For 3D printing to reach its true potential, there are a number of hurdles yet to be fully overcome, including the ability to cohesively — and cost-effectively — 3D print multi-material objects. The lab of Yong Chen, at USC Viterbi School of Engineering, however, may be onto a new technique that brings multi-material additive manufacturing closer to full realization.

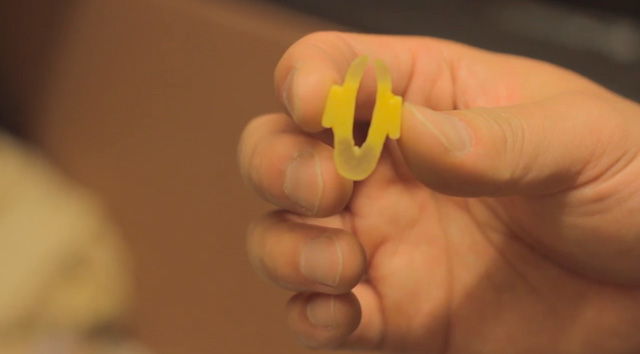

Professor Chen has developed a stereolithography (SL) method called mask-image-projection-based stereolithography (MIP-SL), which can not only speed up printing times, but also create objects with multiple materials that blend seamlessly into one another. With MIP-SL, a 3D model is sliced into a series of horizontal planes, with each slice translated into a 2D mask image. The image is projected onto a vat of resin, curing a given layer into its corresponding mask shape. In order to speed up the process, Chen’s team uses a bottom-up projection method, combined with a two-way movement design developed by the group last year, cutting the print speed from hours to minutes. Using the two-way movement process, in which the resin vat is moved left to right after shifting upward, the lab was able to print a heterogeneous object made up of materials that cure at different rates.

Chen describes the possibilities for the work, saying, “Digital material design and fabrication enables controlled material distributions of multiple base materials in a product component for significantly improved design performance. Such fabrication capability opens up exciting new options that were previously impossible.” Below, the professor gives an explanation of the project’s results:

3D Printing Multi-Material Objects Faster from USC Viterbi on Vimeo.

The software for this technique is not yet complete, but the professor plans to automate the design of materials with user-specified properties. The team’s findings were presented last week at the ASME’s 2013 International Mechanical Engineering Congress and Exposition in San Diego, California.