Researchers from Zhejiang University, China, have developed a new method of 3D printing electronic circuits using liquid metal microgels.

The novel approach involves encapsulating liquid metal microdroplets (specifically gallium) in alginate-based microgel shells to create a 3D printable and recyclable liquid metal microgel (LMM) ink. According to the team, the LMM ink solves many of the processability issues associated with raw liquid metals, enabling the printing of flexible electronics onto a wide variety of surfaces.

The Zhejiang researchers have already used their low-cost formulation to 3D print a near-field communication (NFC) tag onto a T-shirt, paving the way for smart e-clothing.

Working with liquid metals

You may have heard the term ‘liquid metal’ before – it’s used to describe metals that have melting points around room temperature, meaning they tend to come in a liquid state. Two of the more common liquid metals are mercury and gallium. Mercury has a lower melting point at -38.8°C, but it’s far too toxic to use in many day-to-day applications. Gallium, on the other hand, has a melting point of 29.8°C but is safe enough to use around human beings.

Since gallium features excellent electrical conductivity, the liquid metal has reportedly seen an uptick in interest in recent years. The material is considered ideal for conductive components, enabling novel applications in flexible electronic circuits, energy devices, wearable health monitoring devices, and even electronic skin.

Unfortunately, due to its high surface tension, gallium has a hard time forming continuous, complex patterns and likes to ball up into low-surface-energy spheres instead. This makes it difficult to pattern the liquid metal in its pure form into circuits and other high-precision devices.

3D printing a liquid metal microgel ink

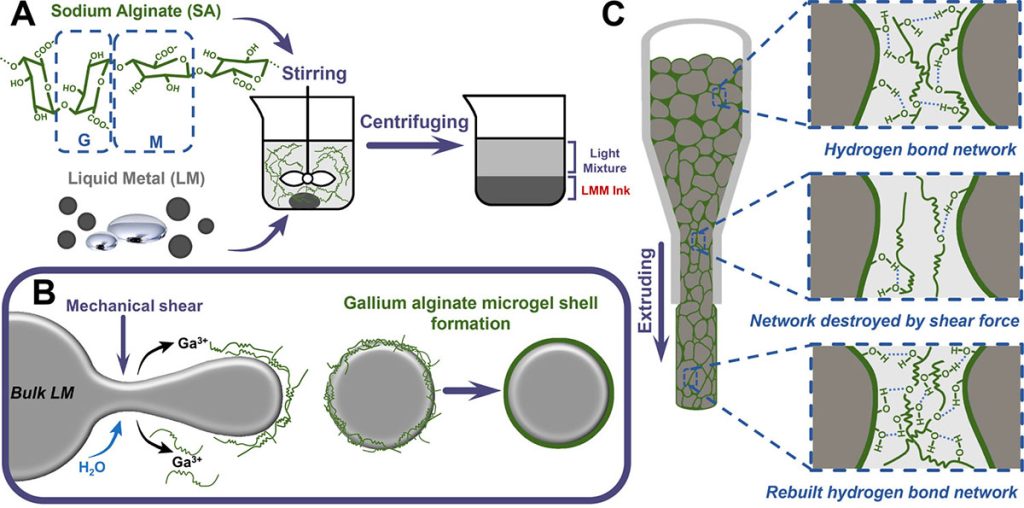

To address the issue of processability, the Zhejiang researchers simply developed their own 3D printable LMM ink. They did this by stirring gallium with sodium alginate aqueous solution, which cross-links Ga3+ with sodium alginate to form microgel-covered liquid metal droplets. The microgel shells are what improve the printability of the liquid metal droplets, enabling them to be used in the direct ink writing 3D printing process.

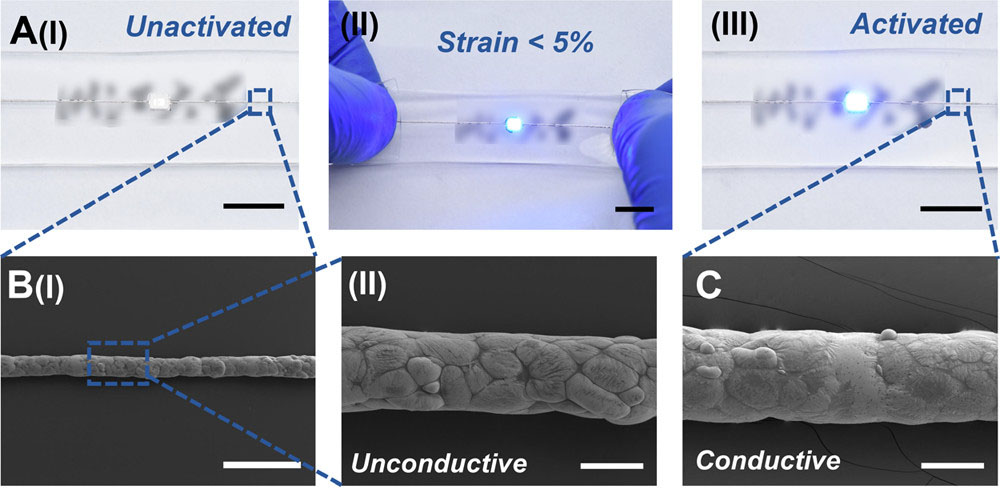

When initially printed, the LMM circuits aren’t actually conductive. But they can be activated by slightly stretching them as this breaks the non-conductive alginate bonds in the ink. Conductivity can also be re-activated by freezing and pressing the 3D printed LMM circuits, meaning they can be used in extreme environments such as outer space.

Upon testing the activated 3D printed circuits, the team found that they exhibited many of the characteristics essential for flexible electronics. This includes excellent conductivity, a significant resistance response to strain with small hysteresis, and great durability against nonplanar forces.

To test the performance of the 3D printed circuits on unconventional surfaces such as fabrics, they then 3D printed a flexible NFC tag on the front of a T-shirt. The tag can communicate with smartphones to execute a custom piece of code, in this case, automatically opening a webpage.

Ultimately, the team hopes that the combination of the low-cost LMM ink and the customization benefits of 3D printing can one day enable standardized smart e-clothing applications for personalized health monitoring, tactile sensing, and human-computer interaction.

Further details of the study can be found in the paper titled ‘Liquid Metal Microgels for Three-Dimensional Printing of Smart Electronic Clothes’.

Additively manufactured electronics certainly aren’t limited to the academic sphere, with more and more industrial organizations getting involved. Just last month, UK-based robotics firm Q5D Technology secured $2.5 million in seed funding to finance the development of a new multifunctional wiring and electronics 3D printer. Known as the ‘CU500,’ the 5-axis FFF system features a changeable toolhead capable of rapidly depositing polymers, metal pastes, and wiring onto large aerospace and automotive parts or electronic devices.

More recently, ETH Zurich spin-out Scrona AG raised $9.6 million to further develop its own high-resolution method of 3D printing electronic devices. Unlike conventional inkjetting, the firm’s Electrostatic Multi-Nozzle Printing process utilizes a piezoelectric field generated just outside the tip of a printing nozzle to jet multiple materials onto substrates at a sub-micron level of accuracy. The company says its approach allows for the creation of PCBs, semiconductors, and displays at resolutions 100x higher than before.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a T-shirt with an NFC tag 3D printed on the front. Photo via Zhejiang University.