The German Engineering Federation (VDMA) and the German Machine Tool Builders’ Association (VDW) are collaborating to promote the use of OPC UA standards in the mechanical engineering sector under the Universal Machine Technology Interface (umati) standard.

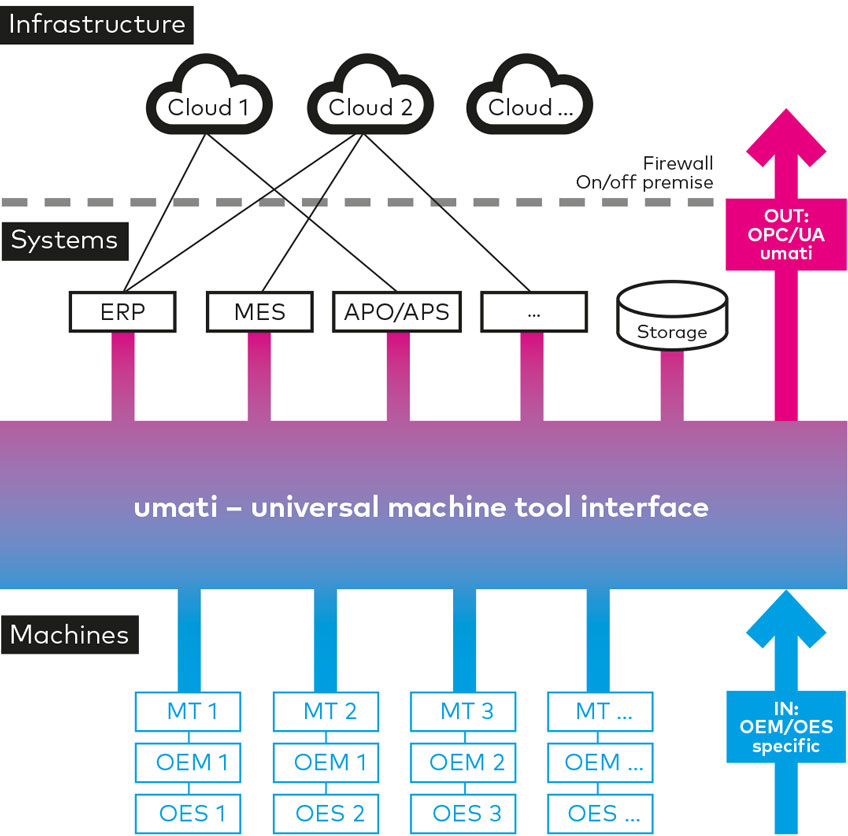

Launched in 2017 by VDW, umati aims to establish a worldwide standard for simple data transfer between various tooling machines, which includes 3D printing systems and production management software. As it is based on the OPC UA open machine-to-machine communication protocol, it allows devices across different industrial sectors to connect on one platform. Explaining the VDW and VDMA’s cross-technology strategy, Dr. Wilfried Schäfer, Executive Director of the VDW, states: “Cross-industry and cross-technology marketing will take our customers a significant step forward.”

“Manufacturing companies have not only machine tools but also their own individual mix of machines, equipment, robots and systems. If all these technologies can exist in a common ecosystem which is ideal for producing plug-and-play solutions, this will save end users a lot of time and money.”

The umati standard and 3D printing

The VDW, headquartered in Frankfurt am Main, Germany, represents the German machine tool industry to the public, the politicians, business associates and the academic community, both at a national and international level.

Together with the Sector Association Machine Tools and Manufacturing Systems within the VDMA, the VDW comprises 303 mid-tier companies as of March 2020. The VDMA itself represents around 3,300 SMEs in the mechanical and systems engineering industry in Germany and Europe.

In 2017, the VDW launched an initiative to create an open, standardized interface for machine connectivity. The organization opted to base its technology on the OPC UA protocol, as it provides a uniform framework for machine and system interoperability. This led to the creation of the Universal Machine Tool Interface (umati) working group and standard.

Major machine tool builders, including the likes of Trumpf and DMG Mori, committed themselves to the umati working group when the project launched. Two years later at EMO Hannover 2019, a demonstration of umati interface standard use cases took place, showing that it was possible to connect 110 machines to 28 software services distributed across the exhibition grounds.

