As I’ve said before, the TCT was such a big show that one simply couldn’t finish visiting all the booths within a short day. The use cases presented here are those impressed me by coincidence. Let’s have a good look at them.

Warwick Submarine

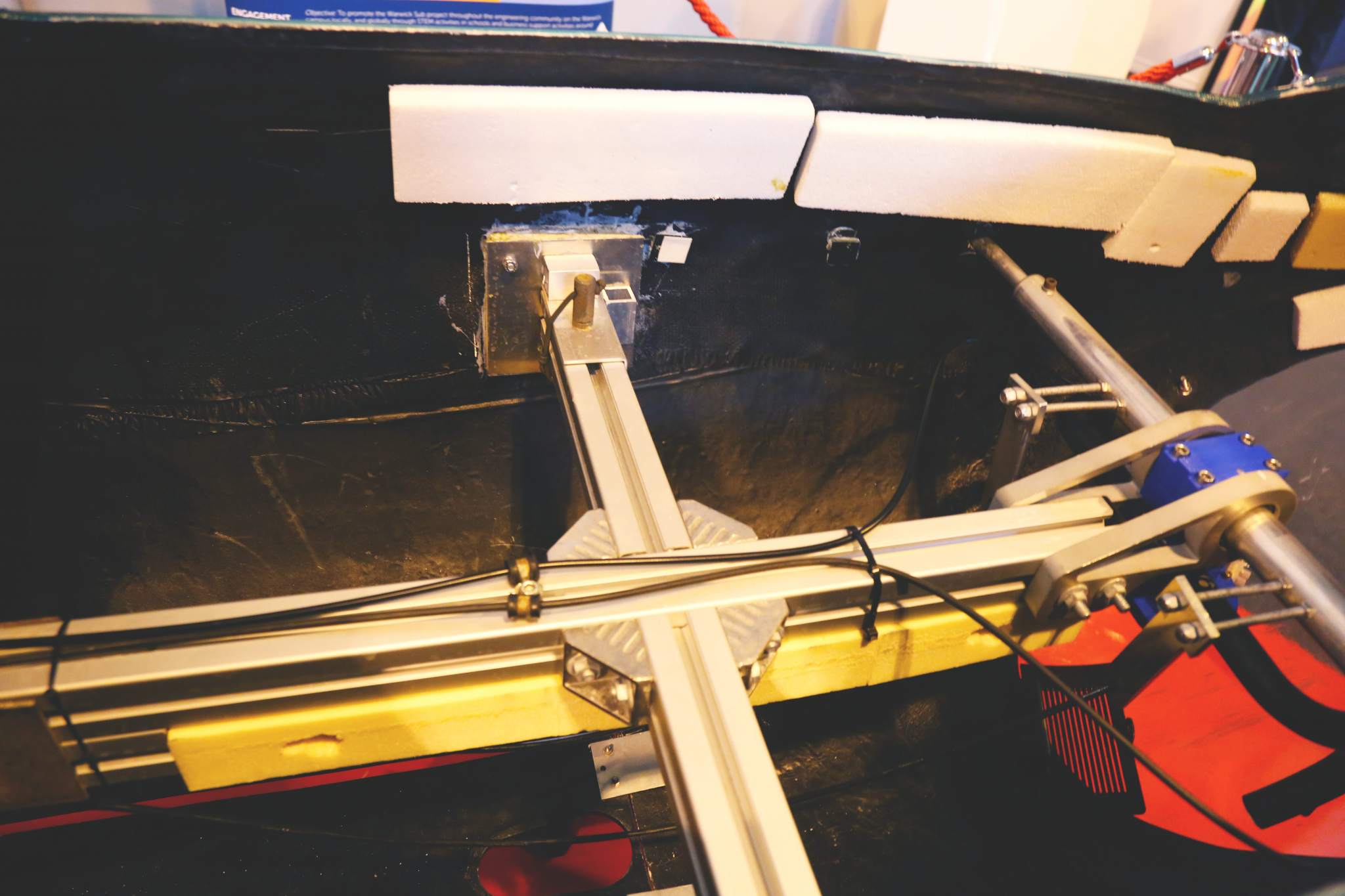

The first thing to caught my eye in the TCT Show is this awesome submarine. It is designed and built by engineering students at the University of Warwick and has brought home a prize from a European racing competition.

Dubbed Godiva 2, the Warwick team’s vessel is said to feature numerous 3D printed parts designed to withstand the challenging environment in which it will race. These parts include the fins, and the feet in which they sit, the propeller shroud and blades, plus a number of fixings, housings and internal steering components.

The project is made possible through the generous aid of a wide range of sponsors and technical partners, including: Concept Group International, Stratasys, WMG, the University of Warwick’s Innovative Manufacturing GRP, HVM Catapult, DIAB, Bosch-Rexroth Group, 3M and Apeks Aqualung.

3D Printed Speaker

We’ve seen 3D printed speakers before. The reason I would like to share with you about this speaker is simple – it is really cute and well made. As a music hobbyist, I certainly couldn’t ignore this lovely gadget.

