Laponite, a synthetic clay that becomes a clear gel in water, has been used to make a bioink for 3D printing powered medical studies. Commonly used as a thickener in cosmetics, the clay is a novel addition to hydrogels used as a habitable environment for stem cells, and biodegradable containers for controlled drug delivery.

In a study by the University of Southampton and Technische Universitat Dresden (TU Dresden) researchers prove that Laponite’s addition to bioinks performs better than its traditionally manufactured counterpart.

“Everything flows”

Addition of Laponite increases the shear thinning of a hydrogel when it is extruded through the nozzle of a 3D printer. In the same way that ketchup flows from a bottle when force is applied, Laponite ink decreases in viscosity which is helpful to the layer-by-layer deposition process.

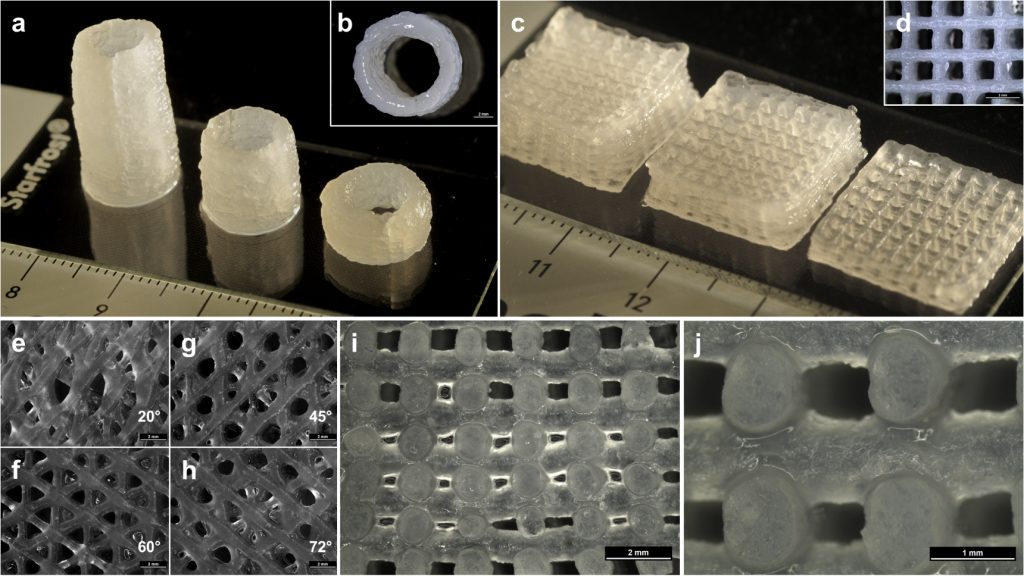

Upon deposition the ink regains viscosity, holding the shape of the desired structure, which in this case is grid-like cell scaffolds.

These rheological properties help the ink overcome some of the key challenges of 3D bioprinting. Speaking to Medical Physics Web Richard Oreffo of the University of Southampton explains, “The inclusion of Laponite into bioinks enables development of new compositions due to the interesting interaction capability of Laponite with polymeric hydrogels.”

Living cells and drug delivery

Alginate particles in the Laponite hydrogel become semi-solid (crosslinked) when incubated with calcium. Over time the flexible scaffold softens which indicates that it could be absorbed by the body.

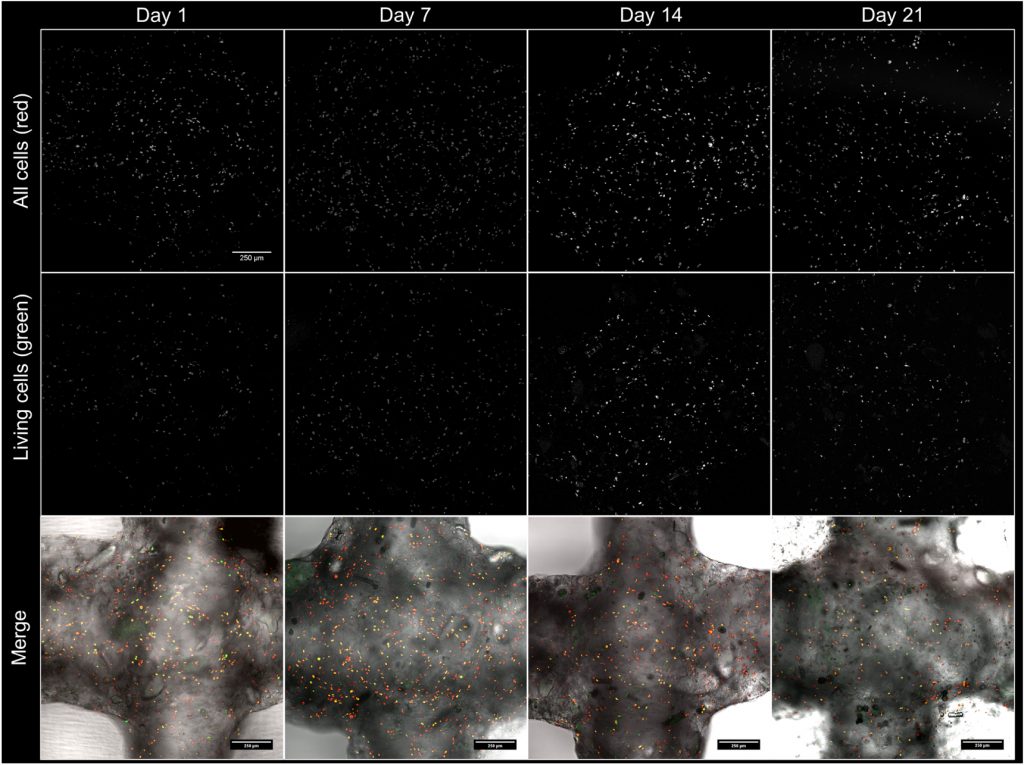

Lacing the Laponite gel with an immortalized human stem cell line (hTERT-MSC), researchers found that 70% of the organisms were still viable after 21 days. In a further experiment, where proteins were encapsulated inside the ink, researchers also proved that the material would be suitable for sustained drug release.

Next steps

Oreffo comments,”The bioink consisting of Laponite, alginate and methylcellulose showed advanced printing properties and a positive cell survival rate.”

“Our next steps,” he adds, “will focus on enhancing the cellular response within these printed constructs, either by subsequent preservation of the crosslinked state of the scaffolds or by usage of the attractive growth factor binding capabilities of the bioink with proteins that enhance cell responses.”

3D Printing Industry previously came across Oreffo’s work in 2014 when he helped Southampton General Hospital make a bespoke hip implant for 71-year-old patient Meryl Richards.

Oreffo’s most recent study, conducted in collaboration with T. Ahlfeld, G. Cidonio, D. Kilian, S. Duin, A. R. Akkineni, J. I. Dawson, S. Yang, A. Lode and M. Gelinsky is available open access in Biofabrication journal.

Read about more of the latest research projects in the 3D Printing Industry newsletter, on Facebook and on Twitter.

Register on our 3D printing jobs site now.

Featured image: Microstructure of 3D printed clay scaffolds seen in a cross section on day one of the University of Southampton/TU Dresden experiment. SEM image via Biofabrication journal