German railway company Deutsche Bahn is integrating metal additive manufacturing 3DMP technology from GEFERTEC to improve the availability of hard-to-procure spare parts.

The 3DMP process was implemented for the first time as part of this pilot project. According to Dr. Tina Schlingmann, a Senior Consultant of complete railway systems technology at Deutsche Bahn, availability is a big issue for the company. 3DPM is being used to service vehicles for older locomotives, including now obsolete parts.

Logistical additive manufacturing

Since 2016, Deutsche Bahn has expressed interest in using additive manufacturing to produce spare parts for its selection of trains. This led to the Mobility Goes Additive project which focuses on digitizing logistics for the billion dollar rail transport company through a digital spare parts warehouse using 3YOURMIND software.

One of many use cases leveraging 3D printing technology involves a wheelset bearing cover for a Class 294 locomotive, a model that was put into service over 50 years ago. The original casting for the cover measured 374 mm in diameter, 78 mm in height, and weighed 11.5 kg. Furthermore, this part takes approximately nine months to be delivered and without it, lubricant can leak out of the wheel, causing damage to the bearing.

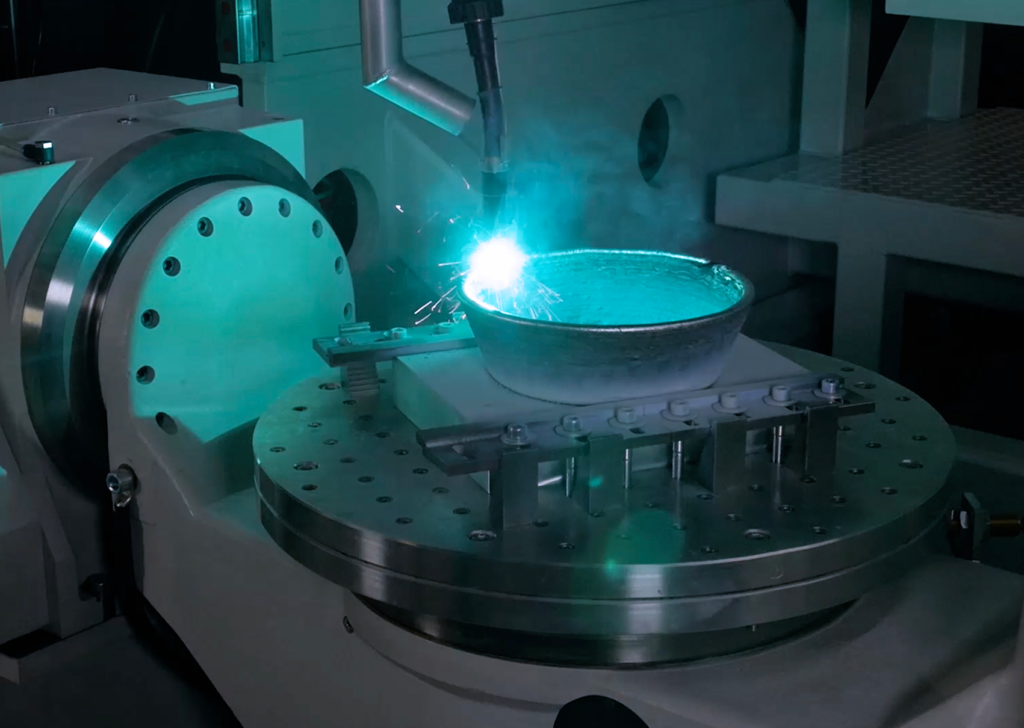

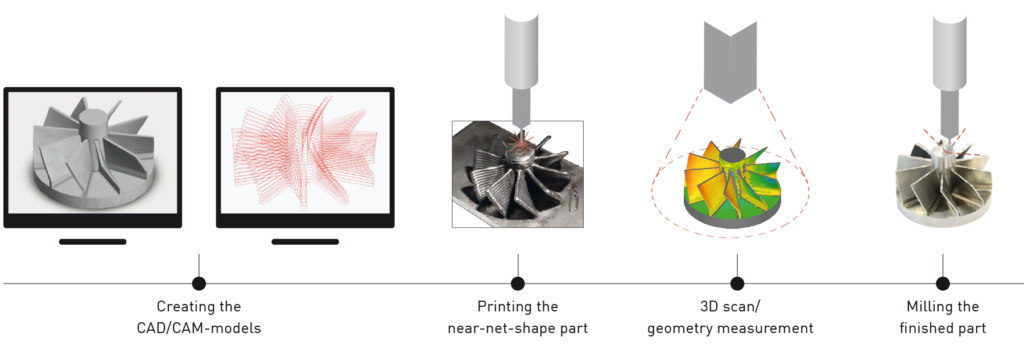

Rolf Lenk, a German manufacturer of industrial tools and machinery, who partnered with GEFERTEC last year, aided the company in 3D printing an improved version of this part using the Arc605. The design for this part is stored in the digital warehouse also known as a digital twin.

GEFERTEC’s 3DMP technology

As well as improving availability and significantly lowering manufacturing costs, Dr. Schlingmann noted that this approach can positively affect the environment, “Each component comes with a CO2 footprint that could be significantly reduced by additive manufacturing.”

The 3DMP process, in particular, enables rapid production of near-net shaped metal blanks using a wire as a raw material. This method is said to have an extremely high build-up rate of up to 600 cm3 per hour making it suitable for cost-effective production of larger workpieces made of steel, nickel-base, titanium or aluminum.

According to GEFERTEC, 3DMP technology promises to eradicate waste with “nearly 100% material utilization,” and cost savings of “up to 60% versus conventional manufacturing.” Dr. Schlingmann believes this technology is perfectly in line with the Deutsche Bahn “This is Green” environmental campaign.

Want the latest additive manufacturing news? Subscribe to the 3D Printing Industry newsletter and follow us on Twitter and Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows different types of Deutsche Bahn trains. Photo via Deutsche Bahn.