Tomorrow doors open to the public for the year’s largest event dedicated to additive manufacturing.

Ahead of formnext 2019, I caught up with Aleksander Ciszek, CEO of 3YOURMIND, to find out what his company has planned for this year’s show and what not to miss during this busy week in Frankfurt.

3D Printing Industry: How has 2019 been for 3YOURMIND?

Aleksander Ciszek: It’s been a great year! Last year we were talking a lot about Serial AM, and in 2019 we are seeing customers who are actually putting it into practice. The most exciting example is ERPRO who are using 3YOURMIND’s Agile MES to track and validate the Chanel mascara brush production line. France took quite a big leap forward in terms of additive this year, with other prominent services (Initial, RapidManuf) scaling with support from 3YOURMIND. We also began working with some very interesting customers and applications in the US which we’ll be talking more about in 2020.

3D Printing Industry: What are some of the most interesting developments since you last exhibited in Frankfurt?

Aleksander Ciszek: Last year, additive was still seen as the outsider within the manufacturing ecosystem of most enterprises. This year, it’s clear AM has now been validated as a valuable production method in many of these cases.

It’s been interesting to see the amount of spare parts use-cases rise so dramatically. Deutsche Bahn, for example, manufactured a large-sized secondary roll stop, a security-critical part using 3DMP technology from GEFERTEC. It provided a massive time-saving for their operations division by cutting production time by 50%, while further verifying AM for safety-critical applications. The increase of distributed additive manufacturing for replacement parts is also one of the reasons we put so much focus on developing our digital inventory.

3D Printing Industry: How is your company tackling challenges in additive manufacturing?

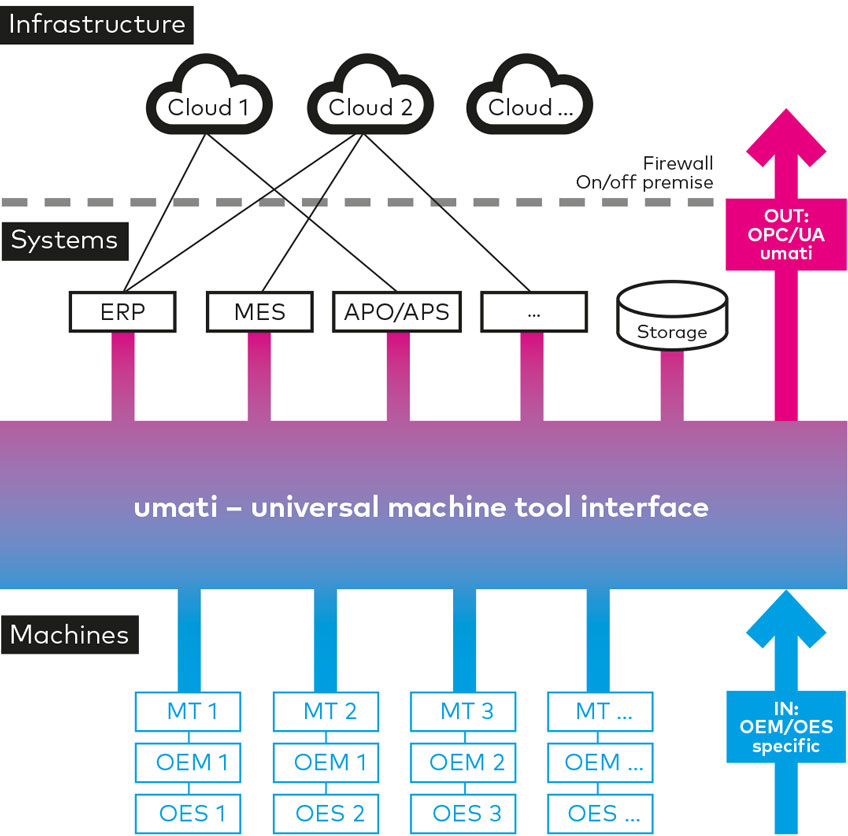

Aleksander Ciszek: The most significant obstacle that remains for scaling is getting better quality control information from the production floor in order to optimize machine utilization. We put in significant work over the last twelve months to develop a standardized data system with the umati working group. We feel our work with leading AM and post-processing machine vendors and researchers will improve how AM data is evaluated and delivered to machines. For our team, it was also important to work towards unifying machine data. We know that AM service bureaus have machines from two-ten different vendors. We want our software to be a centralized management point for repeat production across technologies, and that works hand-in-hand with the existing proprietary software from machine vendors.

3D Printing Industry: What are you looking forward to most about formnext 2019?

Aleksander Ciszek: For us, formnext is a very important touchpoint for connecting with our existing customers as well as meeting those still wondering how to best incorporate automation into their workflow experience. The majority of our time is spent demonstrating our updated software capabilities, gathering additional feedback and understanding what the most significant action points are to address over the following year. So the days are full, but we leave formnext with a spring in our step and ready to update our product roadmap for the year ahead! We’re also excited to be hosting our annual Rave Til AM party with our partners AM Ventures, DyeMansion, Ultimaker, 3D Printing Industry, and TüV SüD.

3D Printing Industry: What can visitors to your formnext booth expect to see?

Aleksander Ciszek: We will have live demonstrations of our machine connectivity using a small print farm of Ultimakers. For us it’s important we’re able to show our customers and the industry that our machine connectivity was conceived and created directly alongside vendors, and streamlines data into the single umati standard no matter how the vendor is capturing their data inside the machine. On the front wall, we will also be visualizing the capture of data from other machine types, regardless of whether they are running pure OPC UA, MTConnect or even their own custom API. Bosch Industrial Additive Manufacturing will also have a dedicated area of our booth to showcase how they are using our AM Part Identifier to validate use cases for their technology from throughout the Bosch organization.

Visit 3YOURMIND in Hall 11, floor 1 at booth E61.

The 3D Printing Industry team is back in Frankfurt for formnext this week. Get in touch if you’d like to meet. If you can’t attend the show, then follow our social media accounts on Twitter, Facebook, and LinkedIn.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Aleksander Ciszek, CEO and co-founder of 3YOURMIND. Photo via 3YOURMIND.