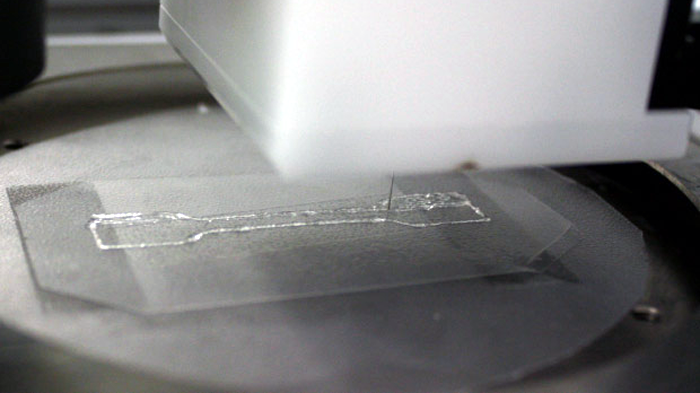

At a presentation at the Materials Research Society’s Fall Meeting in Boston, associate professor of chemistry and head of the soft materials group at Wollongong, Marc in het Panhuis, his team’s research to 3D print edible hydrogels capable of conducting electricity. The purposes, in het Panhis says, “is that we can eat our electronics and then they can perform a function and naturally go away.” Hyrdogels typically used in bioprinting research are too fragile for such a goal, so the team is creating more durable hydrogels by cross-linking multiple gel materials. Such mixtures include combining genipin, the anti-inflammatory agent in gardenias, with gelatin or gellan gum, the thickener found in jellies, jams, puddings, and other foods. In the 3D printing process, the material would begin as a liquid, like freshly mixed Jell-O, and then set into a gel over the course of a couple of hours.

To crosslink the two materials, the group is adding table salt. By soaking the gellum gum hydrogel in salt for a week, the material swells and becomes more stable. in het Panhuis explains, “Together this gives you a really tough gel.” Due to the fact that the hydrogels are up to 97.5% water and the addition of salt makes them even more conductive.

As the studies have only just begun, in het Panhuis is till only proposing its applications, but he believes that it may be possible to 3D print biomedical sensors that can be easily ingested. Issues associated with such devices is how to capture data from the devices and how to make the devices small enough to eat. The group has received seven years of funding and in het Panhuis claims that the team could yield such devices during that time.

Outside of edible sensors, the professor is also exploring soft robotics running on biocompatible actuators for sensing and controlling the pressure of a prosthetic hand, as well as soft, conductive materials for 4D printing. If he can get access to the Rapid 3D Nanoscale Printer based at Melbourne’s $30 Million MicroNano Research Facility, his research could get a nanoscopic push.