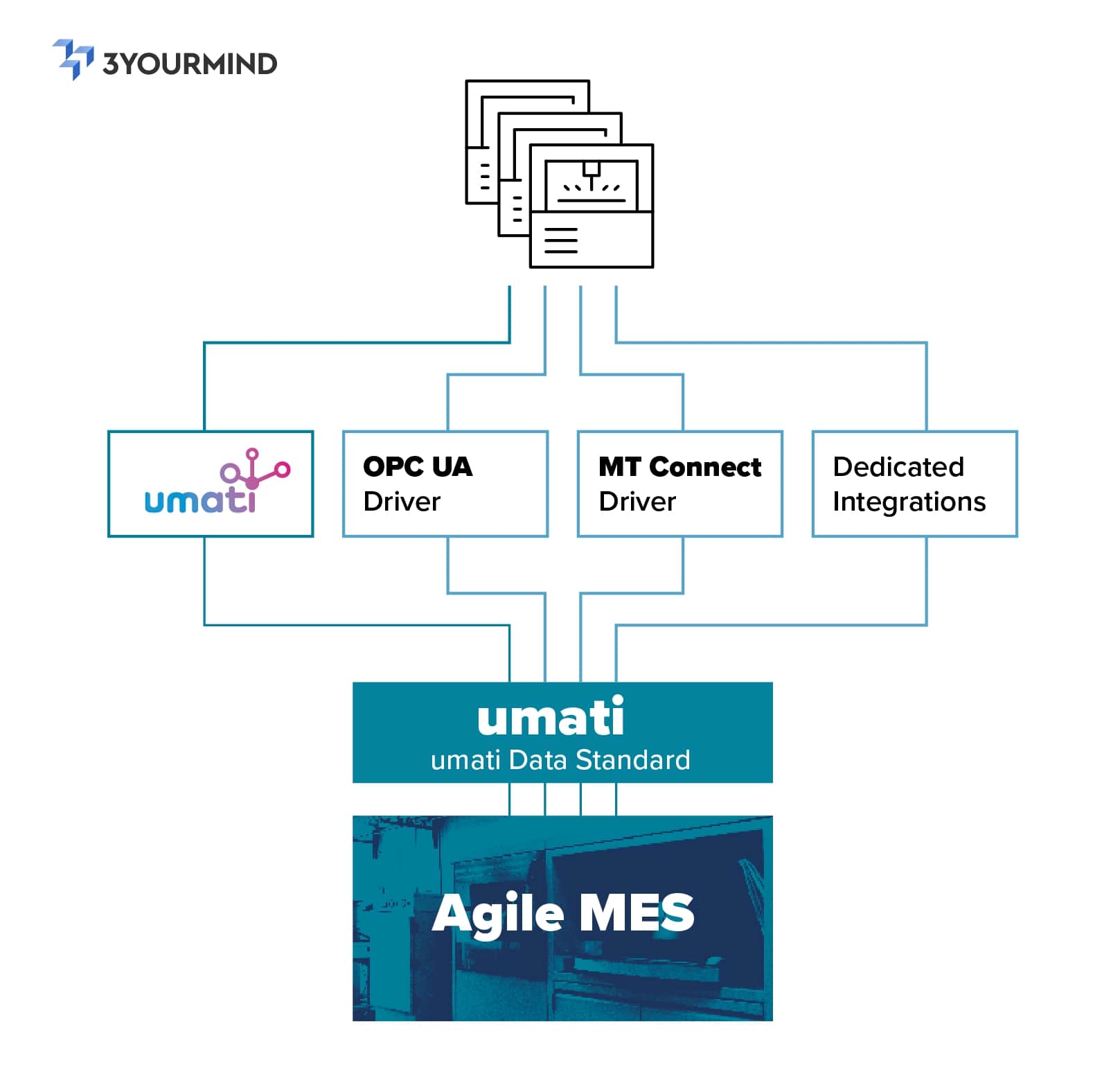

German 3D printing software developer 3YOURMIND joined the umati working group in August 2019, acting as the main software participant in the group’s work to employ the umati standard specifically for the additive manufacturing process chain. Seeking to enable automation and serial additive manufacturing in the process chain, 3YOURMIND opted to work with the umati standard as it is designed to operate with virtually all modern, automated production and post-processing machines.

The VDMA and VDW join forces

The mechanical and plant engineering sector has been an adopter of OPC UA as the standard for data exchange from an early stage. It was important for the sector to develop uniform definitions for basic elements of a diverse range of products in mechanical and plant engineering. As such, various VDMA departments, such as Electrical Drive Engineering, Plastics and Rubber Machinery, Machine Vision, Metallurgy, Robotics and Machine Tools, are working on establishing the Basic Companion Specification ‘OPC UA for Machinery’. “The first version is scheduled for publication later this year,” announced Hartmut Rauen, Deputy Executive Director of the VDMA.

“Over 30 specialist groupings in more than 17 associations are working on technology-specific interfaces, the “Companion Specifications”. This high level of collaboration forms the basis of true, open interoperability between machines and software systems, from the shop floor to the cloud. Only the VDMA has the means to unite the necessary integrative forces from the wide range of production domains,” added Rauen.

In order to give the VDMA Companion Specifications greater visibility and usage, VDW decided to extend the umati label to cover the entire mechanical and plant engineering industry for the use and promotion of the OPC UA standards. As such, umati was given a new name: universal machine technology interface. “The VDW and VDMA have decided to take care of this together in future. Production managers all over the world must be able to count on machines from any given manufacturer being able to speak the same language, thus turning the claim of umati – Connecting the World of Machinery, into reality,” concluded Rauen.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows diagram depicting the Umati universal interface for machine tools. Image via VDV.