Researchers at the University of Texas at San Antonio (UTSA) have received a $659,970 grant from the US Department of Defense’s (DoD) Army Research Office to improve the reliability of metal 3D printing processes.

Using computational designs, the project is seeking to improve the US military’s capabilities to produce parts using additive manufacturing for critical machinery, including its aircraft.

“One of the challenges of metal AM is the difficulty of knowing with 100 percent certainty what the mechanical properties (such as stiffness and strength) are in the printed components,” said David Restrepo, Assistant Professor in UTSA’s Department of Mechanical Engineering. “It is also challenging to predict or reduce the dimensional variability of the components when compared with the design specifications.

“These challenges mean that printed parts currently cannot be certified to use in critical components – those that, if a failure occurs, may compromise human lives.”

DoD’s 3D printing adoption

Since unveiling its first official additive manufacturing strategy in February last year, the DoD has awarded numerous grants and contracts to advance its use of 3D printing in various defense-related sectors.

Shortly after announcing its 3D printing policy, the DoD awarded binder jet 3D printer OEM ExOne with a $1.6 million contract to develop a portable 3D printing factory capable of spare part production in the field. Housed in a 40-foot shipping container, the ‘rugged 3D printing pod’ will be deployable on land, sea, and air to support war theaters, disaster relief missions, and other remote operations.

The DoD has since handed a new round of funding to additive manufacturing data specialist Senvol to develop its Senvol ML machine learning software, and awarded 3D printed rocket maker Relativity Space an orbital launch contract to launch a payload into low-Earth orbit (LEO) using its 3D printed Terran 1 launch vehicle.

Most recently, the DoD awarded 19 university-led projects a total of $25.5 million to advance research into hypersonic flight leveraging technologies such as 3D printing. The contracts were handed out to members of the University Consortium for Applied Hypersonics (UCAH) and will focus on composite aircraft materials, flight control systems, and solid propulsion fuels among other areas.

Improving AM reliability

Led by Restrepo, the UTSA team is using the DoD grant to develop new computational designs that could lead to more reliable metal 3D printed products in the future.

While the customization and on-demand advantages of additive manufacturing are well known, the technology is still challenged in terms of part quality, particularly within laser sintering-based processes. In particular, the researchers have identified the uncertainty of the mechanical properties and stability of the components when the powder cools and solidifies as a significant challenge within current 3D printing processes.

“We are modeling the laser sintering process to predict the mechanical properties and dimensional stability of the components fabricated with AM,” Restrepo said. “The unique ingredient in our models is a UTSA-developed technology for sensitivity analysis. This unique technology will allow us to predict the mechanical properties, reliability and qualifications of AM-generated parts.”

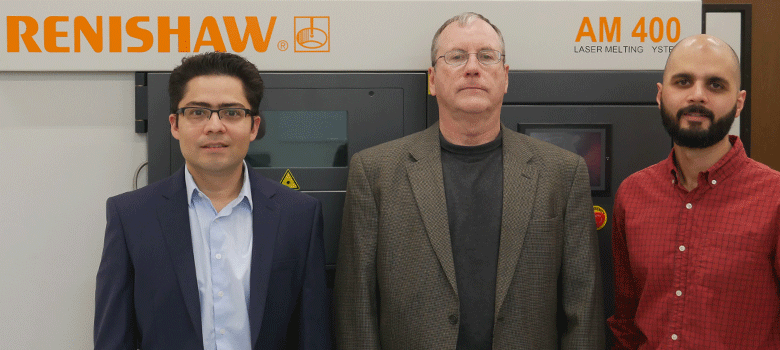

For the project, the team is utilizing resources within UTSA’s Makerspace, including a Renishaw 3D printer. The machine will help the researchers to fabricate parts and collect data that will either prove the effectiveness of their computational models or reveal changes they need to make to their calculations.

“UTSA’s state-of-the-art Makerspace offers technology to students and faculty that greatly expands opportunities to conduct research, explore and build,” said Harry Millwater, UTSA Professor. “The Renishaw 3D printer is an industry-leading tool that our students can work with throughout their time as a Roadrunner so they emerge ready to contribute to their careers from day one.”

According to Restrepo, the DoD project is also an opportunity for the university’s students to develop hands-on skills within additive manufacturing and other advanced technologies. The UTSA Classroom to Career initiative is key to giving students the skills demanded by employers, and this will prove important going forwards in order to fill current skill gaps in the additive manufacturing sector.

“Our students are offered many opportunities to develop hands-on skills through experiential learning opportunities, such as this research project,” said JoAnn Browning, Dean of Klesse College at UTSA.

“Our new MakerSpace and the technology it houses only furthers the potential for students to engage in unparalleled research and design opportunities, beginning as early as freshman year of their undergraduate degrees.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows UTSA researchers Arturo Montoya, Harry Millwater and David Restrepo stand in front of the Renishaw 3D printer at the Makerspace in the Science and Engineering Building. Photo via UTSA.