This speaker is a use case from Mass Portal SIA. The Latvia-based company is a privately held enterprise that designs, manufactures and sells high definition, “open materials” desktop 3D printers.

Mid-2015 Mass Portal® Pharaoh® 3D printers are working.

High-resolution watch dial printed by Mass Portal® Pharaoh® 3D printers.

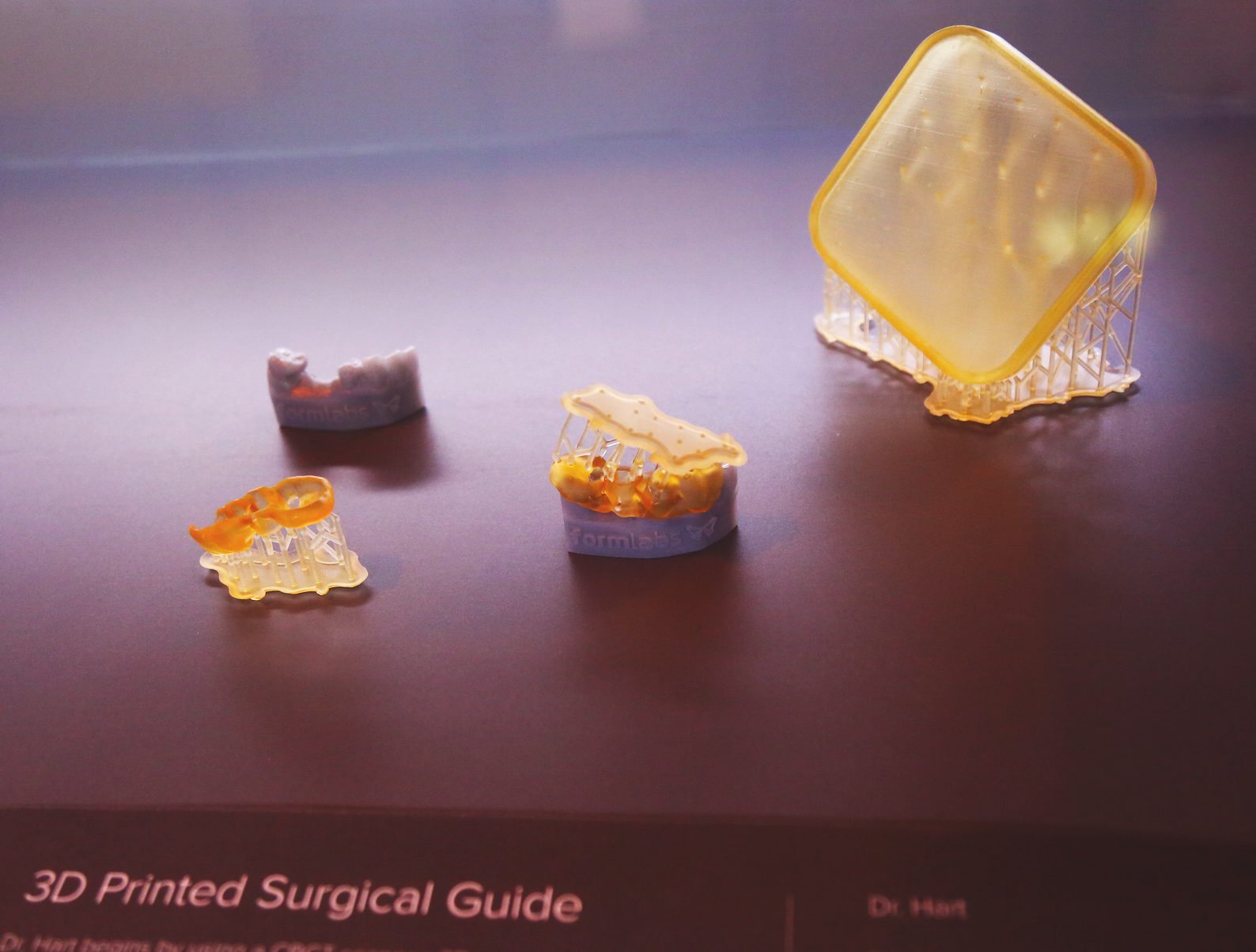

Surgical Guide and Jewellery

Dr.Hart, an expert in digital implantology and digital dentistry created these fine surgical guides with Printer Form 2 from Formlabs.

He begins by using a CBCT scanner, 3D scanner and modeling software to produce a scan of a patient’s teeth. Then he prints several slightly different models of the surgical guide on the Form 2 so that he can have options during the surgery. After printing, he removes supports, post-cures the part, and sterilizes it in an autoclave.

Dr. Hart was able to recoup the cost of his Form 2 after 20 cases.

These are some amazing jewelleries made with Form 2.

Apart from appreciation of these beautiful use cases, we will present more technical news in the following article.

Feature Image: 3D Printing Industry